|

|

BMe Research Grant |

|

Doctoral School of Informatics

Department of Automation and Applied Informatics

Supervisor: Dr. CSORBA Kristóf

Developing In-Line Processes for viscosity measurement in pharmaceutical manufacturing

Introducing the research area

The pharmaceutical industry is under constant pressure to bring safe and effective drugs to market more efficiently. This is mainly due to the increasing demand for new treatments, growing competition, and regulatory constraints imposed by entities such as the U.S. Food and Drug Administration (FDA) and other regulatory bodies. The viscosity of a liquid is the property that measures the liquid internal resistance to flow or shear. This fundamental characteristic parameter is essential for quality control not only in the pharmaceutical industry but also in various industrial areas such as food, chemical, and energy-related sectors. The application of machine learning techniques in the area of viscosity measurement could lead to significant improvements in the pharmaceutical industry. Our research findings indicate that integrating machine learning algorithms with appropriate data to develop in-line processes for viscosity measurement holds significant potential and value.

Brief introduction of the research place

The research is carried out in BME PharmTech Lab, in partnership with the Faculty of Chemistry, with the purpose of supporting pharmaceutical manufacturing research and development processes with information technology solutions.

History and context of the research

Viscosity, a fundamental property of liquids, measures their internal resistance to flow. Capillary viscometers are commonly used for viscosity measurement, but their high cost and complexity present challenges when real-time and accurate viscosity information is required. Recent research studies have explored the correlation between liquid droplets and viscosity, revealing that droplet characteristics can offer valuable insights into viscosity. Leveraging the capabilities of convolutional neural networks, which autonomously learn and extract relevant features from images, along with the rich information conveyed by liquid droplet images, emerges as a promising non-invasive and continuous approach to estimating viscosity values for liquids in the pharmaceutical industry.

The research goals, open questions

This research aims to develop a non-invasive and continuous method using liquid droplet images for estimating viscosity values. By leveraging convolutional neural networks, the goal is to autonomously extract relevant features from the droplet images and establish a cost-effective alternative to traditional viscometers. The research also tries to explore the correlation between droplet characteristics and viscosity, enabling more accurate and real-time viscosity measurements. Open questions to address include identifying the most significant droplet characteristics that correlate with viscosity and developing effective methods for feature extraction from the droplet images. Also, optimizing and training convolutional neural networks for accurate viscosity estimation. Additionally, the research investigates the accuracy, reliability, and integration potential of the non-invasive viscosity estimation method into existing quality control processes. The limitations, sources of error, and environmental factors affecting the proposed method will be assessed, along with its real-time monitoring capabilities and comparisons to other non-invasive viscosity measurement techniques in terms of accuracy, cost-effectiveness, and implementation feasibility.

