|

|

BMe Research Grant |

|

George A. Olah Doctoral School of Chemistry and Chemical Technology

BME VBK, Department of Organic Chemistry and Technology

Supervisor: Dr. Bordácsné Bocz katalin

Development of light-weight environmentally friendly PLA composite systems and flame retardancy thereof

Introducing the research area

In my doctoral work, the production, testing and application-oriented development of light-weight (bio)polymer composite systems was carried out. The topicality of the research is given by the fact that reducing the weight of products, thus the amount of raw materials used, is one of the most obvious directions of development towards the sustainability of many industries. When creating composites, the advantageous properties of different raw materials are combined, and high value-added products can be produced by the appropriate choice of composition and structure. Both self-reinforced composites (SRCs) [1] and polymer foams [2] meet these criteria, so the aim of my research was to improve the functional characteristics of such heterogeneous systems, to further develop their manufacturing technology, and to characterize them extensively.

Brief introduction of the research place

My research was conducted at the Department of Organic Chemistry and Technology, BUTE, under the supervision of Dr. Katalin Bocz and Dr. György Marosi. Our research group maintains a productive partnership with the Department of Polymer Engineering of BUTE, hence I was able to contribute to the success of several joint scientific works and industrial projects (GINOP-2.1.1-15-2016-01063, NVKP_16-1-2016-0012, 2018-1.3.1-VKE-2018-00017).

History and context of the research

As society and decision-makers are becoming more environmentally conscious, the technical terms of sustainable development and circular economy are becoming more and more ingrained in common parlance as increasingly fashionable terms. Fortunately, research has already been going on for decades by academia and market players to develop raw materials and manufacturing methods with low environmental impact and high efficiency. Inexpensive, easily manufactured, durable polymers and their composites increase the standard of living of humanity and reduce energy consumption year by year, thanks in part to their key role in food safety, transportation & logistics, automotive, and construction industries [3,4,5,2].

To facilitate recycling, SRCs are being developed in which the reinforcing fibers and the matrix material are made of the same polymer [1]. Thus, they are much lighter than conventional composites (reinforced with glass, basalt or carbon fiber) and can be fully recycled, as there is no need to separate the reinforcing fibers from the matrix. Light-weight products can also be achieved by foaming the polymeric base material, in which case up to 90-97% of the product consists of air-filled pores. Polymer foams, as thermal insulation, save more than 140 times the energy needed for their production, and as packaging, they can effectively protect products that are several orders of magnitude more valuable from physical impacts.

Sadly, the advantageous properties of plastics (cheap, easy to produce, durable, lightweight) also lend to its potential to cause serious environmental damage. Infamous examples of this are the five ocean garbage patches, 96.5% of which are the result of problematic (or non-existent) waste management practices in low-income countries outside North America and Europe [6]. Although this is primarily a waste treatment issue, there has also been an increasing focus on biodegradable polymers over the past decade. Of these, polylactic acid (PLA) is produced in the largest quantities, which is also produced from renewable sources.

The research goals, open questions

The aim of my research was to develop composite systems that, due to their lower density, could offer an environmentally friendly alternative for product designers in the future, thus providing the opportunity to replace the solutions and raw materials currently in use.

My goal was to effectuate the value-adding modification of PLA, which is an intensively researched, promising raw material with properties similar to polyethylene terephthalate (PET). Besides its high tensile strength and modulus, nevertheless, it is characterized by low elongation at break and poor impact resistance, so it is essential to improve these properties. The relatively low melt strength and slow crystallization of PLA have a negative effect on the foamability, so these characteristics also need to be corrected. In addition, foamed PLA is even more flammable than the raw material, so a suitable flame retardant (FR) additive system is required to produce a safe product. Since, according to the literature, flame retardant PLA foams have not yet been produced by continuous technology (e.g. extrusion), the way of implementation abounds in open questions.

It is important to consider the raw material of the end-of-life product as a valuable resource; therefore, the recycling of biopolymer products is also an issue to be addressed. In the production of SRCs, design for recycling is already taken into account; in the case of PLA the main challenge is to prevent hydrolytic degradation during the series of hot processing steps (extrusion, injection molding). Since the reinforcing and matrix materials of SRCs are made of similar (or identical) polymers, the difference between their melting temperatures (Tm) (so-called processing window) is also small. Accordingly, the manufacturing parameters must be adjusted to ensure proper fiber-matrix adhesion without damages to the fibers. In some cases, the processing window can only be increased by crystallization of the fibers, so the crystal structure formed during the production and recrystallization of PLA fibers has a major influence on the properties of the final product.

Methods

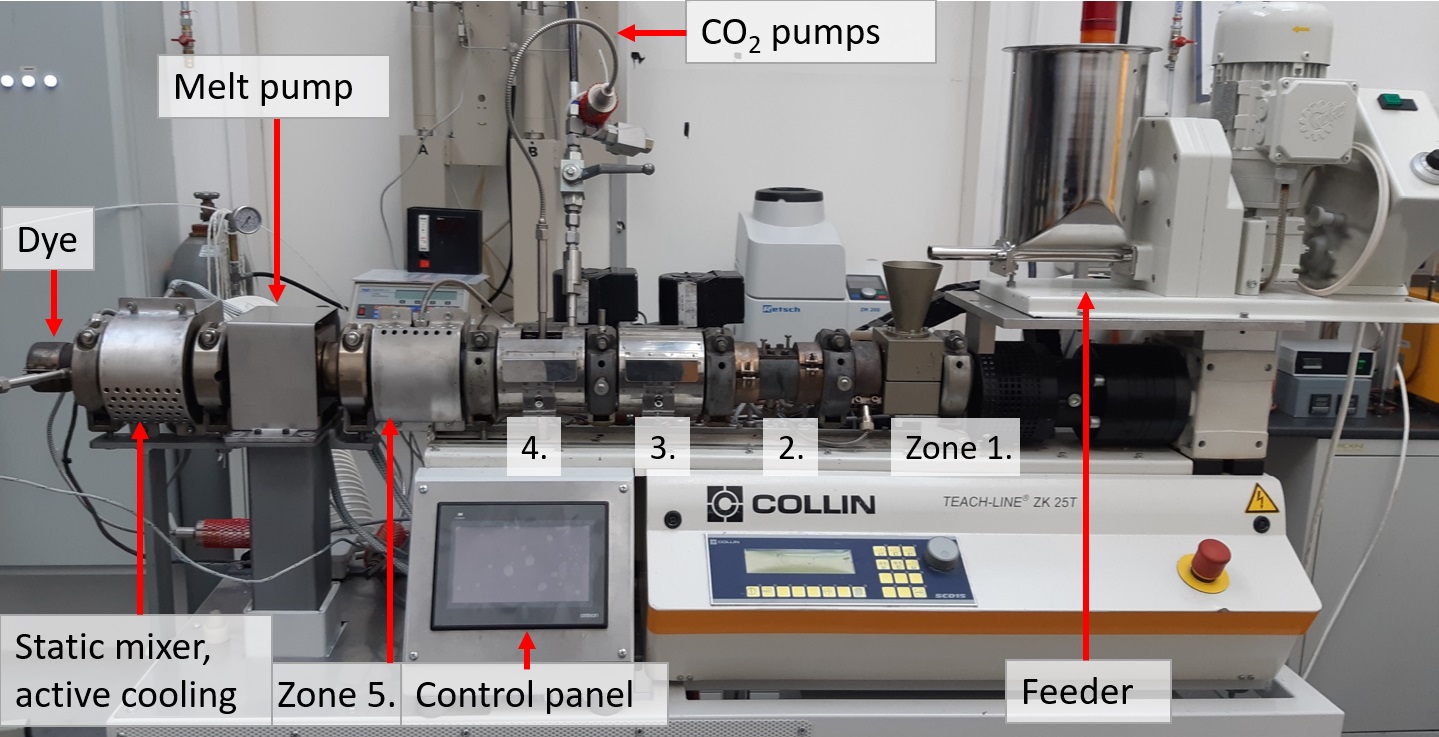

The foaming of the PLA was realized by supercritical CO2-assisted extrusion, a continuous production technology. Natural fiber-reinforced PLA foams were made on a single-screw extruder, while flame-retardant foams were made on a twin-screw extruder (Fig. 1). To the PLA base polymer, an epoxy-functionalized chain extender was premixed to increase molecular weight and melt strength, and talc or montmorillonite nucleating agent was added to accelerate crystallization kinetics. The extrusion foaming was performed with a decreasing temperature profile, 9 m/m% CO2 foaming agent was introduced into the melt using syringe pumps. The CO2 enters the supercritical state above 31 °C and 74 bar, and since both conditions are met inside the extruder, the blowing agent dissolves extremely well in the PLA melt, and acts like a plasticizer (reducing secondary interactions between the macromolecular chains). Thus, the mixture can be cooled well below the melting temperature of the PLA, thereby helping the foam structure exiting the die to stabilize. The manufactured foams were extensively characterized using a rotary rheometer, density measurement, differential scanning calorimetry (DSC), scanning electron microscopy (SEM) and compression tests. The thermal properties were examined by thermogravimetric analysis (TGA), pyrolysis combustion flow calorimetry (PCFC), limiting oxygen index and UL-94 tests.

