|

BMe Research

Grant |

|

Pattantyús-Ábrahám Géza Doctoral School

Department of Polymer Engineering

Supervisors: Dr. Péter Nagy and Dr. László Oláh

Development of polymer-based implant materials for bone tissue engineering

Introducing the research area

During my PhD studies I investigated scaffolding materials for bone tissue engineering. The aim of such implants is to promote the regeneration instead of replacing the damaged tissue. After implantation, the scaffolds restore the main functions of host tissue, support the cell adhesion and proliferation. Parallel to the tissue remodeling, the implant material degrades and the degradation by-products metabolize out from the body.

Brief introduction of the research place

My work was carried out at the Department of

Polymer Engineering. Our department focuses on high quality work and research.

As a result, it was the first university unit in Hungary to introduce the

ISO 9001 Quality Management System in 2002. In 2004, the NAT (National

Accrediting Committee) also accredited our laboratory. The high-standard work is

reflected in the number of international publications, cooperations as well as

in the quality of our own journal. The eXPRESS

Polymer Letters is published by the department and is indexed by several

organizations, among others Thomson Reuters and Scopus. Its impact factor in

2010 is 1.575.

History and context of the research

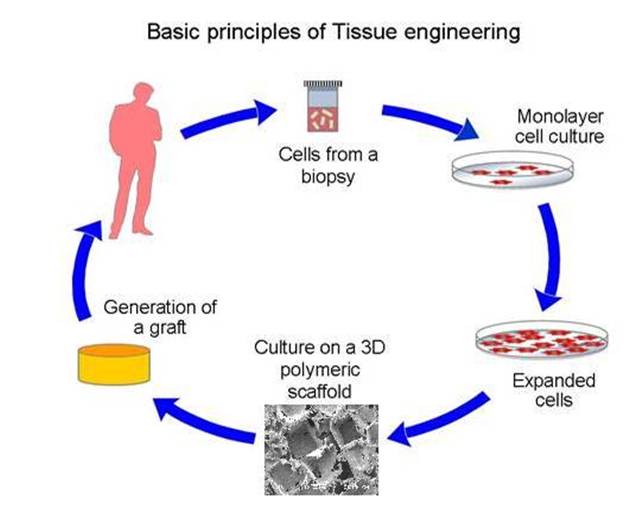

Tissue engineering (see scheme on the right), the restoration of the main

function of lost tissue is not a completely new idea. Studies in this topic were also

conducted in the early '80s. Moreover, skin reconstruction techniques developed at

that time are now in clinical use.

Tissue engineering (see scheme on the right), the restoration of the main

function of lost tissue is not a completely new idea. Studies in this topic were also

conducted in the early '80s. Moreover, skin reconstruction techniques developed at

that time are now in clinical use.

During the '90s a significant progress was made. The 2D cell cultures turned into 3D and the dimensions of scaffolds also increased [1]. Ever since, a number of materials, manufacturing methods and cell transplantation techniques were exposed. However, neither of them could meet all the requirements. The perfect method has not been invented yet.

The main functions of implant are to replace temporarily the role of lost tissue and to support the regeneration. For this purpose, adequate mechanical performance as well as bioactivity are needed. During the material selection the utmost important criterion is the biocompatibility, namely the compatibility with living tissues and organs. Since degradable polymers and ceramics are used, the degradation by-products should not elicit toxic materials or chronic inflammations.

The current in vivo and clinical experience have also pointed out that the main problems with biodegradable polymeric implants are the pH decrease in the surroundings of implant and the fragmentation of scaffolding material. The latter could generate post-operative problems after up to 5-7 years as well. Additionally, during bone remodeling, the small fragments could cause repeated inflammation and pain [2].

During the development of

scaffold manufacturing methods, techniques optimized for the processing of

individual or short series products were favored. This resulted in the

appearance of Rapid Prototyping technologies. The concept was to create implants

in one step based on a CAD model derived from CT (computer tomography) images.

The product could be either an implant or the underlying tool [3].

The research goal, open questions

The main aim of my research is to prepare tailored scaffold materials for bone tissue engineering. The implant should meet requirements similar to the properties of cancellous bone and support its load-bearing role for a period of 3-6 months. The gradual loss of implant properties necessitated the determination of degradation kinetics, as well. The deterioration of mechanical properties was, therefore, monitored on 3D scaffolds in vitro. Among the mechanical properties I paid special attention to the fracture mechanical behavior. The fragmentation of implant could be prevented by increased material toughness. As a result, the post-operative, late degradation inflammations could be avoided. In my study the manufacturing methods of individual, tailored implants and biocompatibility-related topics were also investigated.