Methods

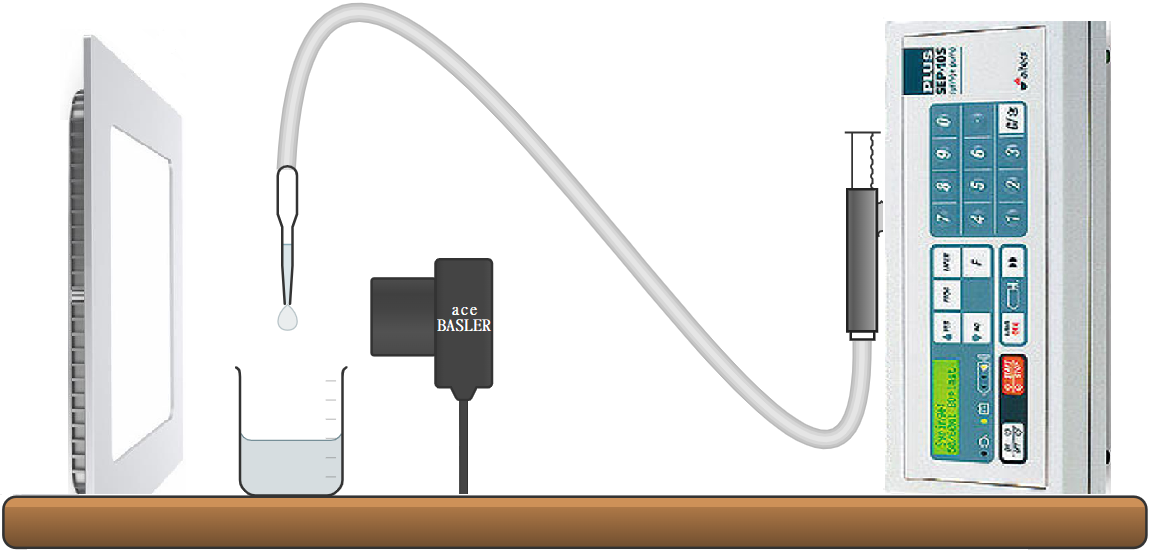

A total of fourteen solution samples were created by combining PVP (Polyvinylpyrrolidone) solution and distilled water in various ratios, resulting in solutions with a range of viscosity values. The viscosity values of the samples were quantified using the DMA 4500 M viscometer. The objective was to capture the formation process of droplets from each of these solutions via video recording. The liquid sample was dispensed from an automatic syringe pump through a transparent rubber tube to a pipette dropper at a controlled rate. A high-quality monochrome camera was positioned behind the dropper to capture videos of the droplet formation process as illustrated in Figure 1.

Figure 1. Experimental Setup/ Experimental Setup in test.

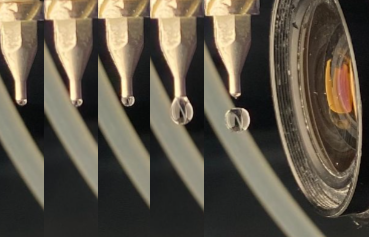

The experiment yielded a collection of fourteen videos that offer valuable insights into the formation stages of droplets, providing informative data on their characteristics as shown in Figure 2. We extracted 6074 images of droplets in the “before-detachment” state. We carefully examined each image and made adjustments when necessary, so that any differences between the images only reflected changes in the droplet characteristics.

Figure 2. Video of Droplet of Water-PVP solution.

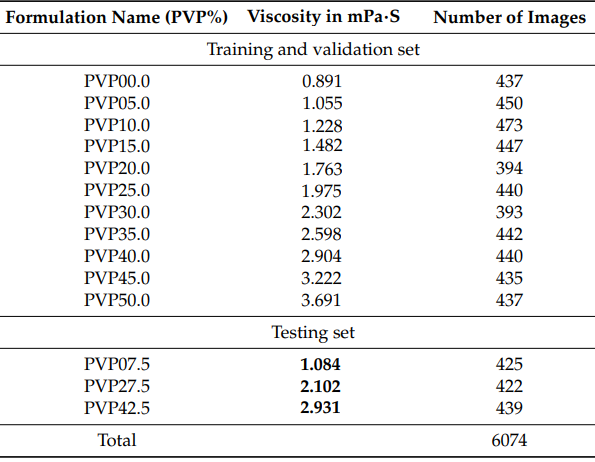

Convolutional neural network (CNN) models were created using ReLU activation function, Adam optimizer, and the mean squared error (MSE) for the loss function. The dataset is presented in Figure 3. The samples chosen for validation were selected uniformly from the training data. For testing, we used data from three distinct chemical formulations (PVP07.5, PVP27.5, and PVP42.5) that were not included in the training or validation data of the models.

Figure 3. Dataset used for CNN training and testing along with the different formulation names and their viscosities.