Figure 1: Modified Collin Teach-Line ZK 25T foaming extruder

The production of PLA fibers used as a raw material for SRCs was carried out by two production methods, melt-blowing and high-speed electrospinning (HSES). The main difference between the two methods is that while the former is a solvent-free process, where the polymer is melted into fibers at 190 °C, the latter is a room temperature processing technology, so the chance of degradation is lower. Three types of PLA with different optical purities were used to manufacture fibres via melt-blowing, and then they were recrystallized at 85 °C. Self-reinforced PLA composites were produced from the purest PLA type using hot compaction process (165 °C, 60 bar, and 10-60 s). Composites and heat-treated fibers were characterized by DSC, SEM and tensile tests.

The effect of post-crystallization methods on the fiber properties produced with HSES were investigated; here only the purest PLA type was used, which is the most suitable for recrystallization. In addition to the previous methods, the crystalline structure of the samples were examined by X-ray diffraction, Raman spectroscopy, localized thermomechanical analysis (LTMA) and temperature-modulated DSC (MDSC).

Results

Natural fiber-reinforced polylactic acid (PLA) foams were prepared by supercritical carbon dioxide-assisted extrusion foaming. The addition of 5% cellulose or basalt fibre provided a wider processing window during foaming compared to the fiber-free material. As a result, the crystallinity of the product prepared at lower temperatures increased by 2 to 3 percentage points, while the weaker fiber matrix interaction resulted in cell fusion and a wider cell size distribution [S1].

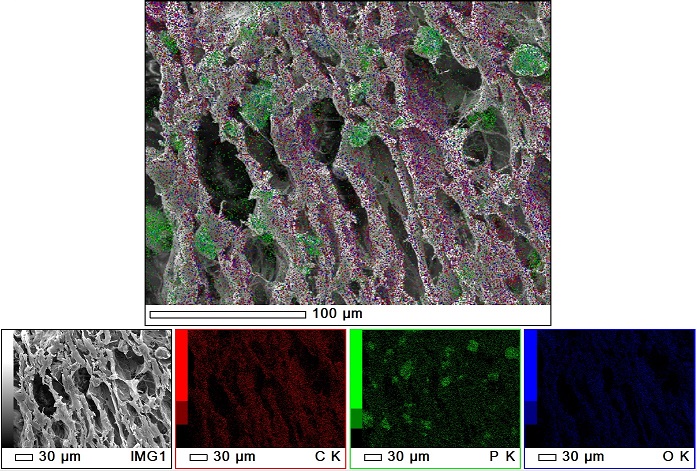

Figure 2: Distribution of flame retardant particles in the cellular structure of a PLA foam, SEM-EDS elemental mapping (red: carbon, green: phosphorus, blue: oxygen)

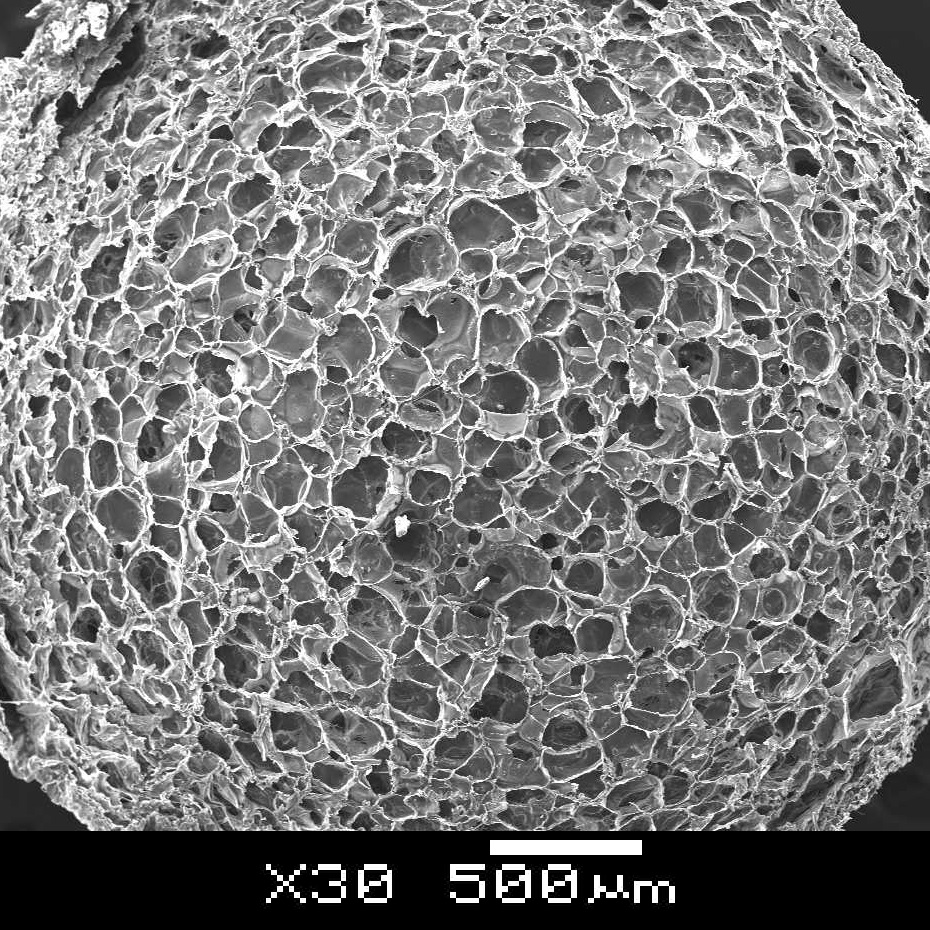

Low-density (ρ <0.05 g/cm3) microcellular PLA foams were firstly produced in flame retardant form using continuous technology. Under the conditions of extrusion foaming, the carbon dioxide (CO2) physical blowing agent is in supercritical state, thus effectively plasticized the PLA raw material. Using this method, PLA can be processed at 100-110 °C instead of the usual 170-190 °C. Foamability was improved by the addition of reactive chain-extender and nanosized clay mineral particles, and also a new intumescent flame retardant additive system, including cellulose treated with phosphorus and boron-containing compounds was developed to reduce flammability (Fig. 2). In spite of the fact that foams are more flammable than their solid polymeric counterparts (flame spread rates: 313 vs. 33 mm/min), significant flame retardancy was achieved. 40% reduction in specific peak of heat release rate, UL94 V-0 (i.e. self-extinguishing, Fig. 3) rating accompanied with limiting oxygen index value as high as 31.5 vol% were reached for the flame-retardant containing PLA foam [S2].

Figure 3: Horizontal UL-94 test of reference and flame retardant PLA foam

During the project implemented in the consortium of BME, DS Smith Packaging Hungary Kft. and Polifoam Műanyagfeldolgozó Kft, a PLA cushioning material with extremely low density and outstanding compressive strength (111 ± 20 kPa) was developed. Due to the good mechanical properties of the foam, it showed better energy absorption in the standard drop test (Fig. 4) than the polystyrene cushioning material widely used in the industry.

Figure 4: Drop tests of PLA cushioning foam, with accelerometer

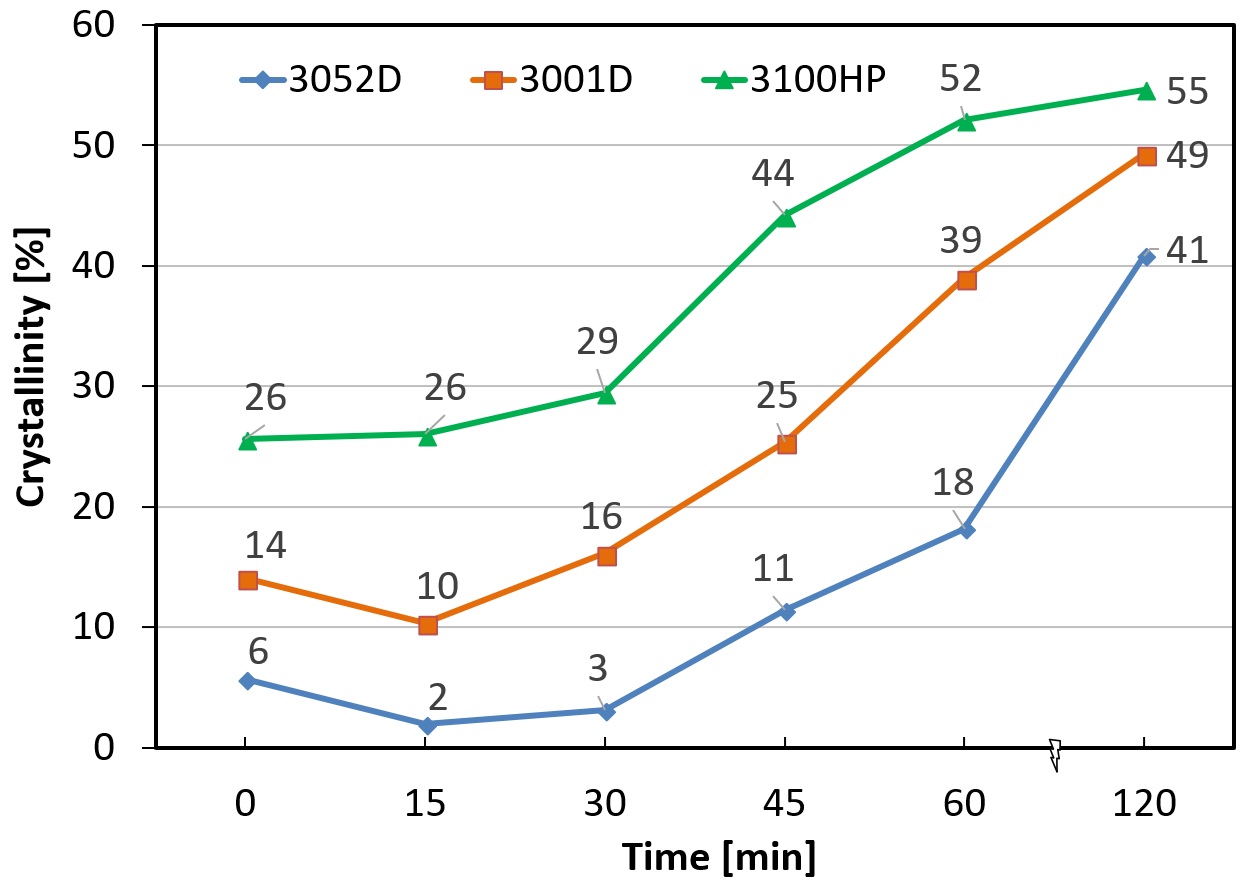

PLA fibers with a diameter of 2-14 µm were produced by melt-blowing from which self-reinforced composites were created for the first time. This environmentally friendly, solvent-free fiber manufacturing technology allowed the production of nonwoven webs, which were recrystallized to improve processability. Composites were prepared from PLA microfibers with 2–7 times higher (Fig. 5) crystalline proportions (compared to the original webs) by hot compaction method with a tensile strength 47% higher compared to self-reinforced composites made without post-crystallization [S3].

Figure 5: Increasing crystalline fraction of three different PLA grades as a function of recrystallization time

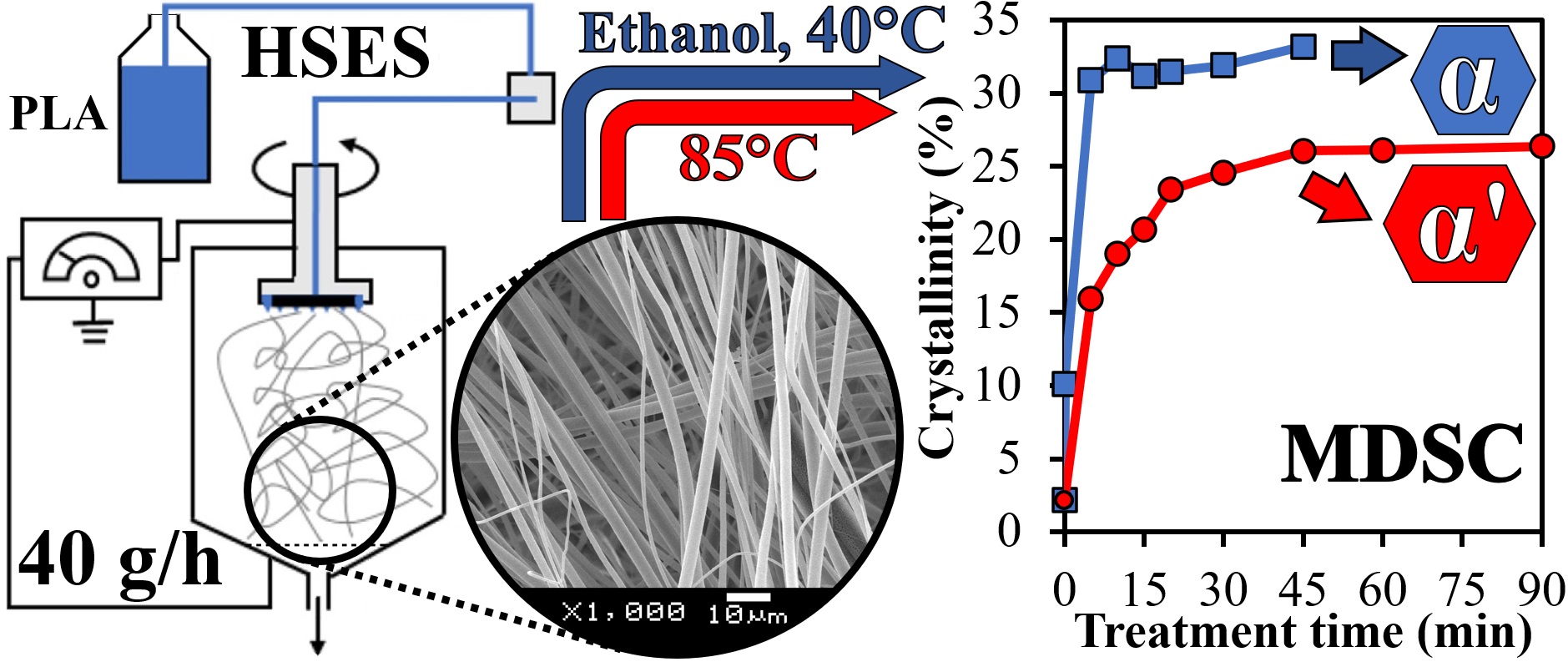

High-speed electrospinning (HSES) was used to produce PLA microfibers with a productivity of 40 g/h, uniquely in the literature. The recrystallization methods of PLA webs produced by the HSES technique were investigated, with regard to the morphology, crystal structure and mechanical properties of the final product. It was shown that while heat treatment results in the formation of the less stable α′ crystal modification, using ethanol treatment facilitates the formation of a more stable α modification. In terms of efficiency of the treatment methods, ethanol-assisted recrystallization proved to be better, the crystallinity of the modified webs exceeded 32%, and this was achieved 2-3 times faster than the 26% maximum crystallinity attained by the conventional heat treatment (Fig. 6). Also, a new formula was proposed and applied for the calculation of the crystalline fraction, which, in contrast to what has been used so far, provides more accurate enthalpy values for temperature-modulated differential scanning calorimetry (MDSC) [S5].

Figure 6: Recrystallization methods of PLA fibers prepared by high-speed electrospinning

Expected impact and further research

The citation and read indicators of the published research topics suggest that the topic is of interest and its industrial and scientific relevance is significant. The porotypes and production technologies implemented during the successful cooperation with industrial partners reinforce the importance of the field. Research into the widespread use of the versatile PLA foams and the in-line monitoring of the physical foaming via NIR spectroscopy (with industry 4.0 approach) is currently ongoing. A patent is also being filed on the subject to utilize the new discoveries and the experience gained during this research.

Publications, references, links

List of corresponding own publications.

S1 K. Bocz, T. Tábi, D. Vadas, M. Sauceau, J. Fages, G. Marosi: Characterisation of natural fibre reinforced PLA foams prepared by supercritical CO2 assisted extrusion. Express Polymer Letters, 10(9), 771–779. (2016) IF = 2.983 https://doi.org/10.3144/expresspolymlett.2016.71

S2 D. Vadas, T. Igricz, G. Marosi, K. Bocz: Flame retardancy of microcellular poly(lactic acid) foams prepared by supercritical CO2-assisted extrusion. Polymer Degradation and Stability, 153, 100–108. (2018) IF = 3.193 https://doi.org/10.1016/j.polymdegradstab.2018.04.021

S3 D. Vadas, D. Kmetykó, G. Marosi, K. Bocz: Application of Melt-Blown Poly(Lactic Acid) Fibres in Self-Reinforced Composites. Polymers, 10(7), 766. (2018) IF = 2.935 https://doi.org/10.3390/polym10070766

S4 D. Vadas, Á. Kmetty, T. Bárány, G. Marosi, K. Bocz: Flame retarded self-reinforced polypropylene composites prepared by injection moulding. Polymers for Advanced Technologies, 29(1), 433–441. (2018) IF = 2.137 https://doi.org/10.1002/pat.4132

S5 D. Vadas, Z. K. Nagy, I. Csontos, G. Marosi, K. Bocz: Effects of thermal annealing and solvent‑induced crystallization on the structure and properties of poly(lactic acid) microfibres produced by high‑speed electrospinning. Journal of Thermal Analysis and Calorimetry, 25. January (2020) IF = 2.471 https://doi.org/10.1007/s10973-019-09191-8

S6 K. Bocz, K. E. Decsov, A. Farkas, D. Vadas, T. Bárány, A. Wacha, A. Bóta, G. Marosi: Non-destructive characterisation of all-polypropylene composites using small angle X-ray scattering and polarized Raman spectroscopy. Composites: Part A: Applied Science and Manufacturing, 114, 250–257. (2018) IF = 4.514 https://doi.org/10.1016/j.compositesa.2018.08.020

S7 K. E. Decsov, K. Bocz, B. Szolnoki, S. Bourbigot, G. Fontaine, D. Vadas, G. Marosi: Development of Bioepoxy Resin Microencapsulated Ammonium-Polyphosphate for Flame Retardancy of Polylactic Acid. Molecules, 24(22), 4123. (2019) IF = 3.060 https://doi.org/10.3390/molecules24224123

S8 K. Bocz, B. Szolnoki, A. Farkas, E. Verret, D. Vadas, K. Decsov, G. Marosi: Optimal distribution of phosphorus compounds in multi-layered natural fabric reinforced biocomposites. Express Polymer Letters, 14(7), 606–618. (2020) IF = 3.083 https://doi.org/10.3144/expresspolymlett.2020.50

S9 K.Bocz, T. Igricz , Á. Kmetty, T. Tábi , B. Szabó, D. Vadas, L. Kiss, T. Vigh , G. Marosi: Funkcionalizált biopolimer habok fejlesztése szuperkritikus széndioxiddal segített extrúzióval. Polimerek, 2(2), 46–49. (2016)

S10 D. Vadas, K.Bocz, T. Igricz, T. Tábi, B. Szabó, G. Marosi: Égésgátolt politejsav habok előállítása szuperkritikus szén-dioxiddal segített extrúzióval. Polimerek, 3(5), 156–160. (2017)

S11 D. Vadas, D. Kmetykó, B. Szabó, G. Marosi, K.Bocz: Ömledékfúvással gyártott mikroszálak felhasználása önerősített politejsav kompozitok előállítására. Polimerek, 4(7-8), 245–250. (2018)

Table of links

Department of Organic Chemistry and Technology

Department of Polymer Engineering

https://www.plasticseurope.org/application/files/4315/1310/4805/plastic-the-fact-2016.pdf

https://assets.theoceancleanup.com/app/uploads/2019/05/TOC_map-gyres-02.jpg

https://ourworldindata.org/plastic-pollution

https://docs.european-bioplastics.org/publications/EUBP_Facts_and_figures.pdf

List of references

1 Á. Kmetty, T. Bárány, J. Karger-Kocsis: Self-reinforced polymeric materials: A review. Progress in Polymer Science, 35(10), 1288–1310. (2010) https://doi.org/10.1016/j.progpolymsci.2010.07.002

2 P.S. Liu, G.F. Chen: 8. Application of Polymer Foams. in: Porous Materials, Processing and Applications. Elsevier Science, Amsterdam, 383–408. (2014) Google Scholar

3 K. Marsh, B. Bugusu: Food Packaging—Roles, Materials, and Environmental Issues. Journal of Food Science, 72(3), 39–55 (2007) https://doi.org/10.1111/j.1750-3841.2007.00301.x

4 V. Bisinella, P. F. Albizzati, T. F. Astrup, A. Damgaard (Eds.): Life Cycle Assessment of grocery carrier bags. Danish Environmental Protection Agency. Miljoeprojekter, No. 1985 (2018) https://www2.mst.dk/Udgiv/publications/2018/02/978-87-93614-73-4.pdf

5 M. Pervaiz, S. Panthapulakkal, M. Sain, J. Tjong Emerging Trends in Automotive Lightweighting through Novel Composite Materials. Materials Sciences and Applications 7(1), 26–38.(2016) https://doi.org/10.4236/msa.2016.71004

6 J. R. Jambeck, R. Geyer, C. Wilcox, T. R. Siegler, M. Perryman, A. Andrady, R. Narayan, K. L. Law: Plastic waste inputs from land into the ocean. Science, 347(6223), 768–771.(2015) https://doi.org/10.1126/science.1260352