Methodology

Applied materials

In my experiments biocompatible polymers (poly-ε-caprolactone, poly-D,L-lactide, lysine-isocyanates) and different salts (calcium-carbonate, β-tricalcium-phosphate) were used.

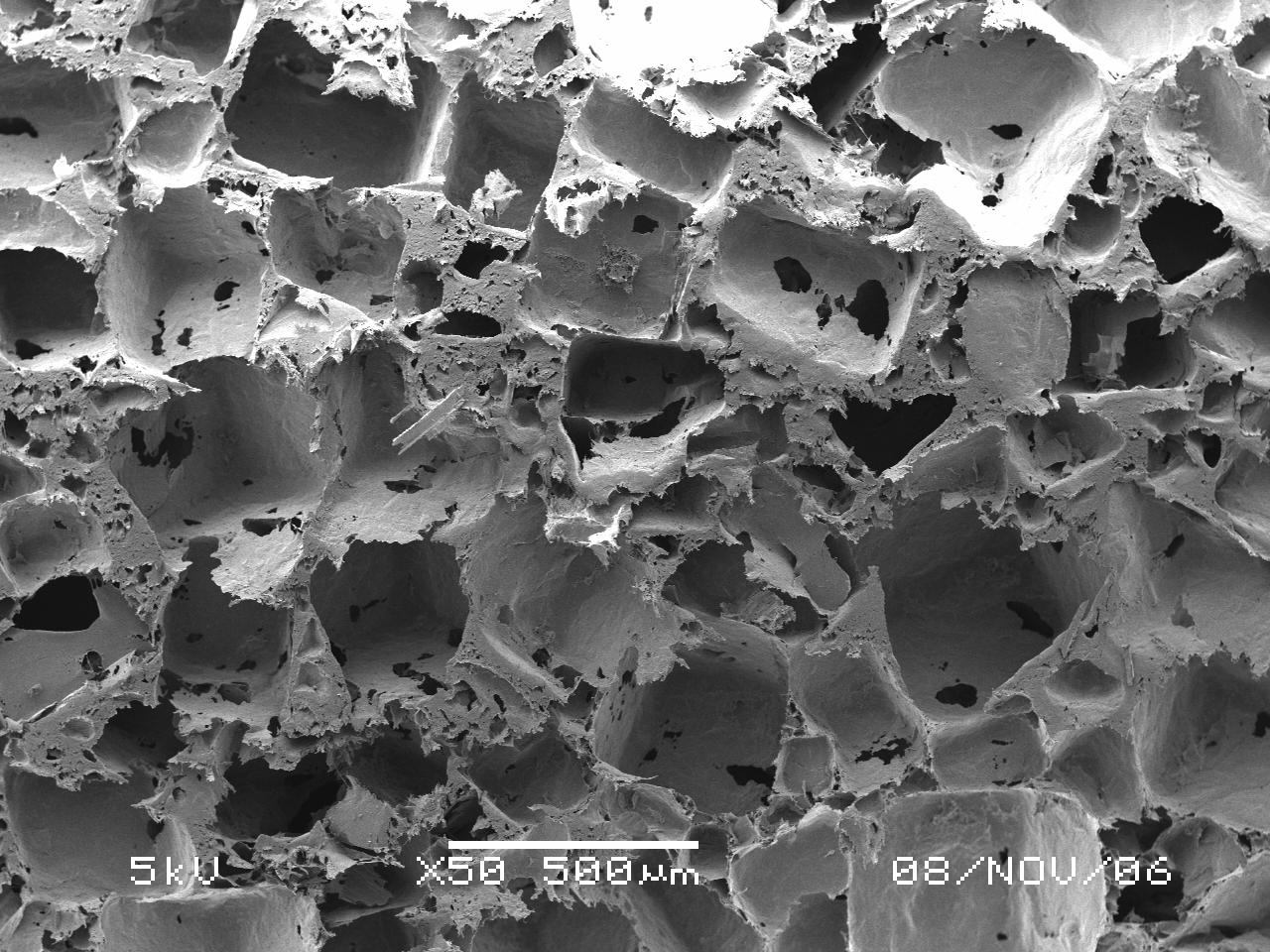

Preparation of scaffolds

After melt blending the scaffolds (see figure on the right) were prepared by hot-pressing. The porous structures were fabricated by melt-blending/particulate-leaching technique. Sodium-chloride was used as pore forming agent. After manufacturing, sodium-chloride could easily be leached out of the implant. Over 70% of salt content the scaffold has interconnected structure [4]. This form favors the ingrowth of cells into the implant and the application of toxic materials could also be avoided by using this manufacturing method.

Mechanical tests

The mechanical properties of examined materials

were characterized by quasi-static compression and tensile tests as well as by

fracture mechanical measurements. Since the applied polymers showed high

plasticity, the theories of linear-elastic fracture mechanics could not be

applied. For the characterization of fracture behavior the Essential Work of

Fracture (EWF) method was used. The basics of this concept are simple. It

separates the work performed within the plastic zone into a work required for

the formation of newly cracked surfaces – essential work of fracture term – and

into a work dissipated in the plastic zone – plastic or non-essential work of

fracture [5].

Fabrication tailored implants

The variation of medical cases calls for a cheap

and rapid manufacturing method of individual implants. The fabrication of such

implants was performed by a novel methodology. The concept is based on prior

methods, which used CT images to create the model of implant, and rapid

prototyping (RPT) techniques to fabricate the scaffold. In this study the mold

was prepared by RPT methods – this technique is called Rapid Tooling – and the

implant was formed by compression molding. During the development different

techniques were tested. 3D printers and Objet technique were also used. As a

result, the manufacturing process is fast – 1-2 days for dense implants and 1-2

weeks for porous scaffolds – and the prepared tools are much cheaper compared to

the conventional steel ones.

Degradation and biocompatibility studies

The degradation kinetics of applied polymers and

scaffolds were analyzed in vitro – under laboratory circumstances, at

37°C and in phosphate puffered saline. The effect of hydrolysis had been monitored

for two years. Structural, pH and mechanical property changes were studied. Cell

adhesion and proliferation studies were performed in cooperation with Semmelweis University 1st

Department of Pathology and Experimental Cancer Research Institute. The cell

ingrowth was analyzed in the Laboratory

of Experimental Gene Therapy of OVSZ (Hungarian National Blood Transfusion

Service).

Results

First, I would like to present my results relating

to the compatibilization of poly-ε-caprolactone/poly-D,L-lactide blends.

Subsequently, I deal with the composites filled with bioactive ceramics. Finally,

the results relating to the preparation of molds with Rapid Tooling are

presented along with the in vitro degradation and biocompatibility

tests.

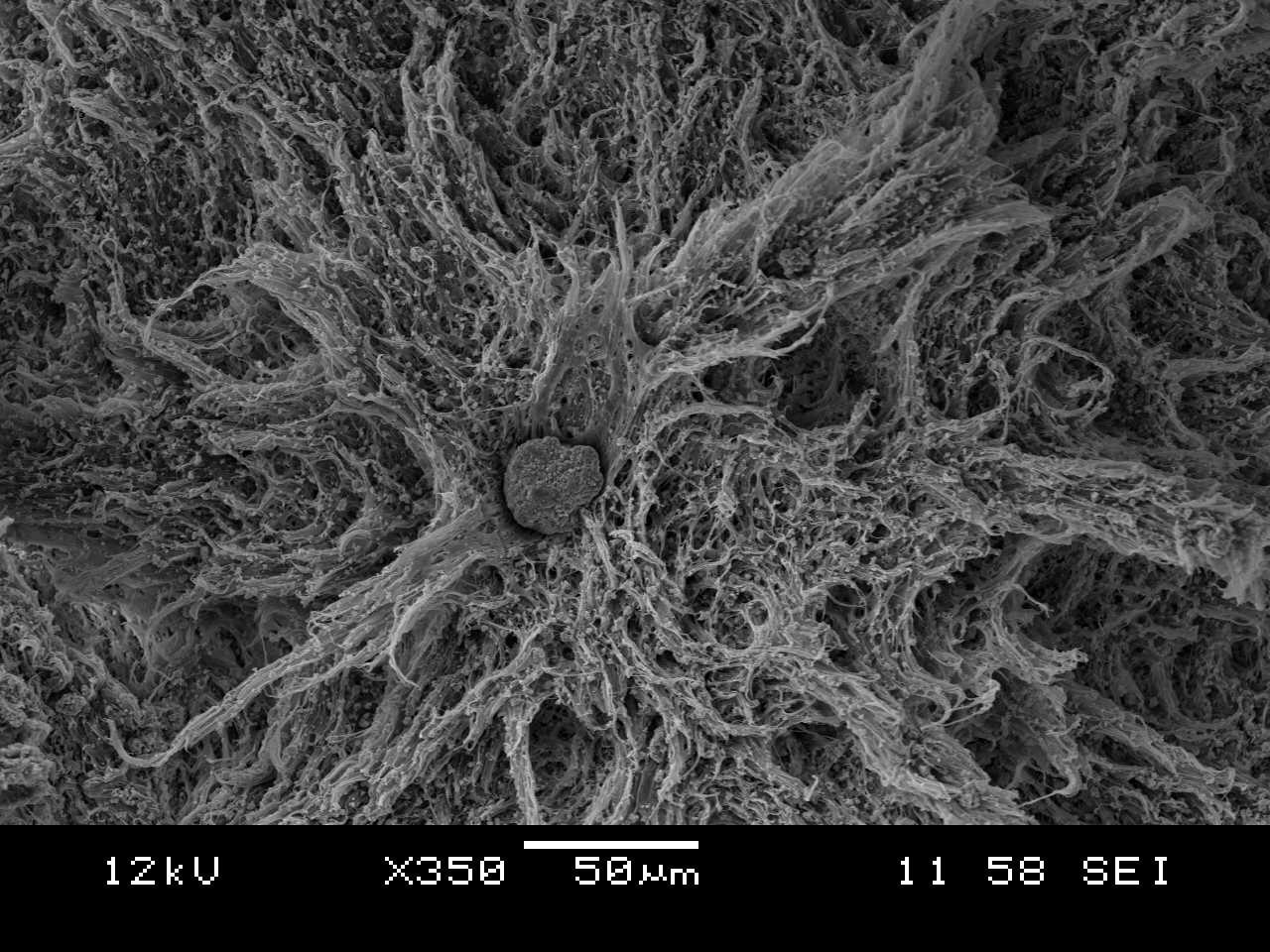

Biocompatible polymer blends

In the blends I

would like to combine the toughness of poly-ε-caprolactone with the higher

strength and modulus of poly-D,L-lactide. These two polymers are, however,

immiscible and their blends have inferior mechanical properties. The weak

interphase in the dispersed morphology cannot retard the crack propagation and,

as a result, the failure moves through these weak regions (see figure on the

left).

In the blends I

would like to combine the toughness of poly-ε-caprolactone with the higher

strength and modulus of poly-D,L-lactide. These two polymers are, however,

immiscible and their blends have inferior mechanical properties. The weak

interphase in the dispersed morphology cannot retard the crack propagation and,

as a result, the failure moves through these weak regions (see figure on the

left).

To improve the compatibility of the two phases,

reactive lysine-isocyanates were added to the system. Despite the small amounts

of compatibilizer (0.5 phr) the toughness increased significantly. The surface

stress, and as a result, the size of droplets decreased. The increase in fracture

resistance was prominent; in certain blends the essential work of fracture

nearly doubled.

Bioactive composites

Composites containing poly-ε-caprolactone or

poly-ε-caprolactone/poly-D,L-lactide as matrix material and calcium-carbonate

and/or β-tricalcium-phosphate as reinforcement were also prepared. The goal in

these materials was to increase the mechanical strength and biocompatibility,

while maintaining adequate toughness. The effect of filler content and shape

(calcium-carbonate in the form of spherical calcite and needle-like aragonite)

was analyzed. Both calcium salts increased the compressive and tensile strength,

and the mechanical properties of cancellous bone were also attained.

Nevertheless, the filler content has an upper limit. The formed aggregates

(see figure on the right) demolish the material toughness.

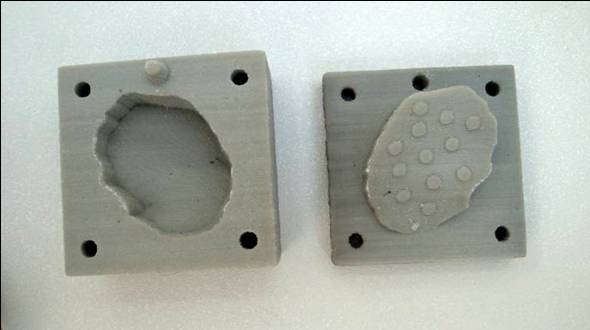

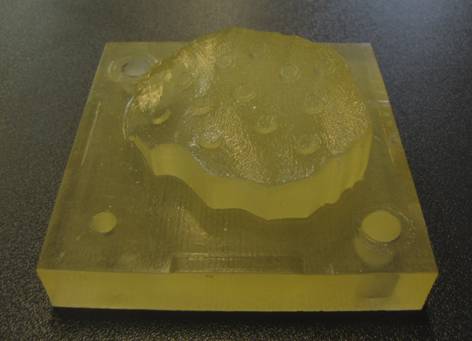

Manufacturing of individual implants by Rapid

Tooling

The base materials were hot pressed in individual

tools to form implants with multiple curvature. The mold was manufactured by a

3D printer and an Objet apparatus (Figure 1) from the same 3D CAD model (the

base of this model was a former CT image), respectively. Both tools permitted

the preparation of poly-ε-caprolactone based scaffolds; however, the latter

technique facilitated opening the mold and the product removal. After compression

molding, to attain porous scaffolds, the salt was leached out from the implant

in two weeks.

Figure 1: Molds fabricated by 3D printing and Objet technology as

well as the finished polymer implant

In vitro degradation studies

The degradation studies supported the hypothesis

that the hydrolysis of amorphous phase is faster than that of the crystalline parts.

This was demonstrated at certain time intervals with the increasing

crystallinity of samples. This process could be explained by the differences in

diffusion properties. The compressive strength and toughness of samples have also

deteriorated parallel to the decrease in average molecular weight. Differences

were observed between the degradation kinetics of porous and dense scaffolds.

This could also be correlated with the variation of diffusion

characteristics.

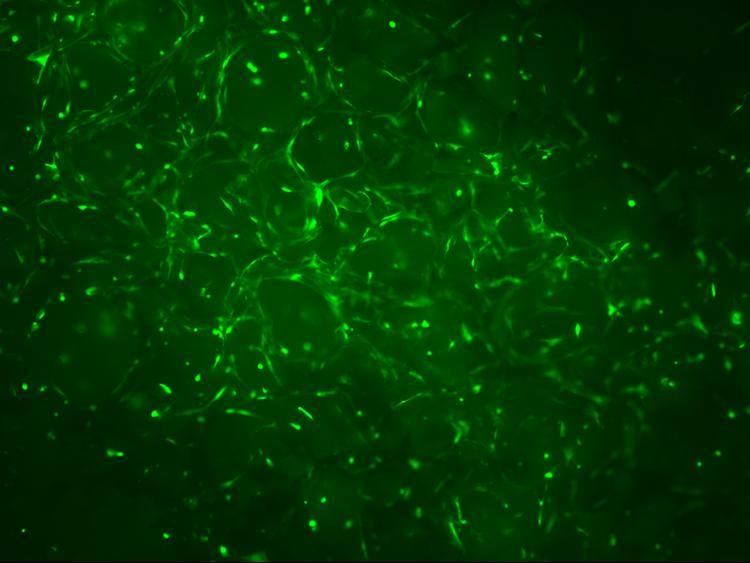

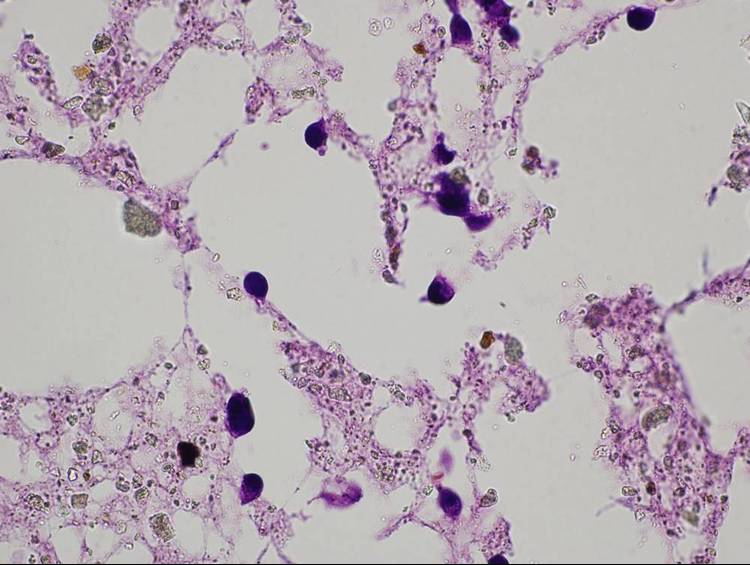

Biocompatibility tests

The bioactivity of calcium-carbonate salts was demonstrated with cell counting measurements. The cell adhesion on sample surface and the proliferation parameters increased with calcium-carbonate content. The reasons for this were the more hydrophilic surface of implant and its ability to stabilize the pH decrease resulting from the degradation of polymers.

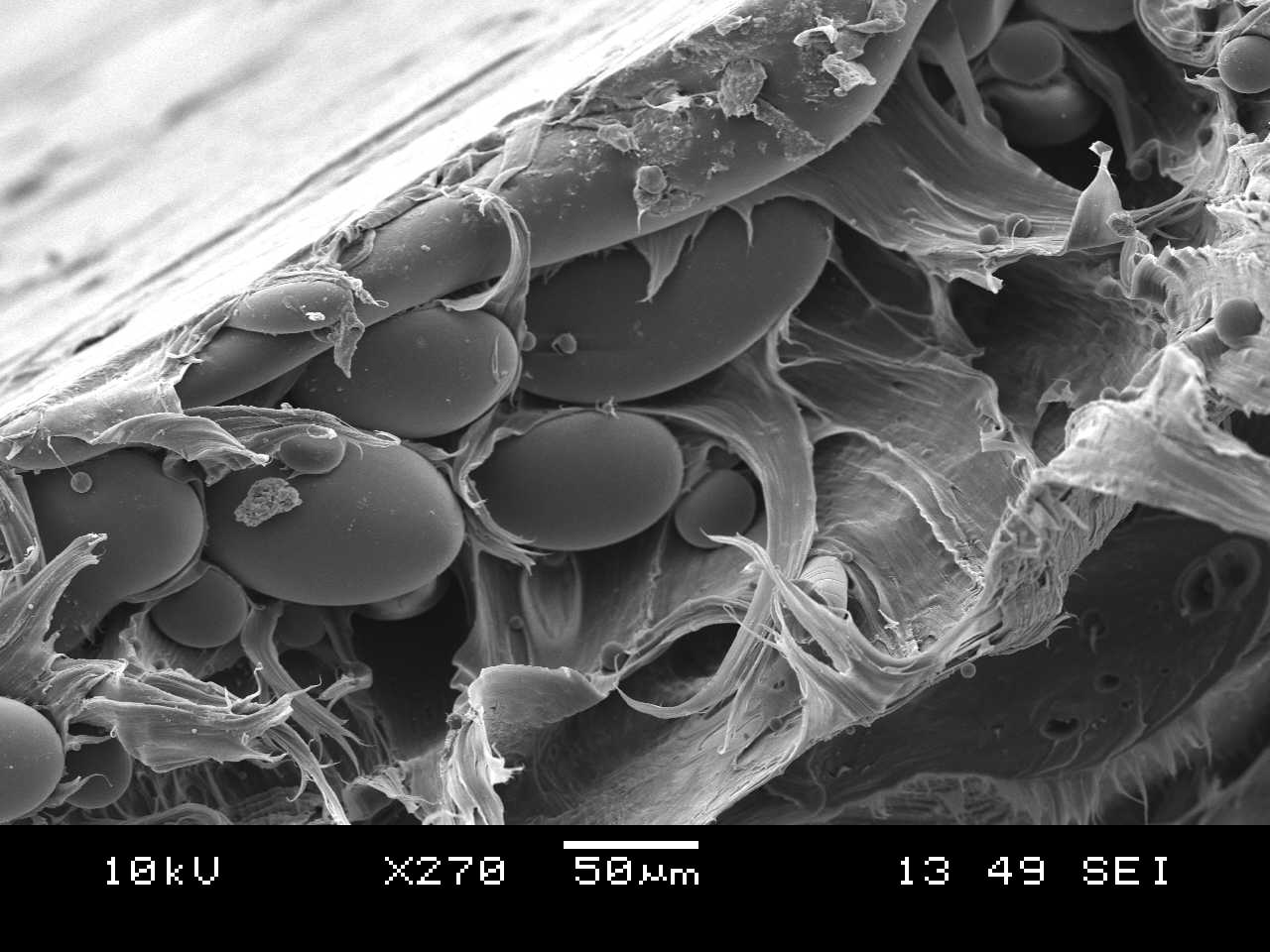

The cell ingrowth was promoted in porous

scaffolds (Figure 2). This indicates that the prepared foams have interconnected

structure, and the pore size is large enough to allow cell ingrowth. The

fabrication of large cellular systems is, however, hindered due to the poor

vascularization and nutrition of inner regions.

Figure 2: Cells in the pores of a scaffold (Fluorescent microscopic images with a magnification of 4x and 60x)

Expected impact and further research

I have prepared biocompatible polymer blends and composites, which have adequate properties to support major injuries in cancellous bone. These polymer blends of increased toughness can arrest the fragmentation of implants. Consequently, the embedding of small particles and late degradation inflammation can be avoided. Composites filled with bioactive ceramics can lower the post-operative inflammations caused by degradation by-products.

In the future I would like to combine the

toughness of blends with the bioactivity of composites. I plan to extend the

in vitro degradation and biocompatibility tests. In cooperation with

other research groups we may perform in vivo experiments, as

well.

Publications, references, links

Publications

Tuba F., Oláh L., Nagy P. Characterization of reactively compatibilized poly(D,L-lactide)/poly(ε-caprolactone) biodegradable blends by essential work of fracture method. Engineering Fracture Mechanic, (accepted with revisions)

Tuba F., Oláh L., Nagy P. Essential work of

fracture study of polymers – a novel criterion for the validation of tested

ligament range. Journal of Materials Science (accepted with revisions).

Tuba F., Oláh L., Nagy P. Characterization of fracture properties of aragonite and calcite filled poly(ε-caprolactone) by essential work of fracture method, Journal of Applied Polymer Science, 120(5), 2587-2595 (2011)

Oláh L., Tuba F. Investigation of calcium carbonates enhanced poly(ε-caprolactone) materials for biomedical applications. Macromolecular Symposia, 296(1), 371-377 (2010)

Szenti A., Tuba F., Kovács N. K. Rapid Tooling technologies in the processing of thermoplastic polymers. Materials Science Forum, 659, 97-102 (2010)

Tuba F., Borbás L., Nagy P., Oláh L. Hydrolysis induced deterioration of compressive properties of poly(e-caprolactone). FME Transactions, 37(1), 33-37 (2009)

Tuba F., Borbás L., Oláh L., Hadzima B. Development of polymer based scaffolds for guided tissue regeneration. Proceedings of the Third Hungarian Conference on Biomechanics (ISBN 978 963 06 4307 8), 379-386 (2008)

Tuba F., Oláh L. Development of polymer based biodegradable scaffolds for bone tissue regeneration – in Hungarian. Műanyag és Gumi, 44(4), 171-174 (2007)

References:

[1] Vacanti J.P., Langer R. Tissue engineering:

the design and fabrication of living replacement devices for surgical

reconstruction and transplantation. The Lancet, 354, S32-S34 (1999)

[2]

Bergsma J.E., de Bruijn W.C., Rozema F.R., Bos R.R.M., Boering G. Late

degradation tissue response to poly(L-lactide) bone plates and screws.

Biomaterials, 16, 25-31 (1995)

[3] Manó S., Novák L., Csernátony Z.

Application of 3D printing in cranioplasty – in Hungarian. Biomechanica

Hungarica, 1, 15-20 (2008)

[4] Oláh L., Filipczak K., Jaegermann Z., Czigány

T., Borbás L., Sosnowski S., Ulanski P., Rosiak J.M. Synthesis, structural and

mechanical properties of porous polymeric scaffolds for bone tissue regeneration

based on neat poly(ε-caprolactone) and its composites with calcium carbonate.

Polymers for Advanced Technologies, 17, 889-897 (2006)

[5] Bárány T., Czigány T., Karger-Kocsis J. Application of the essential work of fracture (EWF) concept for polymers, related blends and composites: A review. Progress in Polymer Science, 35, 1257-1287 (2010)

Links: