BMe Research Grant

|

BMe Research Grant |

|

Dental implantation is currently the most commonly used and physiologically the most favourable procedure for tooth replacement in dental surgery. Dental implants are artificial tooth root replacements. They are implanted in the jaw bones during small surgical operations to hold the prosthesis and to fasten it to the bone. Implants can have either advantageous or destructive effect on the surrounding bone, depending on several physiological, material and mechanical factors. In the light of this, implants transferring occlusal forces to bone within physiologic limits and having a geometry capable of enhancing bone formation should be applied. To this, stress and strain distributions around different types of dental implants need to be assessed. Being a destructive test, the straightforward procedure of direct mechanical testing has limitations. Therefore, this method is not applicable in humans and its usability is restricted in animal tests. The most general method for estimating the biomechanical behaviour of the bone is finite element analysis (FEA).

Dental implants

The Department of Structural Mechanics is a department –

in the Faculty of Civil Engineering of the BUTE – with outstanding research

activity. Besides our principal interest, the basic research in mechanics, the

researchers of the Department are also involved in several civil engineering

topics as well as in the science of biomechanics.

A basic role of our department is tuition – basic mechanics for civil engineers – comes with great

responsibility.

Great efforts have been made to decrease peak

stresses and to obtain more even stress distribution in the bone around implants

by choosing more favourable thread formation, increasing the length or the

diameter of the implant or controlling the method of load transfer from the

prosthetic component. In the aspect of oral implantation in the upper- and

lower-jawbones (maxilla and mandible) the finite element models published so far

consider the trabecular bone substance as a continuum. The macroscopic geometry of the implant has been modelled in FEA under the assumptions that the materials are homogeneous and linear with elastic material behaviour. At the

bone-implant interface most finite element models assume optimal

osseointegration, meaning that cortical and trabecular bone are perfectly bonded

to the implant.

The microstructural conformation of

the trabecular bone influences the overall mechanical properties of the bone

tissue. Several microstructural models have been developed for simulating the

mechanical behaviour of different types of bones in the human skeleton. In the

majority of cases, the models are from the vertebral or the femoral bone

substance and not from the mandible or maxilla and include no implants in or

cortical layer around the examined trabecular bone. In most studies models are

generated directly from computer reconstructions of the bone – mostly obtained

by means of micro-computed tomography images (3D high resolution images) – and

mechanical tests are simulated to determine mechanical properties of the bone

specimen.

Within the framework of my PhD study I deal with the finite element modelling of the bone surrounding dental implants in special consideration of the microstructure of the cancellous bone. The research is created in close cooperation with the Faculty of Dentistry, Semmelweis University, Budapest. The purpose of the study is to create a new, numerical bone modelling method that promotes the investigations of the bone tissue surrounding dental implants and – combined with finite-element modelling of screw-type implants – is applicable for simulating the mechanical behaviour of the cancellous bone. It should also produce mechanical properties comparable to that of the real bone tissue and should be capable of simulating the phenomena of load directed bone remodelling.

In the complex modelling process, besides the bone

modelling we aim at developing a method for the finite element modelling of screw

type dental implants, where geometric properties can arbitrarily be changed

according to the dental surgeon. We would like to combine the received screw

model with the cancellous and cortical bone and take into account the imperfect

connections between bone and implant, and thus determine the most appropriate

thread formation for different kinds of bone types.

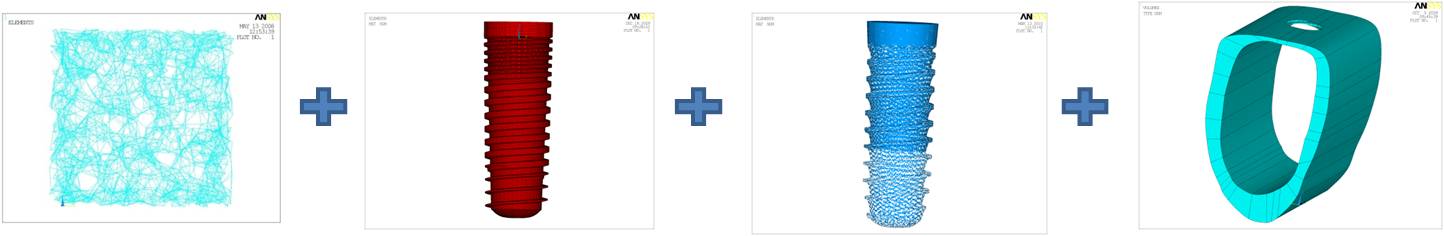

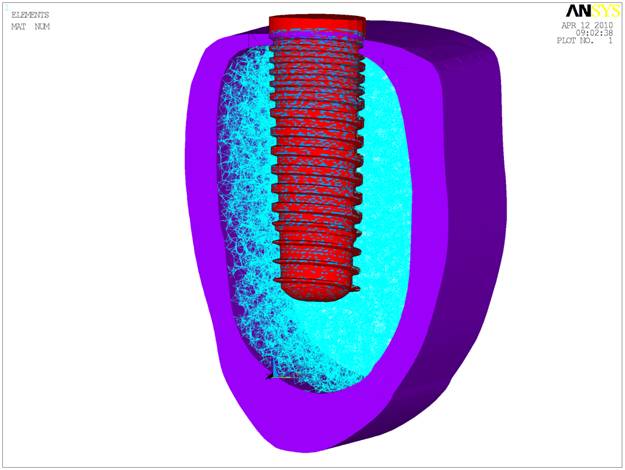

The complex modelling process can be divided into several steps: modelling the implant, the cortical and cancellous bone as well as the bone-implant interface and the imperfect connection and then compiling the whole model.

Modelling the implant:

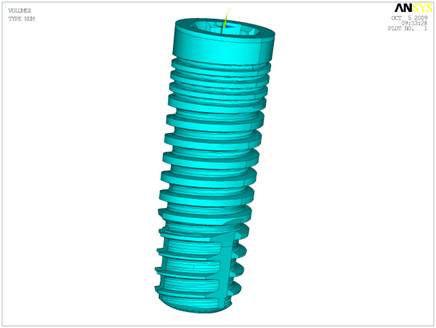

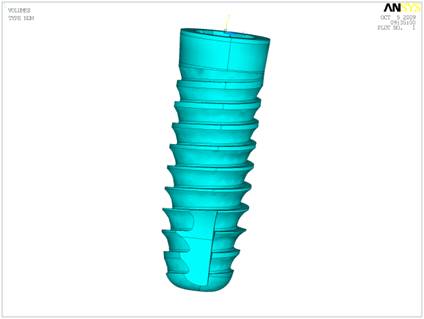

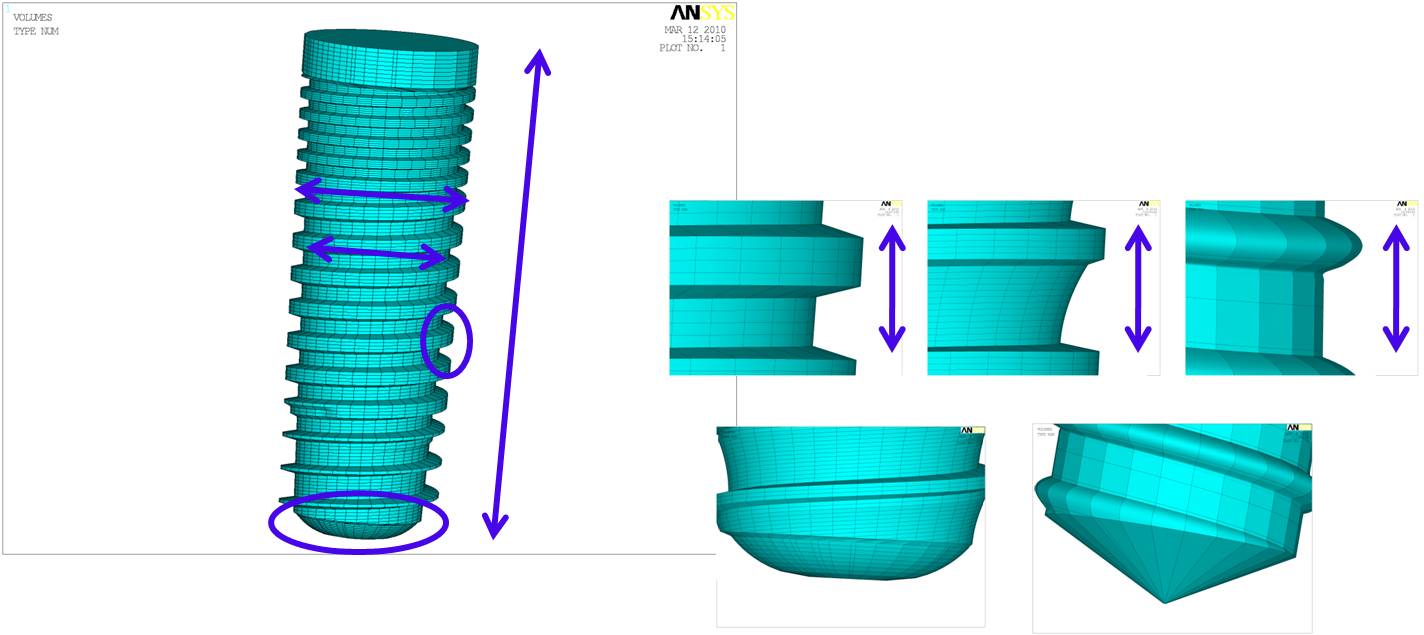

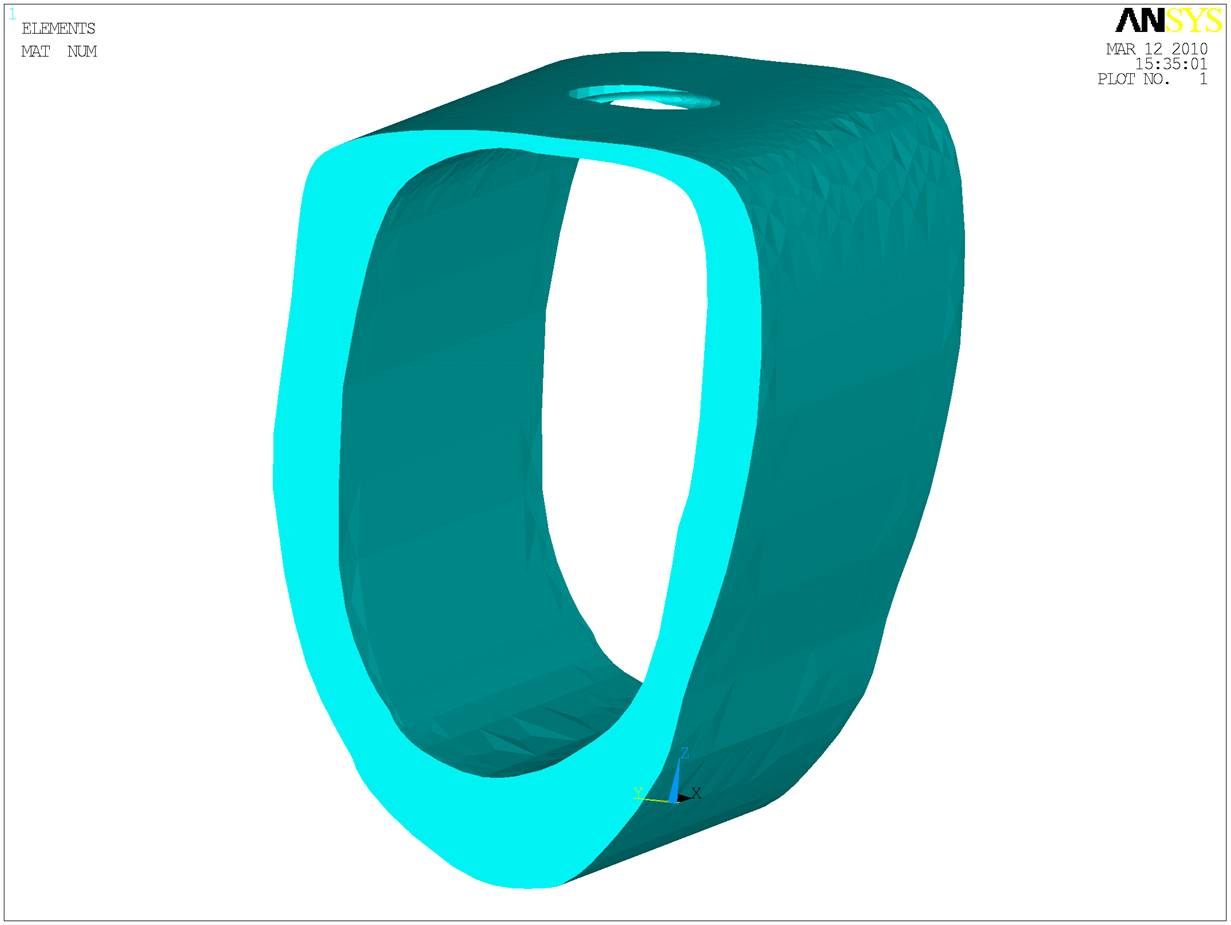

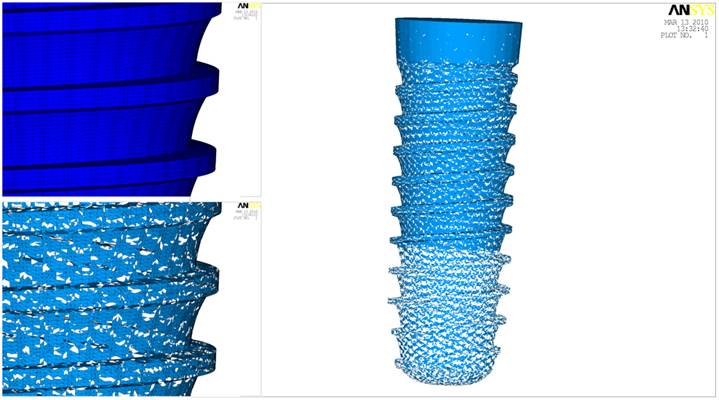

A method was developed for describing the geometry of the screw type implants by means of mathematical functions and several modifiable or revisable parameters to make the procedure of finite element modelling faster and easier. The parameters, which can be altered according to the sizes and shapes of the implants chosen by the dental surgeon, are the following: the length of the implant, the inner and outer diameters of the implant, the thread formation and thread pitch, all of which can change along the length according to a function or differ in certain segments and the shape of the implant apex.

Modelling the bone:

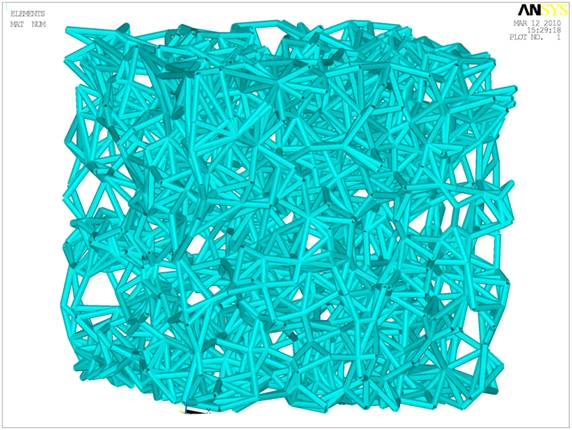

The porous structure of the trabecular (cancellous) bone

is taken into account by using a microstructural frame model, while the solid,

compact material of the cortical bone was considered as a homogeneous, linearly

elastic continuum. The finite element beam model of the cancellous bone was

created by interlinking a stochastically generated set of nodes in a certain

domain, according to a previously defined linking rule. Its geometric, material

and mechanical parameters can be revised according to the properties of the real

bone tissue.

Bone tissue, being a living biological material, is in a

state of continuous renewal and remodelling. The remodelling process leads to a

configuration of the trabeculae in the cancellous bone, which follows the

directions of the principal stress trajectories. For the purpose of simulating

the remodelling of the porous structure of the cancellous bone tissue its frame

model was used. In recent examinations a cube-shaped domain of the trabecular

bone was examined under compression and shearing as well as combined with a screw type bone implant.

Modelling the bone-implant interface:

At the bone-implant interface most of the finite element

models assume optimal osseointegration, which means that the bone is perfectly

bonded to the whole surface of the implant, which cannot be assumed during the

healing period and is strongly arguable after the complete healing because of the presence

of an intermediary layer between the two materials, which can be connected to

the implant surface in different degrees. The imperfection of the

osseointegration could be taken into account by modelling the aforementioned

intermediary layer as an imperfect membrane connecting the two

materials.

To make the everyday dental surgical design easier, we developed a method for the modelling of screw type dental implants, and we had the opportunity to try it in practice in the design of a new group of dental implants. The revisable parameters of the implant geometry (the length of the implant, the inner and outer diameters of the implant, the thread formation, the thread pitch and the shape of the implant apex) can be seen in the following figure.

In the finite element model of the trabecular bone introduced here (on the left), 4000 nodes were placed stochastically in a 5 mm x 5 mm x 5 mm cubed domain, each linked to its 7 closest neighbours. As a result, in the finite element model each trabecula is represented by one beam element. The model of the cortical bone can be seen on the right.

For the simulation of the load dependent bone remodelling process two different methods have been developed: one that gives an ideal configuration to a given load and another being capable of following the loading process and altering the bone structure accordingly. The following three animations show the development of the frame model according to the first algorithm, where the trabeculae arisen from compression are signed in red and the ones from tension in blue colour.

Bone

remodelling – compression Bone

remodelling – shearing Bone

remodelling – around an implant

A method was developed for connecting the desired percentage of bone

and the implant surface by means of an intermediary membrane covering different

percents of the surface of the implant (in the present example 30% at the apex,

60% in the middle, where it meets the trabecular bone and 90% at the upper

region of the implant, where the membrane meets the cortical bone).

From the above expanded parts we compiled the finite element model of the screw type dental implant placed in the lower-jawbone. In the present stage of the research the model is being tested and the effect of the varying geometric and material properties is being examined.

Within the frameworks of my PhD studies a new finite

element modelling method has been developed for the modelling of screw type

dental implants. The possibility for the fast and easy modification of the

geometric properties helps the design and development of dental implants. Our

new method for generating computer models for screw implants is effectively

utilized in the design of an implant group, which is currently under design and

is intended to be applied in everyday dental surgery.

Currently the complex model of the implant and the jaw bone is examined.

The impact of the different (geometric, material and mechanical) properties of

the bone and the implant on their mechanical behaviour is being determined.

According to the results of these examinations our final aim is to develop a

method for determining the most appropriate implant geometry to bone structures

with different anatomical properties.

List of publications:

Lakatos É.: The Biomechanical Behaviour of the Human Jaw-bone, Seminar of

the BME Department of Applied Mechanics and Department of Structural Mechanics,

Budapest, 2007

Lakatos É., Bojtár I.: The Biomechanical Behaviour of the

Trabecular Bone Surrounding Dental Implants, 3rd Hungarian Conference on

Biomechanics, Budapest, 4–5 July 2008, pp. 159–167 open

article

Lakatos É., Bojtár I.: Stochastically Generated Finite

Element Beam Model for Dental Research, 17th Inter-Institute Seminar for Young

Researchers, Cracow, Poland, 22–23 May 2009, pp. 9.

Lakatos É., Bojtár

I.: Stochastically Generated Finite Element Beam Model for Dental Research,

Periodica Polytechnica Ser. Civ. Eng., 53 (1) pp.3–8. (2009) open

article

Lakatos É., Bojtár I.: Stochastically Generated Finite

Element Beam Model of the Trabecular Bone Surrounding Dental Implants,

International Conference on Tissue Engineering. Leiria, Portugal, 9–11 July

2009, pp. 257–264 open

article

Lakatos É., Bojtár I.: Algorithms for simulations of the

trabecular bone remodelling by means of a stochastically generated finite

element frame model, Journal of Biomechanics (submitted for

publication)

Lakatos É., Bojtár I.: A Szivacsos Csont Átalakulásának

Modellezése Sztochasztikusan Generált Keretmodell Segítségével, (Modelling of

the remodelling of cancellous bone by means of a stochastically generated finite

element frame model), Biomechanica Hungarica, 3 (2), (2010)

(accepted)

Lakatos É., Bojtár I.: Microstructural simulations of the bone

surrounding dental implants by means of a stochastically generated frame model,

4th Hungarian Conference on Biomechanics, Pécs, 7–8 May 2010, Biomechanica

Hungarica, 3 (1) pp. 143–150. open

article

Lakatos É.: A szivacsos csont mikroszerkezetének végeselemes

keretmodellje és alkalmazása a szájsebészetben (A finite element frame model of

the trabecular bone and its dental surgical applications), Seminar of the BME

Department of Applied Mechanics and Department of Structural Mechanics,

Budapest, 2010

Useful links:

Budapest University of Technology and Economics

Department of Structural Mechanics

Hungarian Society of Biomechanics

Bone

Journal of

Oral Implantology