|

|

BMe Research Grant |

|

Géza Pattantyús-Ábrahám Doctoral School of Mechanical Engineering

Department of Mechatronics, Optics and Engineering Informatics

Supervisors: Prof. Dr. habil György Ábrahám and Dr. Géza Haidegger

New methods in sheet-based Rapid Prototyping

Introducing the research area

My research topic is the analysis and improvement of a new kind of plastic deformation process, the so-called Incremental Sheet Forming (ISF). My goals include the analysis and improvement of this new kind of plastic deformation process, furthermore, the modelling, development and testing of new measurement methods for ISF which can make the sheet forming more accurate and effective. During my research, I touched a number of subtopics of the area, such as tool path calculation procedure, sensor integration and adaptive control.

Brief introduction of the research place

I carried out my research work at BME Department of Mechatronics, Optics and Engineering Informatics and at the Computer and Automation Research Institute, Hungarian Academy of Sciences, Computer Integrated Manufacturing Laboratory.

Both institutions conduct applied research on Incremental Sheet Forming

and their laboratories are well-equipped to ensure high quality work.

History and context of the research

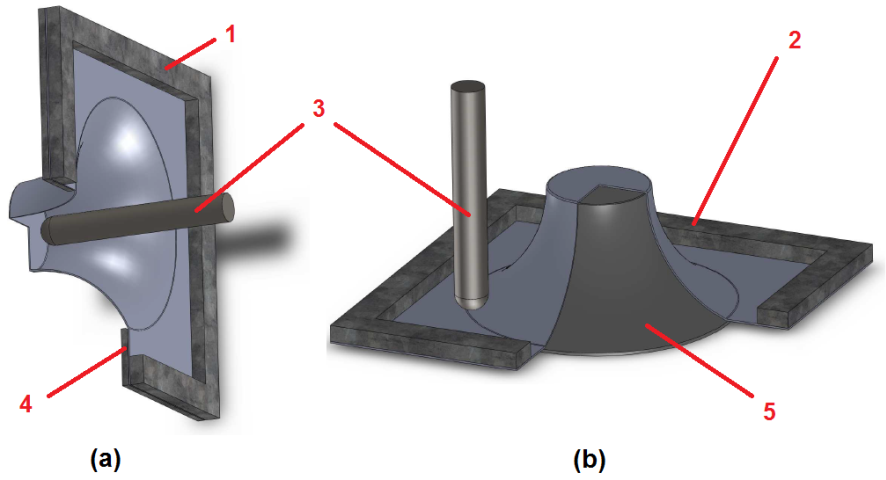

The ISF process is similar to metal spinning which dates back to a patent granted in 1967 [1]. However, unlike metal spinning, where the sheet metal is formed on a lathe to an axial symmetric object by rotating and continually pressed it with a tool, in ISF, the sheet is clamped down with a frame and formed with a tool ending in spherical head. In contrast to conventional plastic deformation processes, the final shape of the workpiece is not determined by a specific die, but by the three-dimensional movement of a "universal" forming tool, for which an appropriate tool path has to be established, based on the workpiece geometry. This movement can be carried out by a CNC milling machine or by an industrial robot, but sheet forming can also be achieved by moving the clamping frame [2]. Figure 1 shows the main variants of this process.

Figure 1. Illustration of (a) vertical SPIF, (b) horizontal TPIF with

1: stationary blank holder (BH),2: moving BH, 3: forming tool,

4: backing- /faceplate,5: stationary/moving, full/partial die

The

design, manufacture and later on the storage/disposal costs of a

traditional stamping tool are significantly higher than those in ISF, which

allows higher formability and is more environment-friendly. Of

course, this relatively slow process is only profitable for small

series and rapid prototypes but it finds different applications in automotive and aircraft industries, in architecture

engineering and in medical aids manufacturing. In the past two decades,

ISF research focused on the boundaries, on process modelling, on the improvement of the geometric accuracy of workpieces,

on the applicability of new materials, and on tool path

optimization.

The research goal, open questions

My research targets the technological development of Incremental Sheet Forming.

Since,

according to the literature and based on experiences, the numerical

simulation of processes is time consuming [3], I

attempt to test and compare new machining strategies with forming

experiments. To avoid sheet fracture in this procedure, it is important to determine indirectly or

directly the sheet thinning. Direct measurement methods are preferable for anisotropic

sheets. The open questions are: what type of direct measurement method is

suitable for sheet thinning [4] and how to intervene in the machining

process. A further question is related to the definition and application of optimal tool path in terms of workpiece quality, and to the implementation of

adaptive control.

Methods

In the investigation, aluminium (Al1050), PVC and PE-HWST sheets were used. Tensile tests were performed to determine the characteristics of certain sheets. Both Design of Experiments method (DoE) and ANOVA analysis were used in the research work.

Applied equipment:

- Rieckhoff type 2.5D CNC milling machine

- Prototype of a TSISF system

- Mitsubishi RM-501 type manipulator

- KUKA KR6 type industrial robot

- FANUC S430iF type industrial robot

Force measurements were carried out with a JR3 type Multi-axis force and torque sensor cell. Some sample parts are scanned with GOM’s systems, sheet thickness measurements have been validated with a Mitutoyo SLIM Type Linear Gage.

The integration of Hall sensor (AD22151 type IC - for thickness measurements) into the ISF process was carried out with the help of a self-made calibration device based on a micrometer screw. Preliminary simulations and the design of the sheet thickness measurement device alpha prototype were carried out with a FEM program.

Results

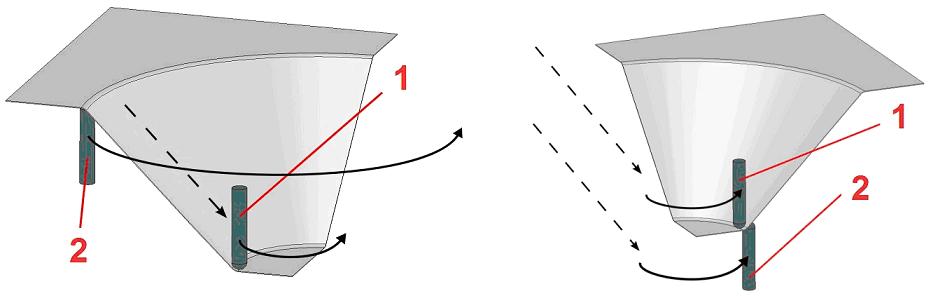

I improved the supporting tool path calculation algorithm [P1] used in a new incremental forming process [P2-P5]. Two main forming strategies are known (strategy "A" and "B" - see Figure 2) in case of Two Point Incremental Forming with moving supporting tool. In case of strategy "A" the supporting tool is acting as a faceplate, moves with the forming tool, but does not leave the starting plane of the supporting tool path. In case of strategy "B" the supporting tool moves with the forming tool, ensuring continuous support. Experiments proved that with aluminium (Al 1050) sheets strategy "B" results in better formability than strategy "A" [P7]. This result was later confirmed by independent scientific works too [5].

Figure 2. Forming strategy „A” and „B”

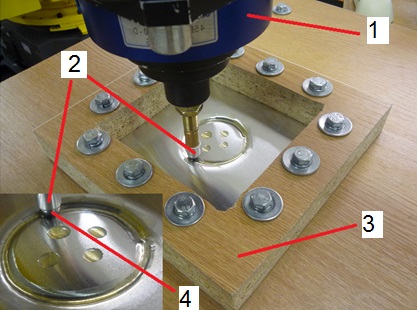

1: forming tool, 2: supporting tool

Sheet thinning during the ISF, contraction (contraction of local cross-section) and the resulting fracture are serious problems. To solve these problems, I proposed an integration of a Hall-sensor in the forming tool [P6] and an inverse version of it [P8], [P10], which can be applied to non ferromagnetic sheets and can easily be connected to various controllers. Finite element method was used in the development of the first version of this equipment and experiments were carried out to validate a prototype. I have also developed an adaptive control algorithm based on thickness measurement, which allows switching between the different tool paths [P8] (the experimental set-up is shown in Figures 3 and 4).

Figure 3. ISF of aluminium sheet (Al1050, sheet thickness: 0.5 mm), where

1: Force cell, 2: tool holder, 3: clamping frame, 4: forming tool (metal ball)

Figure 4. Experimental set-up (view from below), where 1: Hall-effect sensor for thickness measurement with permanent magnet, 2: non-ferromagnetic faceplate

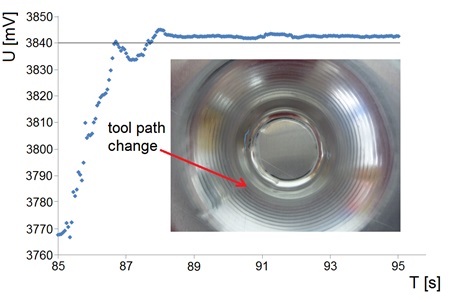

The magnetic field changes with changing thickness (in this case, the distance between the forming tool and the Hall-sensor with magnet).

With the help of a “distances - Hall-voltage” calibration curve the corresponding thickness can be determined and for the predefined critical thickness value, a tool path with smaller (finer) incremental depth can be assigned.

Figure 5 shows the result of the continuous measurement and the location of tool path change at the critical value.

Figure 5. Measurement result with Hall-sensor and photo of the formed part

with changed tool path

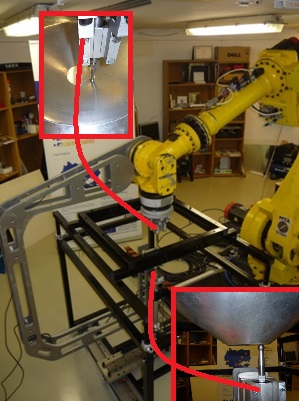

I planned a mechanical copying device with more variants, which simplifies the control of the Two Point Incremental Forming with moving supporting tool, while sharing the load with the process [P9], [P11], [P12]. Figure 6 shows a picture of the realised prototype (image insets illustrate the ISF process from both sides).

Figure 6. Prototype of the two-sided incremental sheet forming system with a FANUC S430iF type industrial robot

The

application is patented in the EU (EP 11462004.0 – “Device for

two-sided incremental sheet forming”), with Prof. János Somló and me as co-inventors.

Expected impact and further research

The integrated thickness measurement device allows continuous quality control and can reduce rejects. The patented device allows high-speed two-sided incremental sheet forming in a cost-effective (nearly 50% saving on investment and operating costs) process. In my further research I plan to combine 3D printing with the heat-assisted incremental forming of thermoplastic polymer sheets.

Publications, links, references

Publications:

[P1] Paniti I, Kovács G, Haidegger G (2007): Mechatronikai rendszer prés-szerszámnélküli lemezalakításhoz (in Hungarian), GÉP 58, pp. 21-23.

[P2] Paniti Imre (2008): Designing tool path generating strategies for novel Incremental sheet forming, X International PhD Workshop, OWD 2008, Vol. 25, 2008.10.18-21., pp. 142-146.

[P3] Imre Paniti (2010): CAD API based tool path control for novel incremental sheet forming, POLLACK PERIODICA 5 (2), pp. 81-90., DOI:10.1556/Pollack.5.2010.2.8

[P4] János Nacsa, Imre Paniti, Sándor Kopácsi (2011): Incremental Sheet Forming in Cyberspace - a Process Oriented Cognitive Robotics Application, 2nd International Conference on Cognitive Infocommunications, CogInfoCom 2011, Budapest, Hungary 2011.07.07-09, pp. 1-5.

[P5] Paniti Imre, Haidegger Géza (2007): Control development for mechatronic sheet metal forming processes, MicroCAD 2007 International Scientific Conference. Miskolc, Hungary, March 22-23, 2007, pp. 207-212.

[P6] I. Paniti, A. Paróczi (2011): Design and modelling of integrated Hall-effect sensor based on-line thickness measurement device for incremental sheet forming processes, Processing of the 2011 IEEE/ASME International Conference on Advanced Intelligent Mechatronics (AIM), pp. 297-302., DOI:10.1109/AIM.2011.6027146

[P7] M. Tisza, I. Paniti, P. Z. Kovács (2010): Experimental and numerical study of a milling machine-based dieless incremental sheet forming, International Journal of Material Forming, Volume 3, Supplement 1, 2010, pp. 441-446., DOI:10.1007/s12289-010-0931-9

[P8] Paniti, I. (2014): Adaptation of Incremental Sheet Forming into cloud manufacturing, CIRP Journal of Manufacturing Science and Technology, 7 (3) pp. 185-190., DOI:10.1016/j.cirpj.2014.04.003

[P9] Paniti, I. (2014). A novel, single-robot based two sided incremental sheet forming system, In Proceedings of the 45th International Symposium on Robotics (ISR 2014) and the 8th German Conference on Robotics (ROBOTIK 2014), Munich, Germany, June 3 - 6, 2014, pp. 547-553.

[P10] Paniti, I. (2014). New Solutions in Online Sheet Thickness Measurements in Incremental Sheet Forming. In Applied Information Science, Engineering and Technology, Springer International Publishing, pp. 157-177., DOI:10.1007/978-3-319-01919-2_9

[P11] Paniti, I. and Somló, J. (2014): Novel incremental sheet forming system with tool-path calculation approach, Acta Polytechnica Hungarica, 2014 , DOI: 10.12700/APH.11.07.2014.07.3, Vol. 11, No. 7 IF=0.588.

[P12] Paniti, I., and Somlo, J. (2013): Device for two sided incremental sheet forming, EU Patent EP2505279

Links:

Incremental Sheet Forming course in the topic: "High-tech machine Industry" (in Hungarian language)

http://www.mti.bme.hu/tanfolyam/05-006.html

Incremental Sheet Forming on Wikipedia

http://en.wikipedia.org/wiki/Incremental_sheet_forming

References:

[1] Emmens, W.C. and Sebastiani, G. and Boogaard van den, A.H. (2010) The technology of Incremental Sheet Forming - a brief review of the history. Journal of Materials Processing Technology, 210 (8). pp. 981-997.

[2] J. Jeswiet, F. Micari, G. Hirt, A. Bramley, J. Duflou, J. Allwood, Asymmetric Single Point Incremental Forming of Sheet Metal, Annals of CIRP Vol. 54/2/2005; pp. 623 – 650.

[3] C. Robert, A. Delamézière, P. Dal Santo, J.L. Batoz, Comparison between incremental deformation theory and flow rule to simulate sheet-metal forming processes, Journal of Materials Processing Technology, Volume 212, Issue 5, May 2012, pp. 1123–1131.

[4] Dejardin, S.; Gelin, J.-C.; Thibaud, S. (2010): On-line thickness measurement in incremental sheet forming process. In: 13th International Conference on Metal Forming, Toyohashi, Japan, September 19-22, pp. 938-941.

[5] H. Meier, C.Magnus, V.Smukala: Impact of superimposed pressure on dieless incremental sheet metal forming with two moving tools, CIRP Annals - Manufacturing Technology, Volume 60, Issue 1. 2011, pp. 327-330.