Results

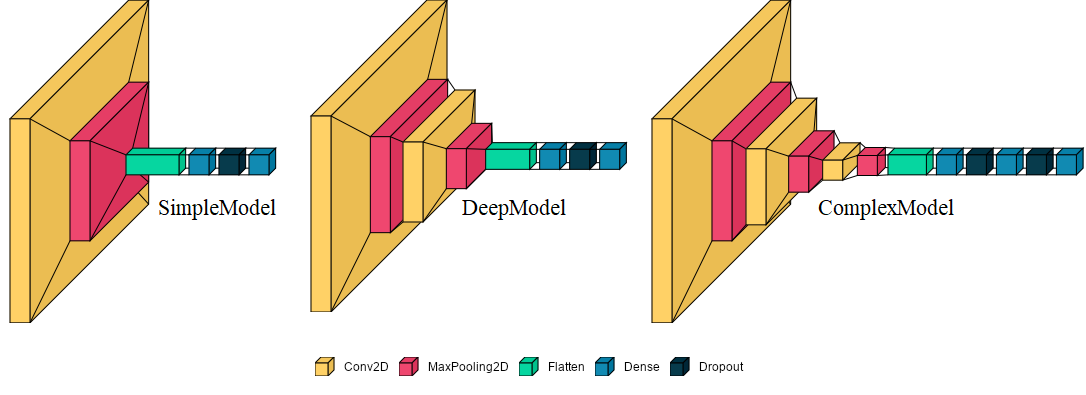

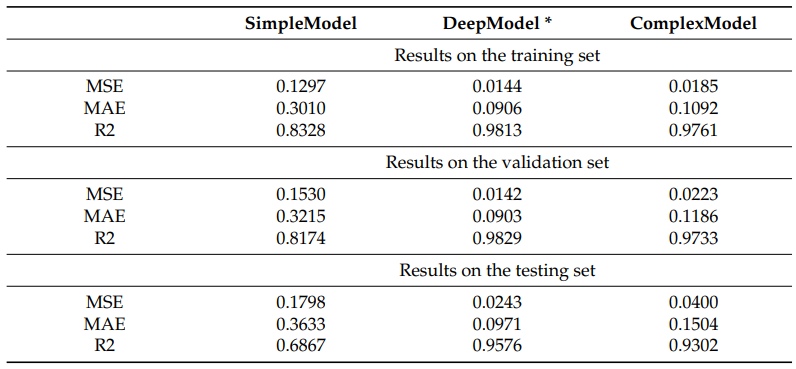

Multiple CNN models were created, each with a different architecture that determines how it processes the input images and makes predictions as shown in Figure 4, and their results are presented in Figure 5.

Figure 4. CNN models architectures

Figure 5. Results of the different models on the training, validation, and testing sets. The best-performing model is marked with*.

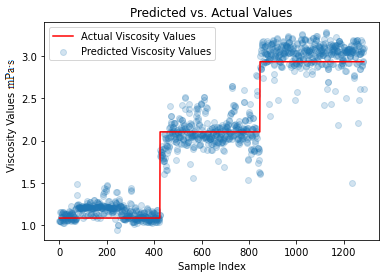

The DeepModel architecture was found to be the most effective for this task, suggesting that for a similar task, a moderate level of complexity is optimal for capturing the relevant features in the images The results indicate that the model is both robust and capable of generalization, as it was able to accurately estimate the viscosity values of new, unseen images that were not used during training. Most importantly, the model was able to predict the viscosity of the testing set images of water–PVP formulations that it had not been previously exposed to or trained on. The viscosity values predicted by the DeepModel on the testing set are presented in Figure 6.

Figure 6. Predicted vs. actual viscosity values of DeepModel on testing set.

The results suggest that the model is not only able to learn from the training data but can also capture the underlying patterns in the samples that can generalize well to new, similar chemical formulations. Our findings suggest that CNNs offer an advantage in that they can learn and identify patterns in a dataset without prior knowledge of the underlying physical laws governing the behavior of liquids. Specifically, our DeepModel trained on water and PVP solutions can accurately predict the viscosity of liquids of the same composition. This method has potential applications in scenarios where real-time monitoring of liquid viscosity is required. It can serve as a cost-effective alternative for certain use cases. Additionally, the calibration process is simple and can be completed in a matter of hours with only a few solutions required.

Expected impact and further research

The proposed non-invasive viscosity estimation method using liquid droplet images and convolutional neural networks holds significant promise for the pharmaceutical industry and other sectors. It offers a cost-effective and continuous approach to viscosity measurement, enhancing quality control processes. The findings suggest that the DeepModel architecture exhibits robustness and generalizability, accurately predicting viscosity values for unseen images of water-pvp formulations. The potential impact includes real-time viscosity monitoring, cost savings, and simplified calibration processes. Future research could focus on refining the model's performance, exploring applications in different liquid systems, and investigating the integration of the method into industrial manufacturing processes for enhanced process control and optimization.

Publications, references, links

List of corresponding own publications(cumulative IF: 6.70):

[1] Mrad MA, Csorba K, Galata DL, Nagy ZK, Charaf H. Droplet-Based Estimation of Viscosity of Water–PVP Solutions Using Convolutional Neural Networks. Processes. 2023; 11(7):1917. https://doi.org/10.3390/pr11071917

[2] Mrad MA, Csorba K, Galata DL, Nagy ZK. Classification of Droplets of Water-PVP Solutions with Different Viscosity Values Using Artificial Neural Networks. Processes. 2022; 10(9):1780. https://doi.org/10.3390/pr10091780

[3] Mrad, M. A., Csorba, K., Galata, D. L., Nagy, Z. K., Nagy, B., & Charaf, H (2023, June). Viscosity Estimation of Water-PVP Solutions from Droplets using Artificial Neural Networks and Image Processing. In: International Conference on Artificial Intelligence and Soft Computing. Cham: Springer International Publishing.

[4] Mrad MA, Csorba K, Galata DL, Nagy ZK. Droplet-Based Prediction of Viscosity of Water-PVP Solutions Using Convolutional Neural Networks. In: Proceedings of the Automation and Applied Computer Science Workshop 2023.

Table of links: