|

|

BMe Research Grant |

|

Pattantyús-Ábrahám Doctoral School of Mechanical Engineering

BME Faculty of Mechanical Engineering, Department of Energy Engineering

Supervisor: Dr. IMRE R. Attila

Constructing efficient and eco-friendly thermal power generation using the volumetric expander

Introducing the research area

Achieving sustainable development goals, energy policy, addressing climate change, and other international agreements all drive the need for reliable, eco-friendly, sustainable, and modern energy services, continuing to improve the efficiency of machines and devices used for energy conversion one of today's most important research topics [1,2]. Several large energy conversion systems across the world remain to be fueled by nuclear or fossil fuels. The thermodynamic efficiency of these conventional thermal energy conversion systems is, in many cases, still below 50% despite extensive efforts to improve the design and optimize the operating parameters [3]. To reduce energy losses in the energy conversion chain and improve the efficiency of power generation, several actions related to waste energy recovery and energy storage are being investigated. Along with these techniques, ongoing research focused on the creation of potential strategies to increase the thermodynamic efficiency of the power-generating cycles is very significant. One of the promising solutions is to advance the organic Rankine cycle (ORC) as power generation since it has the flexibility to adapt to different operating conditions and working fluids, easier integration of waste heat and cold energy, relatively low investment and maintenance cost, compact modular design, etc.

Brief introduction of the research place

The research takes place at the Department of Energy Engineering, BME, and the Department of Thermodynamics and Renewable Energy Sources, Wroclaw University of Science and Technology (WUST), Poland. Moreover, part of the research is carried out at the Centre for Energy Research, Hungary, and the Centre for Compressor Technology, City, University of London.

History and context of the research

Since the 2000s, research on the topic of ORC technology has been significantly increasing [4]. This technology is a typical Rankine cycle using organic working fluids instead of water as the medium inside the cycle. This ORC system is primarily installed in the mega-watts power range and very few plants exist in the kilo-watts power range [4] for some applications (e.g., waste heat recovery, cold energy utilization, geothermal heat, solar thermal, biomass, ocean thermal, etc.). When designing an eco-friendly power plant via ORC the biggest challenge is to meet some requirements such as higher efficiency, more eco-friendliness, greater safety, and more reasonable costs (investment, operational, and maintenance costs). Some complex designs are involved in designing ORC technology such as the selection of suitable working fluids, proper equipment, design, material, operation, maintenance, etc. Moreover, several turbines as primary expanders are used in the current ORC system making this technology relatively expensive and requiring high maintenance when installed for low-and medium-temperature ranges. For this reason, the research utilizing a volumetric expander as an alternative option for the prime mover of ORC (that is a built-in compact design with relatively more reasonable investment cost, low maintenance, etc.), can be promising for further application. To support the sustainable development objective and other international agreements in utilizing waste heat and renewable sources and mitigating the adverse environmental consequences, the next innovative generation of ORC technology is necessary.

The research goals, open questions

Although the first generation of ORC systems is already a mature technology for some applications, there is still a gap in knowledge and room for the development/advancement of this ORC technology. Therefore, the main aim of this research is to develop an efficient thermal power plant via ORC, considering suitable low-boiling working fluids and volumetric expansion machines (as an alternative option to turbines). Since some volumetric expanders can probably operate under wet conditions (two-phase), analyzing the performance of two-phase volumetric expanders is also one of the objectives of this research, which can improve the power cycle performance. To achieve the goal, some objectives are derived as follows: finding suitable organic working fluids (including some mixtures as a medium for the thermal power plant), designing thermodynamic power cycles, evaluating the performance of suitable volumetric expansion machines selected for ORC, comparing, and optimizing numerical modeling and experimental results, and describing the mathematical model and practical applications.

Methods

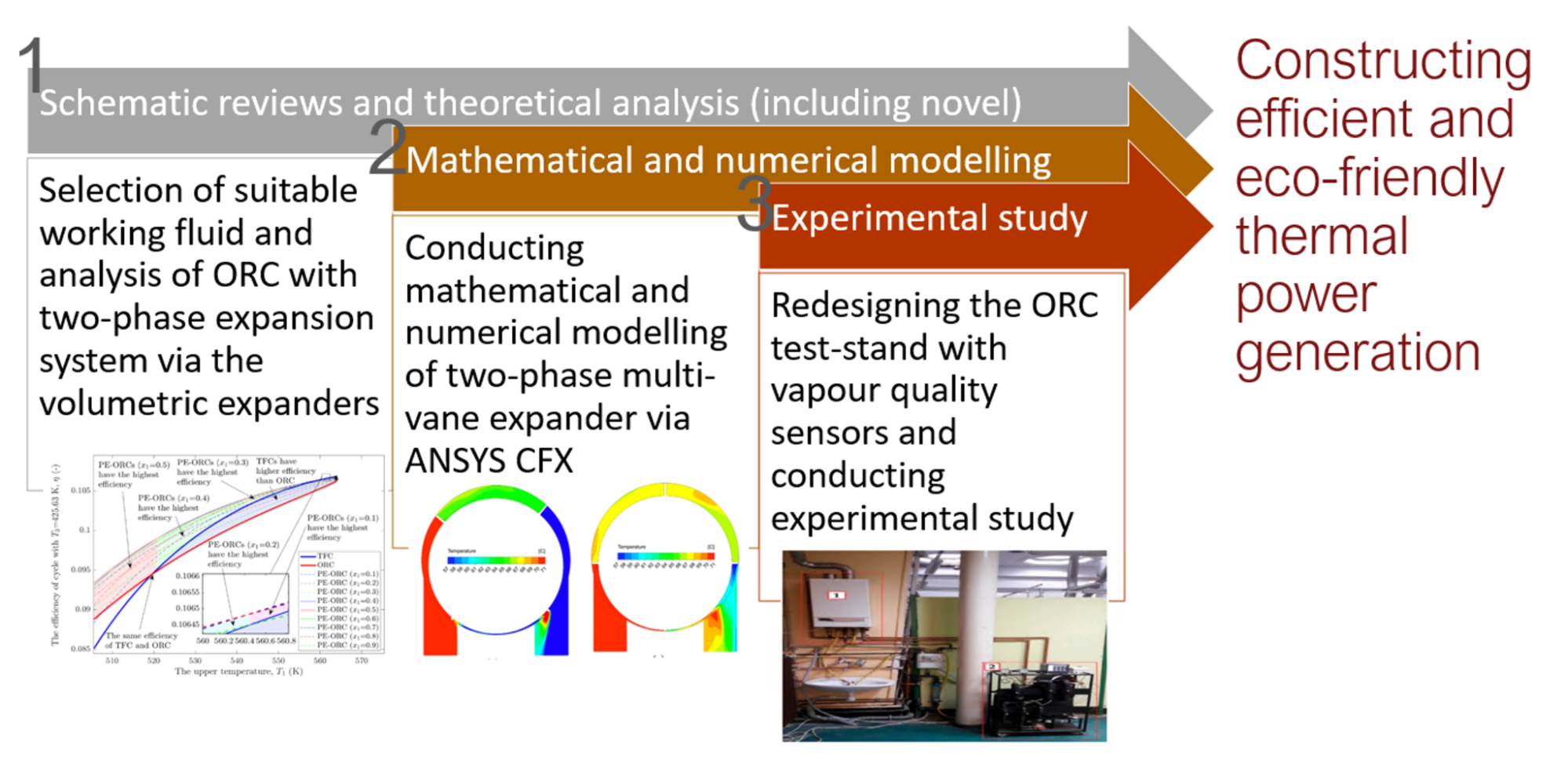

To accomplish the main goal and objective above mentioned, the research is divided into three parts illustrated in Fig. 1, as follows:

- The theoretical part,

This part entails the simulation modeling of thermodynamic power cycles in MATLAB configuration using existing thermal properties of low-boiling working fluids obtained from the National Institute of Standards and Technology (NIST), REFPROP, CoolProp, and other alternative sources. To comply with the worldwide agreement to minimize carbon emissions and other harmful environmental impacts, suitable working fluids as medium with zero ozone depletion potential, very low global warming potential, and safety considerations must be sought. This theoretical section focuses on using low-boiling, environmentally friendly working fluids, and innovative designs to increase the overall efficiency of thermodynamic power cycles. Part of the research is also being carried out in this phase in cooperation with the Centre for Energy Research in Budapest.

- The numerical part,

This part is the stage where the volumetric expander is numerically modeled and analyzed in the ANSYS CFX environment. In this initial study of the research, the multi-vane expander was selected. The numerical model of the two-phase condition will be also modeled for the two-phase volumetric expander in cooperation with the Centre for Compressor Technology at the City, University of London. This center has internationally leading research in the field of screw expanders and compressors (one of the volumetric expander types) which is in perfect harmony with research related to volumetric machines.

- The experimental part,

This part consists of experimental studies to validate the aforementioned model. Some of the multi-vane expanders used in this experiment were modified from the volumetric compressors on the market. The experimental test bench is currently being redesigned in order to achieve validated results, and two-phase measurement (vapor quality sensors) is also connected to the setup. This kind of research has not been conducted yet due to the previous limitations of the sensors. The expected results can therefore be state-of-the-art research that bridges the theoretical and practical aspects and can provide new data for the design of an efficient and more eco-friendly thermal power plant integrated with a two-phase expansion system.

Fig. 1. The methodology of the research, some pictures are taken from [S1, 5]

Results

ORC with a two-phase expansion system

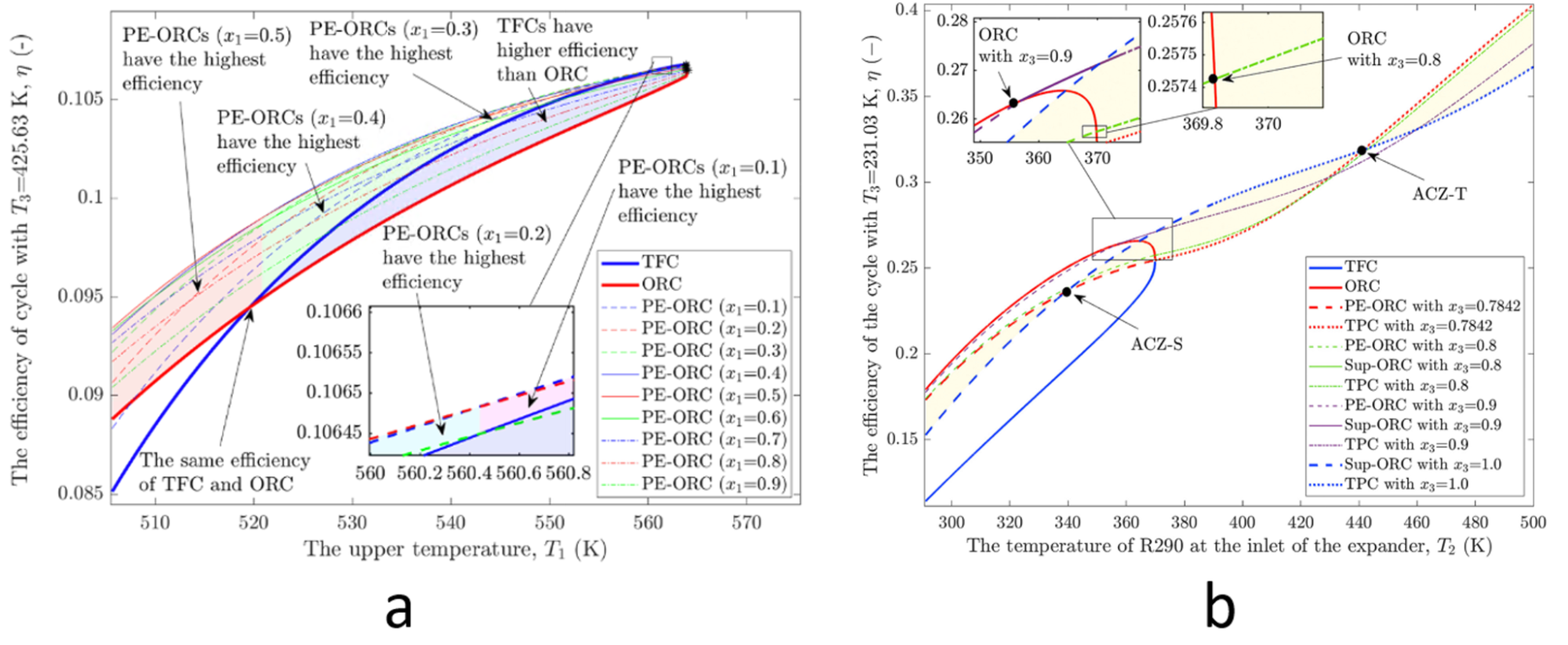

A preliminary study of two-phase expanders for ORC has been conducted; the obtained results show that typical rotary volumetric expanders can operate under two-phase (or wet conditions) conditions [S2]. The results of simulation modeling illustrated in Fig. 2a demonstrated that under certain conditions and using dry and isentropic working fluids, the overall cycle efficiency of the partially evaporated ORC (PE-ORC) using a two-phase expansion system can outperform the ORC and trilateral flash cycle (TFC) [S1]. Moreover, it also describes that typical maximal cycle efficiency is achieved near the critical point [S1, S3, S4]. New results have been obtained regarding the thermodynamic efficiency of subcritical and transcritical power cycles, namely that superheated ORC (Sup-ORC) efficiency with a two-phase expansion system can outperform maximal ORC efficiency and PE-ORC, as illustrated in Fig. 2b [S4].

Fig. 2. The obtained results of ORC with a two-phase expansion system in the efficiency-temperature diagram for (a) subcritical cycle and (b) subcritical and transcritical cycles [S1, S4]

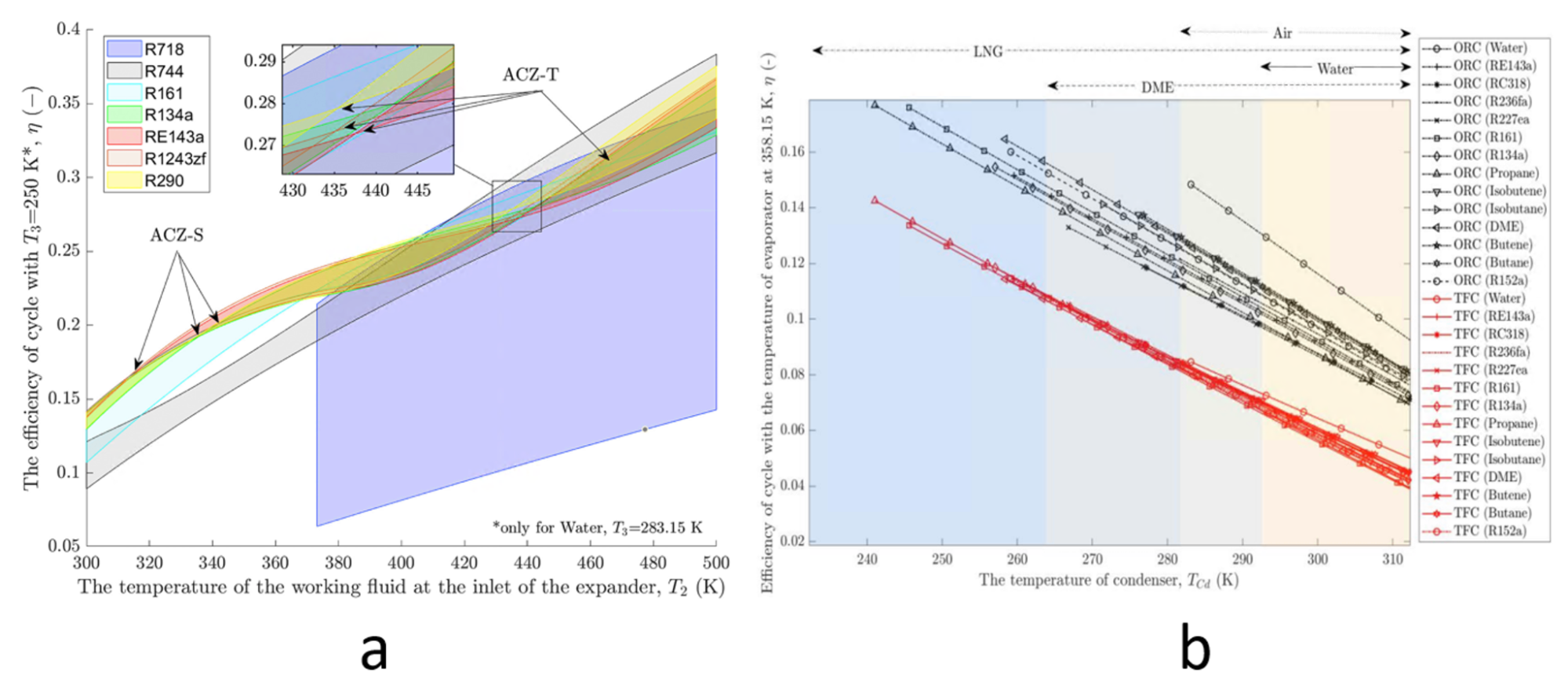

Working fluids and other integrated/combined system

In the current stage, the obtained results show the cycle performance using different working fluids and cooling sources, which is illustrated in Fig. 3 [S4, S5]. This shows that Propane (R290) can be a good candidate as a working fluid for ORC, as it has zero ODP and low GWP (but it is flammable) [S4, S5, 6]. Not only the two-phase expansion systems integrated with ORC but also the thermal energy storage (TES) system showed good performance in handling intermittent and fluctuating heat sources (waste heat and renewable) [S6, S7, S8]. Moreover, the heat transfer analysis of a multi-vane expander has been studied [S9] and deeper investigation is needed to understand and control the performance. The Carnot battery technology can be the next generation of ORC as it can be integrated with a heat pump and TES. A preliminary study of two-phase expansion in Carnot battery via the reversible Rankine-based thermodynamic cycle (RRTC) has been reported [S10].

Fig. 3. The obtained results of simulation modeling for (a) different working fluids for subcritical and transcritical cycles and (b) different working fluids and different cooling sources for ORC and TFC [S4, S5]

Applications

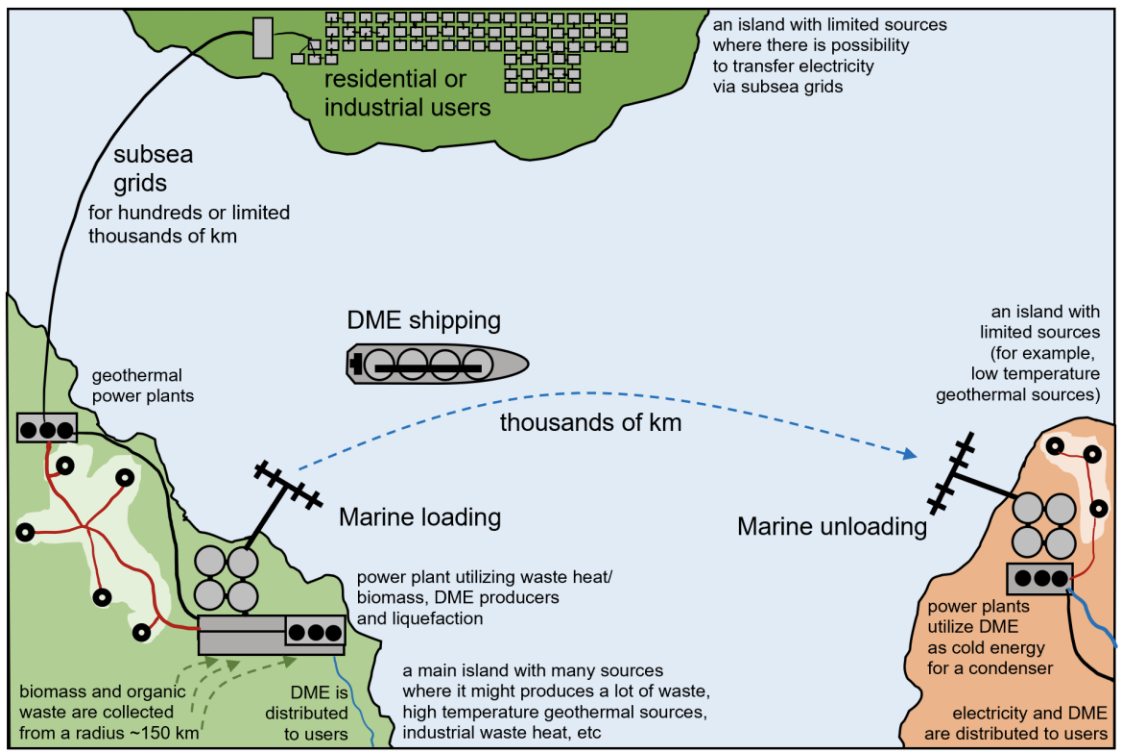

A circular economy approach is now a good waste-to-energy strategy that might help reduce residual waste in the existing process [S11]. For instance, heat from abandoned oil and gas wells and waste heat from various industrial operations can also be used to generate power [S12]. Based on the current results, ORC can be used in several industries to improve the efficiency of the current system, such as the waste heat utilization in paint shops of automotive manufacturers [S13]. Furthermore, ORC can help improve the value chain of the geothermal energy system by integrating with cold energy utilization from the dimethyl ether (DME) regasification system, as illustrated in Fig. 4 [S14].

Fig. 4. The schematic novel of an integrated system: geothermal-waste-cold energy [S8]

Expected impact and further research

The results of the research have a significant impact on the redesign and construction of thermal power plants in order to boost clean, efficient, and modern energy conversion systems that utilize eco-friendly organic working fluids in the future. The following research focuses on the numerical modeling and experimental study of ORC with a two-phase expansion system and publishes some results in high-impact journals. Moreover, the author intends to conduct research in mixtures and integrated ORC systems (including Carnot battery technology) to utilize cold energy from hydrogen, nitrogen, liquefied natural gas, and others (which may be the future energy sources) as power generation.

Publications, references, links

List of corresponding own publications with the sum of impact factors=25.543.

[S1] Daniarta, S., Kolasiński, P., Imre, A. R. 2021. Thermodynamic efficiency of trilateral flash cycle, organic Rankine cycle and partially evaporated organic Rankine cycle. Energy Conversion and Management, 249, 114731. IF=9.709.

DOI: https://doi.org/10.1016/j.enconman.2021.114731

[S2] Daniarta, S., Kolasiński, P. 2021. A preliminary study of two-phase volumetric expanders and their application in ORC systems. In Proceedings of the 6th International Seminar on ORC Power Systems, Munich, Germany.

DOI: https://doi.org/10.14459/2021mp1633105

[S3] Daniarta, S., Imre, A. R., & Kolasiński, P. 2021. The efficiency of transcritical CO 2 cycle near the critical point and with high temperature. In MATEC Web of Conferences (Vol. 345). EDP Sciences.

DOI: https://doi.org/10.1051/matecconf/202134500005

[S4] Daniarta, S., Imre, A. R., Kolasiński, P. 2022. Thermodynamic efficiency of subcritical and transcritical power cycles utilizing selected ACZ working fluids. Energy, 124432. IF=7.147.

DOI: https://doi.org/10.1016/j.energy.2022.124432

[S5] Daniarta, S., Kolasiński, P. 2022. A Comparative Study of Cooling Sources in Organic Rankine Cycle for Low-Temperature Geothermal Heat Sources. In IOP Conference Series: Earth and Environmental Science (Vol. 1014, No. 1, p. 012008). IOP Publishing.

DOI: https://doi.org/10.1088/1755-1315/1014/1/012008

[S6] Daniarta, S., Nemś, M., Kolasiński, P., Pomorski, M. 2022. Sizing the Thermal Energy Storage Device Utilizing Phase Change Material (PCM) for Low-Temperature Organic Rankine Cycle Systems Employing Selected Hydrocarbons. Energies, 15(3), 956. IF=3.004.

DOI: https://doi.org/10.3390/en15030956

[S7] Kolasiński, P., Daniarta, S. 2021. Sizing the thermal energy storage (TES) device for organic Rankine cycle (ORC) power systems. In MATEC Web of Conferences (Vol. 345). EDP Sciences.

DOI: https://doi.org/10.1051/matecconf/202134500018

[S8] Daniarta, S., Kolasiński, P. 2021. Features and Characteristics of Low-Grade Heat Storage for Organic Rankine Cycle. In Proceedings of the 6th International Seminar on ORC Power Systems, Munich, Germany.

DOI: https://doi.org/10.14459/2021mp1633107

[S9] Błasiak, P., Kolasiński, P., Daniarta, S. 2021. Analysis of heat transfer within rotary vane expander. In Proceedings of the 6th International Seminar on ORC Power Systems, Munich, Germany.

DOI: https://doi.org/10.14459/2021mp1633106

[S10] Daniarta, S., Kolasiński, P., Imre, A. R. 2022. A Preliminary Design and Modeling Analysis of Two-Phase Volumetric Expanders for a Novel Reversible Organic Rankine-Based Cycle for Carnot Battery Technology. Applied Sciences, 12(7), 3557. IF=2.679.

DOI: https://doi.org/10.3390/app12073557

[S11] Daniarta, S., 2021. Waste-to-Energy Solusi Peningkatan Efisiensi Energi. in Indonesia Emas Berkelanjutan 2045: Kumpulan Pemikiran Pelajar Indonesia Sedunia Seri 8 Energi.

DOI: https://doi.org/10.14203/press.360

[S12] Daniarta, S., Putranto, R P., Putra, N O. 2021. Dinamika Migas dan Panas Bumi di Indonesia. in Indonesia Emas Berkelanjutan 2045: Kumpulan Pemikiran Pelajar Indonesia Sedunia Seri 8 Energi.

DOI: https://doi.org/10.14203/press.360

[S13] Daniarta, S., Kolasiński, P., Rogosz, B. 2022. Waste Heat Recovery in Automotive Paint Shop via Organic Rankine Cycle and Thermal Energy Storage System—Selected Thermodynamic Issues. Energies, 15(6), 2239. IF=3.004.

DOI: https://doi.org/10.3390/en15062239

[S14] Daniarta, S., Kolasiński, P. 2021. An integration of geothermal energy, waste, and cold energy system employing the technology of organic Rankine cycle. In Proceedings of the 6th International Seminar on ORC Power Systems.

DOI: https://doi.org/10.14459/2021mp1633104

Table of links.

Department of Energy Engineering, BME

Centre for Compressor Technology, City, University of London

selection of suitable working fluids

List of references.

[1] Elavarasan, R. M., Pugazhendhi, R., Jamal, T., Dyduch, J., Arif, M. T., Kumar, N. M., ... Nadarajah, M. 2021. Envisioning the UN Sustainable Development Goals (SDGs) through the lens of energy sustainability (SDG 7) in the post-COVID-19 world. Applied Energy, 292, 116665.

DOI: https://doi.org/10.1016/j.apenergy.2021.116665

[2] McCauley, D., Ramasar, V., Heffron, R. J., Sovacool, B. K., Mebratu, D., & Mundaca, L. 2019. Energy justice in the transition to low carbon energy systems: Exploring key themes in interdisciplinary research. Applied Energy, 233, 916–921.

DOI: https://doi.org/10.1016/j.apenergy.2018.10.005

[3] Suppes, G. J., & Storvick, T. S. 2007. Production of electricity. Sustainable nuclear power, 185–200.

[4] Quoilin, S., Van Den Broek, M., Declaye, S., Dewallef, P., & Lemort, V. 2013. Techno-economic survey of Organic Rankine Cycle (ORC) systems. Renewable and sustainable energy reviews, 22, 168–186.

DOI: https://doi.org/10.1016/j.rser.2013.01.028

[5] Kolasiński, P., Błasiak, P., & Rak, J. 2016. Experimental and numerical analyses on the rotary vane expander operating conditions in a micro-organic Rankine cycle system. Energies, 9(8), 606.

DOI: https://doi.org/10.3390/en9080606

[6] Daniarta, S., & Imre, A. R. 2020. Cold energy utilization in LNG regasification system using organic Rankine cycle and trilateral flash cycle. Periodica Polytechnica Mechanical Engineering, 64(4), 342–349.

DOI: https://doi.org/10.3311/PPme.16668