|

|

BMe Research Grant |

|

Géza Pattantyús-Ábrahám Doctoral School of Mechanical Engineering

Department of Polymer Engineering

Supervisor: Dr. Ferenc Ronkay

Morphological, mechanical and electrical properties of conductive polymer composites

Introducing the research area

Nowadays, it is more and more important to use “green energy”. The use of bioethanol and renewable resources for producing electricity, hot water and for heating is spreading more widely in the framework of sustainable development. Producing electricity by fuel cells is a very promising sector of environmentally responsible energy consumption. The cells produce electricity directly and the only by-products of the process are water and heat. One of the most important parts of the cells are mono- and bipolar plates. Traditionally, these plates were made of metal but the electrochemical stability of metals is not sufficient, therefore, researchers started using electrically conductive composites to replace metals.

Brief introduction of the research place

The research work is carried out at the BUTE Department of Polymer Engineering. The Department has an ISO 9001:2008 certificate; the laboratory and the instruments are accredited by the Hungarian Accreditation Board. The Department also issues a journal (eXPRESS Polymer Letters), which gained an impact factor of 2.294 in 2012.

History and context of the research

Electrically conductive polymer composite is a mixture of insulating polymer and electrically conductive fillers. These fillers can be metal based (e.g. copper) and carbon based (e.g. carbon black, graphite, carbon nanotubes, graphene).

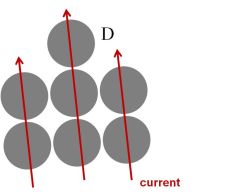

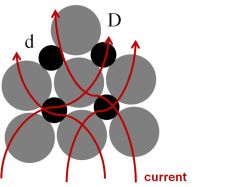

The conductivity of composites increases significantly when the fillers form a conductive network in the matrix, which usually amounts to 10-16 orders of magnitude increment, considering the approximately 10-14 S/cm conductivity of polymers. The conductivity of the composites is affected both by the type and quality of the materials used and the manufacturing process applied. In mono composites, the conductive network formed by the fillers contains only moderate amount of conductive routes and they are short, too. In hybrid composites, the smaller particle sized fillers can produce more complex and continuous conductive networks even at smaller amount of fillers and a higher conductivity can be reached. From practical point of view, the key parameter is the dispersion state of the fillers, as if significantly influences the mechanical and electrical properties of composites.

Conductive network of mono and hybrid composites

The research goal, open questions

The primary goal of my research is to develop various compositions of conductive polymer composites suitable for processing mono- and bipolar plates. Furthermore, I investigate the filler dispersion of the different matrix-filler systems and define the connection between the dispersion state and the mechanical and electrical properties to assist the selection of the proper materials, compositions and processing methods. Finally, I examine the temperature dependency of the electrical properties of composites, since the working temperature of these composites is often above ambient, in case of fuel cells at about 80-120°C.

Methods

Preparation of composites

Different plastics (polypropylene, poly(buthylene-terephtalate) and polycarbonate) and fillers (graphite, carbon black and multi-walled carbon nanotubes) were used to prepare the composites by melt mixing and compression and injection molding.

Investigation of filler dispersion

I developed a method suitable for characterizing the filler dispersion in the composites. The dispersion state of the nano-sized filler content was examined by scanning electron microscopy, whereas the dispersion of graphite was analyzed by optical microscopy. From the images of the polished cross sections, graphite agglomerates were detected then their average area and the distance between the neighboring agglomerates was determined to characterize the dispersion state of graphite in the matrix.

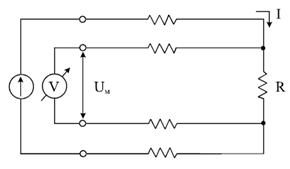

Electrical measurements

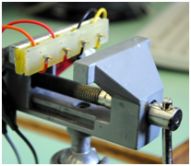

The electrical conductivity of composites was investigated by a high precision method called four point probe method. A special head was prepared for this measurement, four gold-plated Ingun probes were embedded in a distance of 2 cm from each other in an insulator plate.

Conceptual sketch of the four point probe method and the probe

Improvement of the above test method allowed accurate measurement of the conductivity of composites at varied ambient temperature, too.

Mechanical measurements

The strength, impact strength and stiffness of composites are all very important parameters in terms of practical use. As these properties are highly affected by the filler dispersion state in the composites, I also performed Charpy impact strength tests and bending tests, then analyzed the connection between these results and filler dispersion.

Results

Material development

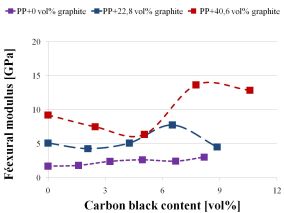

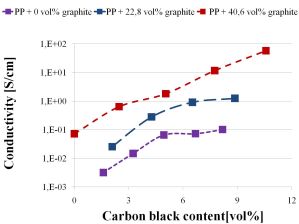

I prepared more than 100 different material compositions and examined their structural, electrical and mechanical properties. The results proved that the conductivity of hybrid composites was higher than those with only one type of filler. The higher flexural strength of hybrid composites is attributable to the better filler dispersion – since graphite, carbon black and carbon nanotubes help disperse each other more uniformly resulting in an extended conductive network and strengthening effect. I found that there is connection between the average area of the graphite agglomerates and the stiffness of composites; the higher the average area of the graphite agglomerates the higher the flexural modulus.

Hybrid-filled composites kept their good electrical properties even at higher temperatures. The conductivity of hybrid-filled composites containing polypropylene or poly(buthylene-terephtalate) as matrix did not change significantly until 130°C, whereas this limit was found at 160°C for those containing polycarbonate. This is advantageous in practice, since composites containing higher amount of filler, consequently showing higher conductivity and higher rigidity are capable of maintaining their excellent electrical properties even at higher temperatures. Great amount of fillers prevents composites from heat expansion and hinders the breaking of conducting paths in the composites.

Flexural modulus, graphite dispersion and conductivity of hybrid-filled conductive polypropylene composites

Development of processing technology

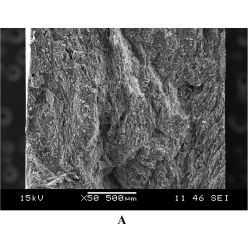

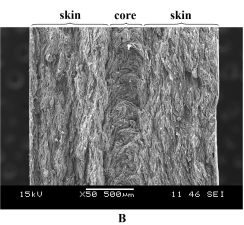

I found that the conductivity of injection molded specimens was 1-2 orders of magnitude lower than that of the compression molded ones. Investigation of the structure of differently processed composites explored the reason for differences. In the case of compression molded specimens, a homogeneous structure was formed which increases conductivity. Contrary to this, in the case of injection molded specimens, a skin-sore structure was formed lowering conductivity. The conductivity of the composite results from the conductivity of the skin and the core. Graphite particles in the skin are oriented, resulting in lower conductivity decreasing the total conductivity of the composite despite the higher conductivity value of the core with non oriented graphite particles.

Scanning electron microscopy images of cross sections of compression (A) and injection molded (B) plates

Utilization in practice

We prepared compression molded mono- and bipolar plates from the developed materials then assembled prototype fuel cells with the help of an industrial partner. Our research activity and results were even reported on the Hungarian scientific program, Delta, a produce of MTVA.

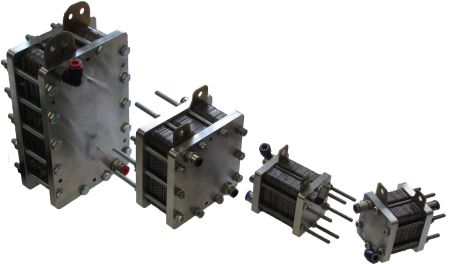

Various power output (30-120 W) fuel cells

Expected impact and further research

Our studies demonstrated that the developed material compositions have advantageous electrical properties and they maintain these properties even at higher temperatures, which renders them candidates for making fuel cells. Furthermore, we would like to contribute that the economical mass production of fuel cells be implemented in Hungary among the first in the world.

Publications, references, links

Publications

1. Király A., Ronkay F.: Szénalapú töltőanyagokat tartalmazó PP bipoláris lemezek üzemanyagcellákhoz: kompromisszum a vezetőképesség és a feldolgozhatóság között (in Hungarian), Műanyagipari Szemle, 3, 75-84, 2011.

2. Király A., Ronkay F.: Hibridtöltésű vezetőképes műanyagok fejlesztése (in Hungarian), Műanyag és Gumi, 48, 441-444, 2011.

3. Király A., Ronkay F.: Vezetőképes polimerek fejlesztése (poster presentation, in Hungarian), VIII. Országos Anyagtudományi Konferencia, Balatonkenese, Hungary, 2011.10.9-11.

4. Király A., Ronkay F.: Üzemanyagcella PET palackokkal - Műanyaghulladékból zöld energia (in Hungarian), Élet és Tudomány, 44, 45-47, 2012.

5. A. Király, F. Ronkay: Properties of polymer composites containing hybrid fillers. Gépészet 2012: Proceedings of the eighth international conference on mechanical engineering. Budapest, 2012.05.22-25. 228-233. ISBN: 978-963-313-055-1

6. A. Király, F. Ronkay: Properties of polymer composites containing hybrid fillers (presentation), Gépészet 2012, Budapest, 2012.05.22-25.

7. Király A., Ronkay F.: Üzemanyagcellák bipoláris lemezének gyártástechnológia-fejlesztése (in Hungarian), Műanyag és Gumi, 49, 432-435, 2012.

8. Király A., Ronkay F.: Tüzelőanyag-cellák bipoláris lemezének anyag- és gyártástechnológia fejlesztése (presentation), Mechanoplast Conference, 2013.04.19-20.

9. Király A., Ronkay F.: Tüzelőanyag-cellák bipoláris lemezének anyag- és gyártástechnológia-fejlesztése (in Hungarian), Mechanoplast 3013. Miskolc, Hungary, 3013.04.19-20. 1-6. ISBN: 978-963-358-033-2.

10. A. Király, F. Ronkay: Development of electrically conductive polymers, Materials Science Forum, 729, 397-402, 2013.

11. A. Király, F. Ronkay: Developing bipolar plates for fuel cells, Plastics Research Online, 1-3, 2013. (DOI: 10.2417/spepro.004938)

12. A. Király, F. Ronkay: Effect of graphite and carbon black fillers on the processability, electrical conductivity and mechanical properties of polypropylene-based bipolar plates, Polymers and Polymer Composites, 21, 93-100, 2013. (IF: 0,31)

13. A. Király, F. Ronkay: Effect of filler dispersion on the electrical conductivity and mechanical properties of carbon/polypropylene composites, Polymer Composites, 34, 1195-1203, 2013. (IF: 1,48)

14. A. Király, F. Ronkay: Effect of processing technology on the morphological, mechanical and electrical properties of conductive polymer composites Journal of Polymer Engineering, 33, 691-699, 2013. (IF:0,28)

15. A. Király, F. Ronkay: The influence of nano-sized filler content on the mechanical and electrical properties of hybrid filled conductive polymer composites (előadás), 3rd International conference on Nanomechanics and Nanocomposites, Hong Kong, China, 2014.05.22-25.

References

[1] Blythe T., Bloor D.: Electrical properties of polymers. Cambridge University Press, New York (2005).

[2] Antunes R. A., de Oliveira M. C. L., Ett G., Ett V.: Carbon materials in composite bipolar plates for polymer electrolyte membrane fuel cells: A review of the main challenges to improve electrical performance. Journal of Power Sources, 196, 2945-2961 (2011).

[3] Dweiri R., Sahari J.: Electrical properties of carbon-based polypropylene composites for bipolar plates in polymer electrolyte membrane fuel cells (PEMFC). Journal of Power Sources, 171, 424-432 (2007).

[4] Planes E., Flandin L., Abberola N.: Polymer composites bipolar plates for PEMFCs. Energy Procedia, 20, 311-323 (2012).

[5] Mighri F., Huneault M. A., Champagne M. F.: Electrically conductive thermoplastic blend for injection and compression molding of bipolar plates in the fuel cell application. Polymer Engineering and Science, 44, 1755-1765 (2004).