|

|

BMe Research Grant |

|

Géza Pattantyús-Ábrahám Doctoral School of Mechanical Engineering

BME Faculty of Mechanical Engineering, Department of Energy Engineering

Supervisor: Dr. Józsa Viktor

Utilization of renewable fuel in a novel, ultra-low emission burner

Introducing the research area

For reaching sustainability, our energy-consuming habits must be considerably transformed. However, several thermal processes are economically unfeasible without combustion. The good news is that with alternative fuels, we can do a lot in favor of our environment because, over 1000 K reaction temperature, the origin of the fuels is of secondary importance. A few decades ago, gas turbines and boilers with convective heat exchangers operated exclusively with non-premixed flames. Although such an operation is simple, advancement was necessary due to the pollutant emission regulations. It is important to notice here that the combustion of hydrocarbons inevitably produces carbon dioxide and water vapor; however, carbon monoxide, CO, and nitrogen oxide, NOX are pollutants, and their concentration can be reduced with careful design. Therefore, during my research, I focused primarily on these two pollutants. Compared to the initial designs, today’s combustion systems feature one magnitude lower pollutant emission with premixed, V-shaped flames. However, to reduce environmental pollution and comply with stricter regulations, further developments are needed to keep these pollutants at a few ppm instead of the current 100 ppm. Distributed combustion, however, requires a larger combustion chamber, providing halved NOX emission than V-shaped flames. Furthermore, the combustion noise, mechanical load, and hence physiological load of the operators are all reduced. Would distributed combustion be the future? Figure 1 presents the mentioned three flame types.

![]()

Figure 1. Flame shapes. From left to right: non-premixed straight [1], premixed V-shaped, and distributed flames [S1].

Brief introduction of the research place

The infrastructure for the research is provided in the György Jendrassik Laboratory of the Department of Energy Engineering. Combustion tests are accomplished in a semi-industrial environment with borrowed advanced optical instruments on a test rig designed and installed by the members of the Combustion Research Group, led by Dr. Viktor Józsa. Domestic and international researchers are continuously participating in the research.

History and context of the research

Nowadays, MILD (Moderate or Intense, Low-oxygen Dilution), also known as distributed or flameless combustion, is a hot research topic. The latter name indicates that the flame is invisible to the human eye or is barely visible. The theory of this combustion concept is more than a half-century old; however, it is rarely employed in practice. Distributed combustion is characterized by low combustion temperature and pollutant emission. The reactants have to be preheated above their autoignition temperature for this combustion mode, and the oxidizer must be diluted by inert gas or flue gas [2]. The dilution of the oxidizer (typically air) is easy to realize in a laboratory test rig by, e.g., N2 or CO2, but in industry or transport, these solutions are unfeasible [3,4]. Flue gas recirculation is performed by an auxiliary system, which requires the upgrade of the entire combustion system in practice [5]. A more favorable method is internal recirculation.

Recently, our research group has designed and installed a combustion concept called MTC (Mixture Temperature-Controlled), which can operate with distributed combustion, similar to MILD combustion. This combustion mode results in more homogeneous mixture formation and heat release than V-shaped flames. Therefore, its CO and NOX emission is marginal. Compared to MILD combustion, the novelty of the MTC concept is that there is no need for flue gas recirculation, which is a significant advantage in, e.g., aero engines.

The research goals, open questions

Of the alternative liquid fuels, those based on fatty acids are the most problematic to combust. It is easy to convert these into biodiesels, which are well-known and compatible with our current engines, unlike hydrogen. The following examples should be understood as model fuels, which represent the combustion of similar fuels, meaning that, for example, the results are valid for biodiesels made from algae. Distributed combustion was previously achieved by using coconut methyl ester (CME) [S2]. The current research investigates the combustion of less volatile biodiesels, ones derived from waste cooking oil (WCO), and palm methyl ester (PME). The study aims to clarify the boundaries of distributed combustion, including the physical-chemical properties of the fuels and the operating parameters.

Methods

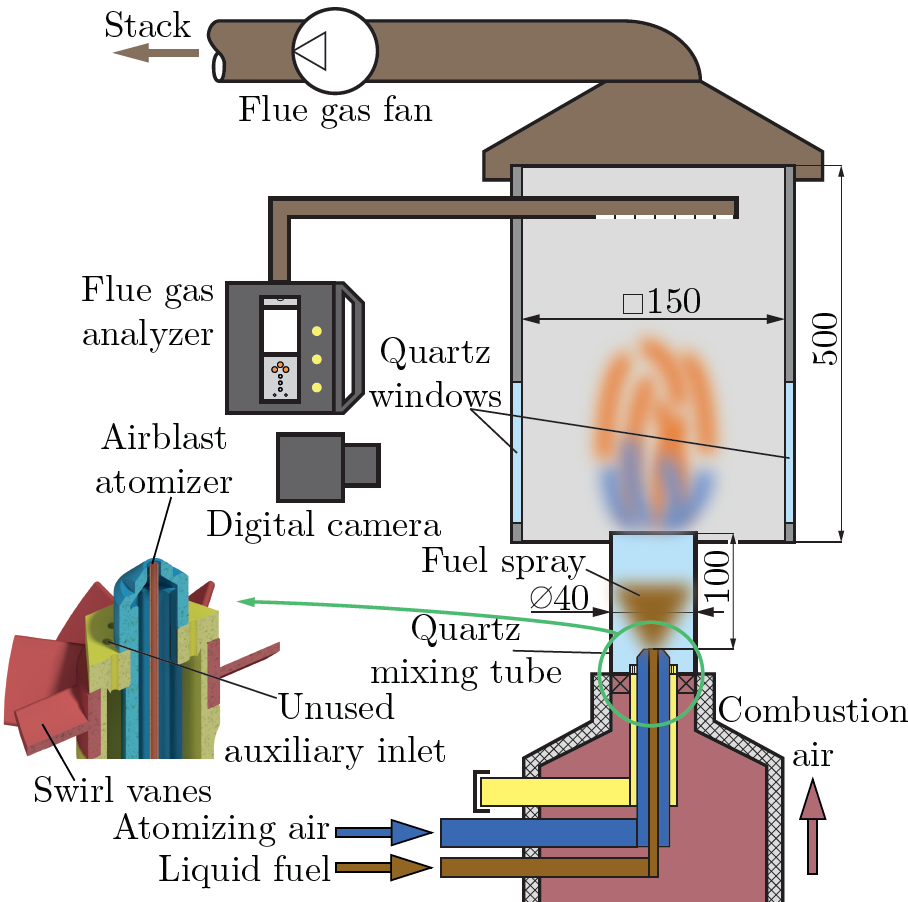

The schematic setup of the test rig is shown in Fig. 2. From the air blast atomizer, fuel droplets discharge into a mixing tube and form a homogenous mixture with the preheated, swirling combustion air if the mixture temperature is lower than the ignition temperature at the mixing tube outlet. In that case, combustion occurs downstream in the combustion chamber with a distributed flame.

Figure 2. Section of the test rig.

During the combustion tests, the effect of air-to-fuel equivalence ratio, combustion air temperature, and atomizing air pressure was investigated. All biodiesel was combusted as neat (B100) and a mixture with diesel fuel (D) in 25, 50, and 75 V/V% biodiesel shares (B25, B50, B75).

A spectrometer, a photomultiplier tube, and a digital camera were installed to record the chemiluminescent intensity and flame images optically. A microphone was installed in the lower third of the combustion chamber for acoustic evaluation. During the tests, the physical properties of flow rates were recorded together with emission data.

Three distinct flame shapes were observed during the combustion tests of CME, PME, and WCO: straight, V-shaped, and distributed flames. However, stable combustion lasting for at least a few minutes occurred only in the case of straight and distributed flames. In the measurement setups, where the flame shape was altering, the transition frequency was 1 Hz between two flame shapes, which is better to avoid in the industry. Therefore, it is critical to know these states well. Figure 3 presents selected flame images recorded during the tests. In the first image from the left, a luminous, yellow, straight flame can be seen. At low atomizing pressure, larger fuel droplets are produced. Their residence time in the mixing tube is insufficient for complete evaporation; therefore, the liquid fuel droplets burn in the combustion chamber, which leads to soot formation. Later, this soot completely burns out; it cannot be found on the walls of the combustion chamber or in the flue gas. However, the local high-temperature zones lead to high NOX formation.

The second image shows a smaller, more compact, purple-blueish flame. At higher atomizing pressure, smaller droplets are formed, which can completely evaporate in the mixing tube, and a more homogenous fuel-air mixture enters the combustion chamber. When the third image was recorded, V-shaped and straight flames alternated. The blue cone of the V-shaped flame can be seen, as well as the yellow flares of a straight flame.

The last two images show distributed combustion, mostly low luminosity, and in blue color. These images are relatively luminous. The purplish color of CME flame is due to the different reaction pathways of burning an oxygenated fuel, which was also studied by Chong et al. [6] in the case of sunflower biodiesel combustion.

Figure 3. Selected flame images. From left to right: CME B25 0.3 bar 250°C, PME B50 0.9 bar 200°C, WCO B100 0.3 bar 250°C, CME B50 0.3 bar 250°C, WCO B75 0.9 bar 200°C.

Results

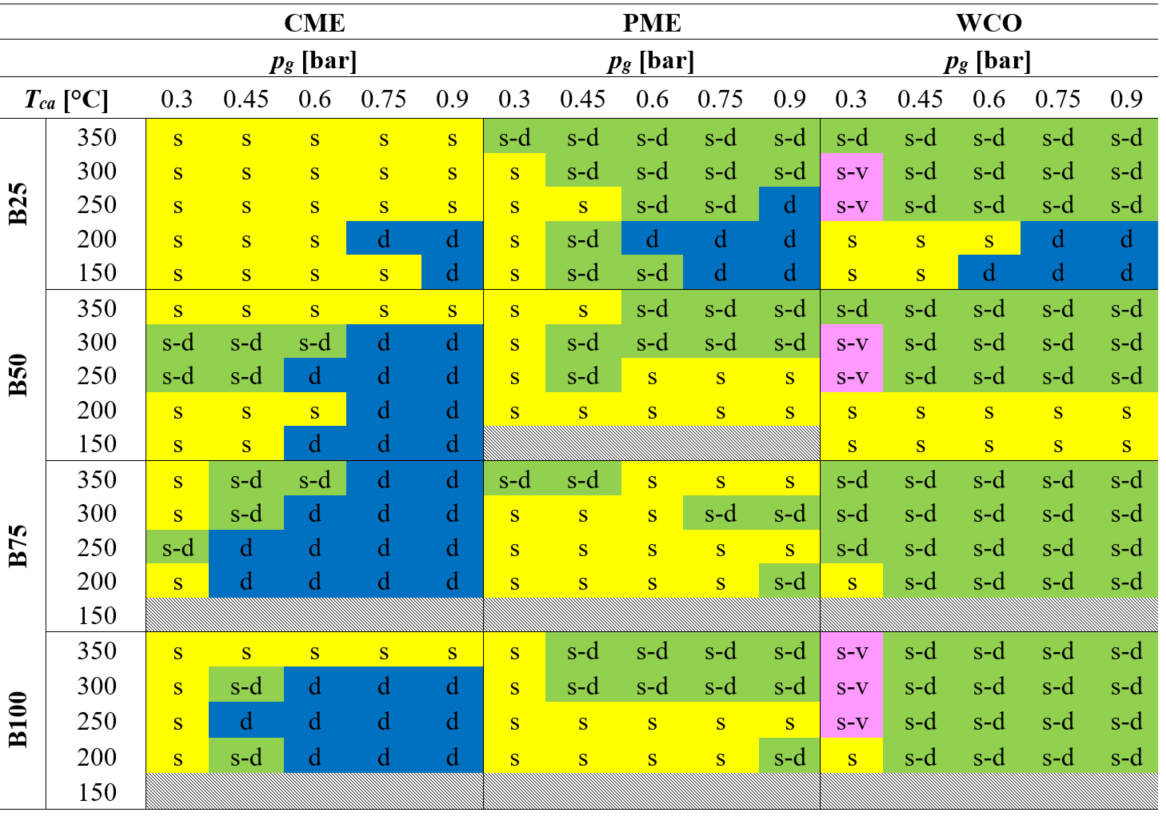

From our results so far, the characteristics of distributed combustion and the accompanying low CO and NOX emission are presented at a constant air-to-fuel equivalence ratio, corresponding to 4.2% dry flue gas oxygen concentration. In Fig. 4, the flame shapes are presented for all measurement conditions. At high biodiesel content, 150°C combustion air preheating temperature was not sufficient for the evaporation of the droplets; therefore, unstable combustion could be observed here. CME contains shorter chain fatty acids than PME and WCO; therefore, its viscosity and volatility are lower, enabling stable distributed combustion in a wider parameter range. The 25 V/V% blends of all three biodiesel showed distributed combustion in the same parameter range at higher atomizing pressure and lower combustion and preheating temperature.

Figure 5 presents the measured NOX emission converted to 15% flue gas oxygen content to ease comparison with the regulations of new gas turbine power installations. The 2015/2193 EU directive allows 75 mg/Nm3 NOX emission for new equipment. In all measurement setups, the NOX emission is below this limit, even the yellow luminous flames at low atomizing pressure and high combustion air temperature. For the industry, a significant result is a ratio in the NOX emission reduction between the different flame shapes. Comparing Fig. 4 and 5, operating conditions can be identified according to the flame shapes. NOX emissions are known to drop as temperature drops. It can be noticed that by reaching stable distributed combustion, the NOX emission drops drastically. By maintaining distributed combustion, the NOX emission can be kept below 20 mg/Nm3, which is expected to meet the requirements of upcoming regulations. For all fuels and measurement setups, the CO emission was below the measurement threshold, which indicates the complete combustion of the fuel.

Figure 4. Flame shapes in all measurement setups. Straight (s, yellow) and distributed (d, blue) flames, and flames alternating between straight and V-shaped (s-v, pink) and between straight and distributed (s-d, green). At the hatched setups, no continuous combustion was achieved.

Figure 5. NOX emission converted to 15% flue gas oxygen content.

Expected impact and further research

According to our combustion tests, liquid fuels with low volatility can be combusted with low pollutant emission, which is achieved through distributed combustion. In all measurement setups, NOX emission was below 20 mg/Nm3, far below the 75 mg/Nm3 limit defined in the 2015/2193 EU directive for new gas turbine power installations. The CO emission of the combustion was minimal, a few mg/Nm3, which practically means the complete combustion of the fuel. The industrial applicability of the combustion concept was demonstrated.

The aim of further research is the optical evaluation of the flame using bandpass filters and laser-based particle image velocimetry (PIV) measurements. These tests facilitate our understanding of distributed combustion and its implementation in industrial applications.

Publications, references, links

List of corresponding own publications (cumulative IF: 36.26):

[S8] Hidegh Gy., Józsa V.: Folyadéktüzelés károsanyag és kemilumineszcens emissziójának elemzése változó porlasztónyomás és levegő-előmelegítés mellett. Budapest, 29 November, 2019. 5. MÉB Égéstudományi Konferencia, CD publication, Ed: Magyar Égéstudományi Bizottság (2020)

Proceedings of the 9th European Combustion Meeting, Paper: Paper_S2_AIII_68 , 5 p. (2019)

Proceedings of the First International Conference on Smart Energy Carriers, Paper: PVI-2 (2019)

Table of links:

List of references:

[2] Cavaliere A, De Joannon M. Mild combustion. Prog Energy Combust Sci 2004;30:329–66.