|

|

BMe Research Grant |

|

Doctoral School of Electrical Engineering

Department of Electron Devices

Supervisor: Dr. Mizsei János

Investigation and Modeling of the Temperature Dependence and Thermal Behavior of Photovoltaic Devices

Introduction of the research area

The temperature dependence and thermal behavior of photovoltaic devices is a well-known phenomenon amongst experts. In practical applications they are considered to a certain degree, but the theoretical bases and the deeper understanding of the phenomena, and the effects of the technological parameters on temperature dependence, as well as design and optimization aspects are a quite neglected field. My research goals include approaching the temperature dependence and the thermal behavior of solar cells as parameters that can be designed and influenced and also determining the factors that influence temperature dependence. Further research targets are the investigation of the thermal behavior of solar cells and giving theoretical explanations for the measured phenomena as well as incorporating the research results in precise electro-thermal models.

Brief introduction of the research place

The research work is carried out at the Semiconductor Laboratory of the Department of Electron Devices. The clean room established in 2012 allows a variety of basic semiconductor processing steps, thus experimental solar cell structures or semiconductor sensors or even simpler micro- and nanoelectronics devices can be fabricated. Our department is also internationally recognized for the thermal characterization of electronic devices.

History and context of the research

Like any semiconductor device photovoltaic devices show a significant temperature dependence. This temperature dependence is mostly taken under consideration in applications, but manufacturers and designers are inclined to consider temperature dependence as an unavoidable negative feature of the device than a characteristic that can be influenced and optimized. Some simple theoretical descriptions of the temperature dependent behavior of solar cells can be found at textbook level, but they merely demonstrate the effects; the temperature coefficients used for practical applications are mainly determined by measurements on completed devices, without being aware of the thermal design possibilities.

To provide a design approach and optimization technique to the temperature dependence and the thermal behavior of solar cells, two basic criteria have to be fulfilled. Firstly, a paradigm shift is required to consider temperature dependence as a design parameter, and also an extensive research is needed on the influence of material and technological parameters including the structure of the solar cells on the temperature dependence and the thermal behavior. Research also has to provide theoretically justified explanations to the measured phenomenon, to ensure a deep understanding and transferability of the results.

Nowadays, solar cell manufacturers tend to reduce the thickness of solar cells (Figure 1) to save feedstock. In addition, the demand for chip-integrated photovoltaic power supplies and photosensors is expanding. In these devices the photoactive layer thickness is very thin due to technological circumstances. Thus the question arises on how the thickness of the photoactive layer influences the temperature dependence of the device.

Figure 1: Predicted solar cell wafer thicknesses in the near future (ITRPV road-map 2014)

Aim of the research

On the longer term, the goal of my research is to give a deep understanding of the factors that influence the temperature dependence of photovoltaic devices and of the thermal behavior of solar cells, supporting the results with theoretical explanations and practical models.

In addition, I hope that my research will contribute to spreading the approach that the temperature dependence and the thermal behavior are not unavoidable negative features, but a parameters that can be influenced and optimized by design. This change in basic views could help in the development of photovoltaic devices with better operating characteristics.

Regarding shorter term results, my research work represents two main directions. The first one relates to the trend of incorporating ever thinner photoactive layers into photovoltaic devices. This raises a crucial question, whether or not the photoactive layer thickness influences temperature dependence and hence, practical usability, and how – if the answer is yes. This was investigated thoroughly by systematic measurements and modeling on solar cell samples specially designed and processed for this purpose. Another important technological parameter investigated the same way is the series resistance of the devices.

The other focus area of my research was the investigation and modeling of the thermal behavior of solar modules. Solar cells convert approximately 20 % of the incident light into electrical energy, the rest is heat that warms up the module. Therefore, it is essential to ensure an efficient heat extraction from the module. With the investigation and modeling of the heating process valuable information can be gained on both the static and dynamic or transient thermal behavior. This information enables the specific thermal optimization of solar modules and the creation of precise operation models.

Figure 2: Typical structure of a solar cell

Methodology

Influence of photoactive layer thickness on temperature dependence

The effect of photoactive layer thickness on temperature dependence was investigated with specially fabricated samples that only differed in the thickness of the photoactive layer (Figure 3). For the fabrications of these samples a special fabrication process was developed. Main aspect of the process is to manufacture all samples on the same wafer simultaneously. Thus the technological and wafer-to-wafer variations can be eliminated. The samples were processed in the clean room facilities of our department and their I-V characteristics and spectral response were measured at different temperatures and light intensities. From these measurements the characteristic parameters of a solar cell and their temperature dependence can be derived. For evaluation a five-parameter, single diode model based on the Lambert-W function was chosen. By deriving the temperature dependence of the model parameters and completing them with the results of the temperature dependent spectral response measurement results a theoretical explanation can be given to the phenomena. If the temperature dependence of these parameters is known, semi-empirical models can be derived that precisely describe the operation of the solar cells at different temperatures.

Figure 3. Sample preparation process developed for testing the impact of photoactive layer thickness

Thermal transient testing of solar cells

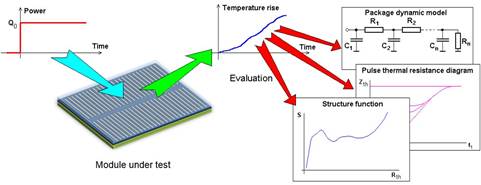

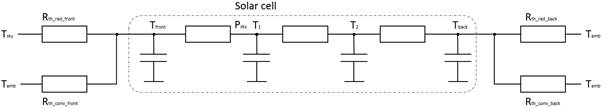

The most important factor for the investigation of the thermal behavior of encapsulated solar cells (solar panels or modules) is to be able to analyze the heat path between the place of the heat generation (mostly the p-n junction) and the environment. This practically includes all heat resistances and heat capacitances that the heat has to overcome while escaping to the environment. Thermal transient testing (Figure 4) – a well-established method for the measurement of the heat capacitance and heat resistance of packages of electronic devices – can be adopted to the investigation of photovoltaic devices. In case of electronic devices the measurement is already standardized, but in the case of photovoltaic devices one can encounter difficulties due to the different structure. Light sensitivity and different encapsulation materials are the concerns that can be overcome easily, but the different size and largely different power density represent serious issues. Since conventional electronic devices feature small size and large power density, in these devices heat radiation is a negligable factor. In case of solar modules the surface is high and the power density is lower by orders of magnitude, and a significant portion of the heat is extracted by radiation and convection. Thus solar modules need to be measured in a DCP (dual cold plate) measurement arrangement, and finding the optimal measurement parameters is more challenging, too.

From the results of properly performed thermal transient measurements the so called structure function can be calculated. From this representation of the one dimensional heat path the thermal resistances and capacitances can be extracted. Knowing these parameters we can create the thermal RC-ladder that describes the static and dynamic thermal behavior. The structure function also contains information on the layer structure and thus can be helpful in the analysis and optimization of photovoltaic device structures.

Figure 4: Thermal transient testing on solar cells

Results

Influence of the photoactive layer thickness on temperature dependence

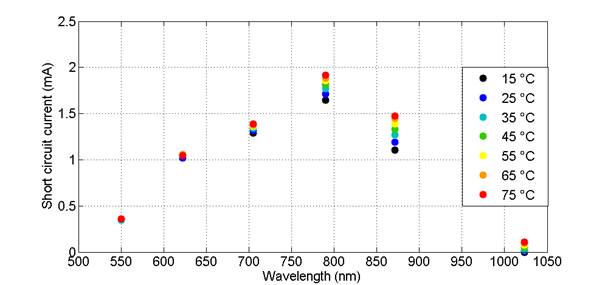

The investigation of the experimental samples clearly showed that the thickness of the photoactive layer influences the temperature dependence of the cell. The photoactive layer thickness influences mainly the temperature dependence of current; the temperature dependence of voltage is practically unaffected. Since the temperature dependence of voltage is by one order of magnitude higher than that of the current, a change in photoactive layer thickness causes only minor variations in the temperature dependence of the solar cell’s energy production and efficiency, but in general, thinner photoactive layer or solar cells tend to increase temperature dependence. Although this suggests that the development trend of thinning the photovoltaic layers will not have significant impact on energy harvesting, still the effect has to be taken into account for the precise modeling of devices. The increased temperature dependence of current can be explained by the temperature dependence of the absorption factor of silicon. Since the absorption factor is also wavelength dependent, the absorption depth is different for every wavelength. For very thin cells, only the near-UV region will absorb light entirely, longer wavelengths get absorbed only partially, but the absorbed fraction will increase as temperature rises – considering the increase of absorption factor with temperature –, resulting in an increase of the photo-generated charge carriers, which increases photo current. The thicker a solar cell the wider the wavelength range of full absorption will be, thus the impact of excess photo generation (with increasing temperature) is smaller, since the semiconductor has already absorbed the majority of light at lower temperatures. This theory is supported by the temperature dependent spectral response measurements, showing that the highest temperature dependence appears in the near-IR region (Figure 5), and with decreasing photoactive layer thickness the temperature dependence increases also at lower wavelengths.

Figure 5: Spectral response of a solar cell as a function of temperature

Effect of the series resistance on temperature dependence

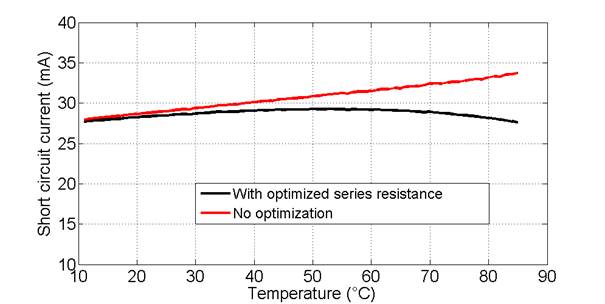

Although the decrease in photoactive layer thickness will not cause serious issues in energy production parameters, increasing temperature dependence can cause higher uncertainties in PV-based light sensors, where short circuit current is generally measured for characterization. In my research, I showed that the temperature dependence of short circuit current decreases with increasing the series resistance. Therefore, the photoactive layer thinness related increase in temperature dependence can be compensated or at least minimized by optimally chosen series resistance (Figure 6).

Figure 6: Temperature dependences of the short circuit current of sensors with optimized and not optimized series resistances

Adaptation of thermal transient testing to solar cells

The successful adaptation of the thermal transient measurement technique to solar cells in itself is constitutes an achievement, since the reliable and proper measurement of solar cells required several modifications to the standard measurement technique. The parameters needed for the thermal RC-ladder based thermal models were provided from thermal transient testing (Figure 7). From the measurement results then the components characterizing the convection and thermal radiation of the solar cell structure can be derived (Figure 8). From these results, thermal radiation can be extracted as a temperature dependent thermal resistance. As this parameter could only be calculated with difficulties with purely theoretical approaches, possibility of gaining thermal radiation properties from measured data significantly eases the thermal modeling of solar modules.

Figure 7: RC-ladder based thermal model of a solar module

Figure 8: Structure functions with different measurement conditions, showing the different components of the heat extraction from a solar cell

Modeling

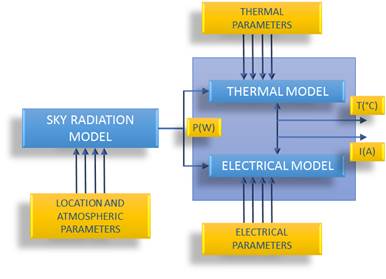

Based on the single-diode solar cell model, a new semi-empirical electric model was developed that gives a precise description of temperature dependent operation using only a few temperature coefficients. Complementing this with a thermal RC-ladder based thermal model a combined electro-thermal model was developed. Compared to current models this model has the advantage of giving a precise operational description of the solar cell without the need of a temperature feedback.

Figure 9: Combined electro-thermal model developed in the research

Expected impact and further research

The results of my research were published on renown conferences (Therminic, EUPVSEC, SEMITHERM, DTIP), and the latest results are published continuously in scientific journals. My research contributes to the OTKA project no. 100794 that targets development of novel modeling, characterization and measurement techniques for solar cells. Based on the results of this project and my research on the temperature dependence of solar cells we submitted the project proposal no. 116848 to the Hungarian Scientific and Research Fund (OTKA). This project targets the combined electro-thermal optimization possibilities of solar cells and modules and is under evaluation. The project GOP-1.1.1-11-2012-0289 that targets the development of energy forecast models for renewable energy sources directly applies the models developed in my research (Figure 10). Under my supervision several BSc. and MSc. theses were written in the field, as well as price winning contributions to the institutional and national Scientific Student’s Conference.

Publications, references, links

List of related own publications

1. Balázs Plesz, András Vass-Várnai

Characterization of solar cells by thermal transient testing

MICROELECTRONICS JOURNAL 45:(12) pp. 1710-1715. (2014)

2. B. Plesz, S. Ress, P. G. Szabó, G. Hantos, D. Dudola

Issues of Thermal Transient Testing on Photovoltaic Modules

In: Chris Bailey, Marta Rencz, Bernhard Wunderle (Ed.)

Proceedings of

the 20th International Workshop on THERMal INvestigation of ICs and

Systems

(THERMINIC'14).

3. B. Plesz, S. Ress

Investigation of the thermal behavior of thin crystalline silicon solar cells

In: P E Raad, M Rencz, B Wunderle, A Poppe (Ed.)

Proceedings of

the 19th International Workshop on THERMal INvestigation of ICs and

Systems:

THERMINIC 2013.

4. B. Plesz, Á. Földváry

Thermal Behavior of c-Si Solar Cells with thin photoactive layers

In: Proceedings of the 6th International Workshop on Teaching in Photovoltaics (2012).

5. A Vass-Várnai, B Plesz, Z Sárkány, A Malek, M Rencz

Application of Thermal Transient Testing for Solar Cell Characterization

In: Paul Wesling, Kathe Ericson (Ed.)

Proceedings

of the 28th IEEE Semiconductor Thermal Measurement and Management

Symposium (SEMI-THERM'12). 360 p.

6. B Plesz, E Bándy, A Földváry

Low cost solar irradiation sensor and its thermal behavior

MICROELECTRONICS JOURNAL 42:(5) pp. 594-600. (2011)

7. B. Plesz

Thermal Behavior of Crystalline Thin Film Silicon Solar Cells

In: IEEE (Ed.)

Proceedings of

the 17th International Workshop on THERMal INvestigation of ICs and

Systems

(THERMINIC'11)

8. B Plesz, Gy Horváth, A Vass-Várnai

Characterization of solar cells by thermal transient testing

In: IEEE (Ed.)

Proceedings of

the 17th International Workshop on THERMal INvestigation of ICs and

Systems

(THERMINIC'11)

9. B Plesz, E Bándy, Á Földváry, V Timár-Horváth, J Mizsei

Thermal Behavior of Thin Photoactive Layer Crystalline Solar Cells

In: Bernard Courtois, Jean Michel Karam, Ryutaro Maeda, Pascal Nouet, Peter Schneider,

Hsiharng Yang (Ed.)

Collection of

Papers Presented at the Symposium on Design, Test, Integration and

Packaging

of MEMS/MOEMS (DTIP'10). 415 p.

10. Bándy Enikő, Földváry Árpád, Plesz Balázs

Thermal Issues of Solar Irradiation Sensor

In: anon (Ed.)

Proceedings of

the 15th International Workshop on THERMal INvestigations of ICs and

Systems

Links