|

BMe Research Grant |

|

Pattantyús-Ábrahám Géza Doctoral School

Department of Machine- and Product Design

Supervisor: Dr. Tibor Goda

Material and frictional behavior of rubber sliding on glass surface

Introducing the research area

Nowadays, a growing research interest can be

experienced related to the sliding friction, which is generally called tribology

in the literature. However, the study of sliding components shows considerably

differences. Meanwhile, more complicated and sophisticated models and

experimental results come to light for the examination of seals, the research of

windscreen wipers started to be an examined field just in the last few years.

However, the literature still can not provide a comprehensive picture of

the operation, which would be essential for the development, because the

literature uses only specimen-level studies, which are not suitable for the

explanation of all structure-based phenomena.

only specimen-level studies, which are not suitable for the

explanation of all structure-based phenomena.

In my work, I attempt to conduct a comprehensive study, covering the strain, time and temperature dependent material laws and determine the parameters in them. I examine the dry and wet sliding friction of wiper blades on a glass surface, and I will try to calculate the lubrication state between the two contact surfaces with modern numerical calculations.

Brief introduction of the research place

I do my research at the Department of Machine- and Product Design. The department is involved in the education of many faculties and the whole mechanical engineer education both on BSc and MSc levels. The nearly 70-strong community takes part also in basic and applied researches and experimental development activities of many areas, which belong to the department's profile. In doing so, we have been maintaining good technical relation with national and international partners for a number of years, in which our talented and diligent students can actively deepen their knowledge.

.

History and context of the research

I started the related examinations during the development of my MSc thesis, when I had the opportunity to join to a EU6 project (KRISTAL EU Project Reference NMP3-CT-2005-515837, Oct. 2005 – Sept. 2009). The main goal of the project was to examine the mechanical and tribological properties of elastomeric components produced by industrial partners. Further motivation was to create the opportunity to numerically model them by finite element simulations. After graduation I started my PhD studies in the frame of the doctoral school. In the center of my interest is a custom commercial component, namely the windscreen wiper. The aim of my study is providing a general picture to help understand the sliding friction of this rubber component operating in realistic working conditions. During my study, I work out analytical and numerical models and also spend time to examine the material laws, and the parameter identification methods thereof.

![]()

The research goal, open questions

The main motivation of my work is the tribological (frictional and lubricational) examination of a commercial windscreen wiper. During my work, I also use simplified (specimen level) and complex, application like (structural level) test configurations. To my best knowledge, the complex case has not been examined in the literature as yet. The test results include normal and friction force values under various sliding velocities and loads. Furthermore, outputs are the coefficient of frictions, the change of the apparent contact area and the emerging fluid film thickness between the surfaces. One part of the results come from numerical simulations, which require the parameter identification of material models in order to ensure the facility to take into consideration the well-known stain, time and frequency dependent behavior of rubber like solids. During my work, I also concentrate on the development of a method which uses cheap and yet available test configurations for parameter identification.

The questions to be answered are as follows.

-

How can be described the non-linear time and frequency dependent behavior of rubbers and rubber-like materials?

-

How can be widened the measurable time/frequency domain by using the so-called time-temperature superposition?

-

How can material model parameters be identified from measurements available in most cases and how wide is their application range?

-

How can be widened the application range of these methods?

-

Which phenomenons influence the rubber-glass contact process and frictional behavior?

-

What is the effect of water on the frictional behavior and lubrication of windscreen wipers under wide range of sliding speeds and loads?

-

What is the interrelation between the specimen and structural level tribological behavior?

Methodology

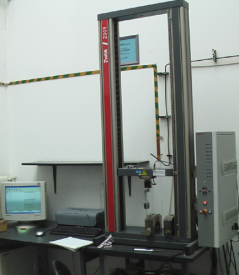

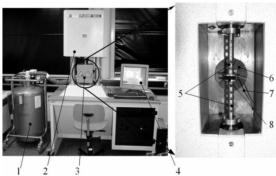

My research can be regarded as material science and tribology at the same time, which is based on experimental studies. Accordingly, I created a large number of measurements both in the testing labs of domestic universities and German research institutes. In the Department of Polymer Engineering (Technical University of Budapest, Hungary) in the Biomechanical Resource Center (Technical University of Budapest, Hungary) and in the Composite Mechanical Institute (University of Kaiserslautern, Germany) I created a large number of uniaxial, stress relaxation tests and DMTA (Dynamical-Mechanical-Thermal-Analysis) measurements. The tests aimed at the examination of special temperature and frequency dependent material characteristics of rubbers. The measured results also allow to examine the mathematical description of the so-called viscoelastic and hyperelastic material laws, which are designed to model the time, temperature and stain dependent material behavior.

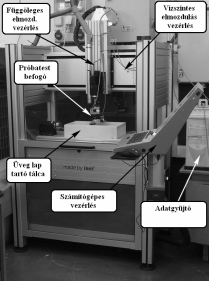

In the Department of Machine- and Product Design I

built a self-planned testing rig, which is suitable for the examination of the

specimen level behavior of a wiper blade, under dry and lubricated conditions.

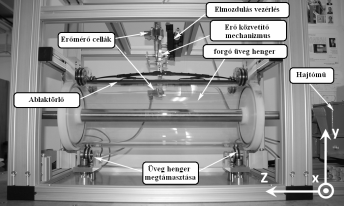

In the Institute of Dynamics and Vibrations (University of Hannover, Germany) I

tested the structural level behavior of a wiper blade not dealt with in the literature as yet.

All measured results are supported with corresponding finite element

simulations, which are dedicated to give valuable explanations on the measured

characteristics and give results that cannot be acquired through measurements. All

conclusions are formulated from the executed measurements and

calculations.

Results

I have developed a new method for the identification of small-strain based generalized Maxwell-model (commonly used mathematical model containing linear springs and dashpots) parameters from constant strain-rate uniaxial tension tests. I verified the method applying five or less Maxwell-terms by using self-made experimental results measured on Isoprene rubber specimens. With the proposed tensile test based technique the parameters of viscoelastic models can be determined through minimal efforts, with the accuracy generally required by engineering calculations in a transparent and easily digestible way. I also extended the method for large-strains. By the modification, the method can be also effectively applied to identify the (Green strain tensor’s) invariant based hyperelastic model parameters. With the extension, additionally to the viscoelastic parameters the strain-dependent parameters can also be easily determined from two tension tests applying constant but different strain rates. I have proven the validity of the method by self-made experiments and it is established that the parameters can be dependably calculated within 5% precision which is acceptable in engineering calculations.

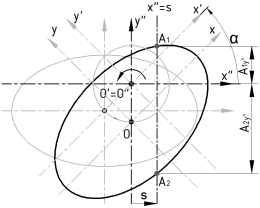

During the tribological tests, I have

created structural-level measurements in order to examine the real behavior of

the windscreen wiper. Unfortunately, the test results cannot be directly

evaluated because of the irregularities and eccentricity (difference between the

geometrical and rotation centers) of the rotating glass cylinder surface applied.

Therefore, I have developed a mathematical model in order to explain and evaluate

the whole, structural level tribological measurement performed on the windscreen

wiper. The model creates connection between the surface shape irregularities and

eccentricities and cyclic fluctuation of measured normal and friction force

components.

By applying the method, I have ascertained that the experimental results are strongly affected by the eccentricity and the real, non-circular cross section of the glass cylinder. I have also proved by examination of force balance, that in spite of the asymmetric contact the measured force components can be regarded as normal and friction forces.

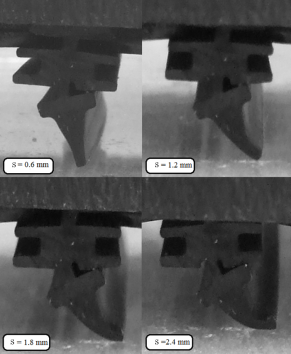

Using the structural level examination of partial windscreen wiper/glass contact, I have proved that the normal load per unit length values can be considered to be independent of the operating parameters which are able to cause one order of magnitude difference in coefficient of friction, due to the changes in the apparent contact area. This effect cannot be observed when we can realize total contact, which is generally detailed in the literature.

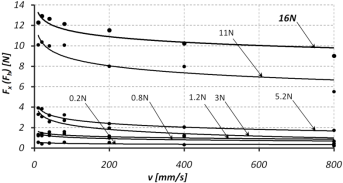

The measurements pointed out that with

increasing sliding velocity or load the friction coefficient decreases, similarly

to the specimen level examinations. In the structural level examination, the

apparent contact length of the windscreen wiper changes, which results nearly the

same normal load per unit length values in spite of the increasing normal load.

All these predict the evaluation of the same tribological situation under

different operating parameters, which cannot be experienced in specimen level

examinations.

I also performed measurements at specimen level. According to the measured normal and friction forces, I have concluded that the dry friction coefficient dependence on the windscreen wiper blade has logarithmic shape and inversely proportional with the normal force. With water lubrication, the increasing sliding velocity (between 1 mm/s to 150 mm/s) decreases the coefficient of friction from 1.6 to 0.6 in an exponential tendency on the maximal examined load. By using numerical simulations (finite element simulation) I have established that the nominal contact width can also show increasing and decreasing tendencies by increasing coefficient of friction. According to my test results, the transition between the two tendencies can be experienced when the load per unit length value reaches its value of 25 N/m.

Expected impact and further research

The above research results are communicated in 18 published, 3 accepted, and 1 submitted papers. From these publications 14 are published like reviewed paper or journal paper in foreign language (English). I would like to mention two of the published papers that earned impact factor in the journals of Web of Science (WoS), and the further 6 publications which are published in the papers of Scopus. The accepted publications will be available as conference proceedings, while the submitted one also connects to a Scopus journal.

Furthermore, I need to mention that the results of specimen-level examinations are not fully published as yet, therefore, I will submit a new article in the near future, which hopefully will also get an impact factor. Beyond the written publications, I also gave 14 oral and 4 poster presentations in the last few years.

Publications, references, links

Publications

[1] G. Bódai, T. Goda: Friction force measurement at windscreen wiper/glass contact, Tribology Letters, Vol.45, Nr.3 (2012) pp. 515–52, IF:1.574 (2010),

[2] G. Bódai, T. Goda: Identification of large strain viscoelastic parameters of generalized Maxwell-models: Application oriented approach for engineers, Acta Polytechnica Hungarica, Vol. 8, 5(2011) pp. 89-108., IF: 0.284 (2010)

[3] G. Bódai, T. Goda: Parameter identification methods for spring-dashpot material models, engineering approach for small strain elasticity, Materials Science Forum, 659(2010) pp. 379-384.

[4] G. Bódai, K. Váradi, L. Molnár, L. Oroszváry: Temperature dependent Examination of Brake Cylinder Membrane (Part I), FE Modeling of the Tension Examination of Cord-reinforced Specimens, Periodica Politechnica, 54/1 (2010) pp. 3–8

[5] G. Bódai, K. Váradi, L. Molnár, L. Oroszváry: Temperature-dependent Examination of Brake Cylinder Membrane (Part II) FE Modeling of Cord-reinforced Rubber Membrane Behavior, Periodica Politechnica, 54/1 (2010) pp. 9–13

[6] L. Molnár, K. Váradi, G. Bódai, P. Zwierczyk: Simplified modeling for needle roller bearings to analyze engineering structures by FEM, Periodica Politechnica, 54/1 (2010) pp. 27–33

[7] G. Bódai, K. Váradi, A. Szabó, L. Zóbory: Thermal simulation of pin on rotating cylinder jacket system, article submitted to Periodica Politechnica

[8] G. Bódai, T. Goda: Identification of the wiper blade coefficient of friction, XVII International Conference on Mechanical Engineering, Gheorgheni, Romania, 23-26 April 2009, EMT Technical Review Special Edition, (2009) pp. 64-67.

[9] G. Bódai, S. Bisztray-Balku: Reciprocating elastomeric hydraulic seals’ tribology and leakage calculation, Proceedings of the Sixth Conference on Mechanical Engineering, G-2008-B-1, 29-30 May 2008, Budapest, Hungary

[10] G. Bódai, T. Goda: Analysis of the windscreen wiper on rotating glass cylinder test rig, Proceedings of the Seventh Conference on Mechanical Engineering, 29-30 May 2010, Budapest, Hungary

[11] G. Bódai, T. Goda: Mixed Friction Of Windscreen Wiper: Numerical Analysis, Proceedings of the Seventh Conference on Mechanical Engineering, 24-25 May 2012, Budapest, Hungary

[12] Bódai G., Váradi K., Bisztray-Balku S.: A tömítőnyomás végeselemes számítása és a résveszteségek meghatározása elasztomer dugattyúrúd tömítéseken (in Hungarian), GÉP, vol. 58, 2007/10-11, pp. 13-16.

[13] Bódai G., Goda T.: Ablaktörlő lapát kvázistatikus és dinamikai viselkedésének mérése és modellezése (in Hungarian), GÉP, vol. 59, 2008/10-11, pp. 3-6.

[14] Bódai G., Goda T.: Hiperelasztikus anyagok mechanikai viselkedésének elmélete és alkalmazása (in Hungarian), AGTEDU konferencia 2009, Kecskemét, 2009 november 5. pp. 155-160

[15] Bódai G., Váradi K., Molnár L., Pálfi L.: Polietilén gázcső elszorítás kísérleti és numerikus vizsgálata (in Hungarian), GÉP, vol. 60, 2009/10-11, pp. 14-17.

[16] Goda T., Bódai G.: O-gyűrű szivárgás számítása korszerű numerikus módszerrel, (in Hungarian), GÉP, vol. 60, 2009/10-11, pp. 43-46.

[17] Molnár L., Váradi K., Bódai G., Zwierczyk P.: Tűgörgős csapágyak egyszerűsített modellezése mérnöki szerkezetek végeselemes analíziséhez (in Hungarian), GÉP, vol. 61, 2010/9-10, pp. 55-58.

[18] Bódai G.:, Váradi K., Molnár L., Oroszváry L.: Fékhenger-membrán hőmérsékletfüggő állapotvizsgálata (in Hungarian), GÉP, vol. 61, 2010/9-10, pp. 111-114.

[19] L. Molnár, K. Váradi, G. Bódai, L. Oroszváry: Fékhenger-membrán numerikus állapotvizsgálata (in Hungarian), XIX Nemzetközi gépészeti találkozó OGÉT 2011. Csíksomlyó, 04.28-05.01, pp. 160-164.

[20] G. Bódai, T. Goda: Mixed Friction Of Windscreen Wiper: Numerical Analysis, Special PHD Proceedings of the Seventh Conference on Mechanical Engineering, 29-30 May 2012, Budapest, Hungary (accepted for special edition of the conference)

[21] G. Bódai, T. Goda: Measurements and FE calculations of windscreen wiper; examination of quasi-static and dynamic behavior, IV European Conference on Computational Mechanics (ECCM), 16-21 May 2010, Paris, France

[22] G. Bódai, K. Váradi, L. Molnár: Experimental and numerical examination of Brake Cylinder Membrane, Danubia-Adria-Symposium, Siófok, Sept. 28 - Oct 1, 2011

[23] G. Bódai, T. Goda: Relaxation master curve construction from constant strain-rate tensile tests, article submitted to Material Science Forum

[24] G. Bódai, K. Váradi, L. Molnár, L. Oroszváry: Thermal simulation of a pin on a rotating cylinder jacket system article submitted to Periodica Politechnica

[25] G. Bódai, T. Goda: Specimen level examination of windscreen wiper blade’s tribological behavior, manuscript under work

[26] G. Bódai, K. Váradi, L. Molnár, L. Oroszváry: Thermal simulation of a pin on a rotating cylinder jacket system Periodica Politechnica, (submitted)

[27] L. Molnár, K. Váradi, G. Bódai, L. Oroszváry: Fékhenger-membrán numerikus állapotvizsgálata (in Hungarian), XIX Nemzetközi gépészeti találkozó OGÉT 2011. Csíksomlyó, 04.28-05.01, pp. 160-164.

[28] G. Bódai, T. Goda: Measurements and FE calculations of windscreen wiper; examination of quasi-static and dynamic behavior, IV European Conference on Computational Mechanics (ECCM), 16-21 May 2010, Paris, France

[29] G. Bódai, K. Váradi, L. Molnár: Experimental and numerical examination of Brake Cylinder Membrane, Danubia-Adria-Symposium, Siófok, Sept. 28 - Oct 1, 2011

References

[1] A. Koenen, A. Sanon: Tribilogical and vibroacustic behaviour of a contact between rubber and glass (application to wiper blade), Trib. Int., Vol.40 (2007) pp.1484-1491

[2] F. Deleau, D. Mazuyer, A. Koenen: Sliding friction at elastomer/glass contact: Influence of the wetting conditions and instability analysis, Trib. Int., Vol.42 (2009) pp.149-159.

[3] B. N. J. Persson, M.Scaraggi: On the transition from boundary lubrication to hydrodynamic lubrication in soft contacts, J. Phys. Condens. Matter, Vol.21 (2009) pp.1-22.

[4] G. A. Holzapfel: Nonlinear Solid Mechanics: A Continuum Approach for Engineering, Wiley, 2000, ISBN 0471823198

[5] J. Bonet, R. D. Wood: Nonlinear Continuum Mechanics for Finite Element Method, Cambridge University Press, 2008, ISBN 978-0-511-39468-3

[6] B. N. J. Persson: On the theory of rubber friction, Surface Science Vol.401, (1998) pp.445–454