|

|

BMe Research Grant |

|

Pál Vásárhelyi Doctoral School of Civil Engineering and Earth Sciences

BME ÉPK, Department of Engineering Geology and Geotechnics

Supervisor: Dr. Kopecskó Katalin

Influence of Supplementary Cementing Materials on the Chemical Resistance of Cements

Introducing the research area

In my recent research the influence of two different supplementary cementing materials (SCMs) (metakaolin – MK, silica fume – SF) on the microstructure of cement-based binders was investigated. Furthermore, the behaviour of SCMs containing cement-based binders was examined in corrosive (acidic – sulphuric and acetic acid) circumstances. The reaction mechanisms of the occurred processes were continuously tracked in details, and some more effective application possibilities were analysed and recommended for practical use. My research is of interdisciplinary nature because knowledge of both chemistry and civil engineering are required to create new scientific results.

Brief introduction of the research place

The measurements were carried out at the Budapest University of Technology and Economics, Faculty of Civil Engineering, Department of Construction Materials and Technologies and Department of Engineering Geology and Geotechnics Material Testing Laboratories. NAD (nitrogen adsorption-desorption) measurements were carried out at the Department of Physical Chemistry and Materials Science, Surface Chemistry Laboratory and the scanning electron microscope (SEM) patterns were taken at the Department of Inorganic and Analytical Chemistry.

History and context of the research

Cement and various supplementary cementing materials were widely used in the Roman Empire (Fig.1), but after the fall of the ancient Rome these materials were totally forgotten until the 2nd half of the XIX century.

Fig. 1 Pont du Gard Roman aqueduct (France) [1]

One defined part of the cement can be substituted by another material. This other material is called SCM. Most of the SCMs are industrial by-products (power plant fly ash; glass recovery; silicate industry; iron metallurgy; etc.), and such application is sort of waste recovery. On the other hand, the cement industry produces very large amount of CO2 (7% of the world’s emission) (Fig.2.). That is why the substitution of cement with other materials is very important, because this way the quantity of the cement production can be significantly reduced [2].

Fig. 2. Cement plant in China [3]

Nowadays, the sewage systems and sewage plants are not able to treat the precipitation which is more intensive and of uneven distribution caused by the climate change. Therefore, construction of new systems and plants has become necessary, which cannot be carried out efficiently without SCMs. (Resins used earlier are expensive and need continuous maintenance.) [4].

For the effective application of SCMs it is indispensable to identify the major specific properties SCMs donate. For example, a more compact structure is created by the wide-scaled particle sizes, or some reaction products are more resistant, than others. The examination of these properties is very important, because we need to know the optimal dosage and conditions when applying these materials.

The research goals, open questions

In practice, the application possibilities of SCMs are profoundly investigated. For their successful usage it is essential to examine the chemical reactions and physical processes that occur. In my research I tried to answer the following questions.

● How does the application of the SCMs affect the microstructure?

SCMs have different particle sizes (mainly smaller) from cement, and it generates a more compact structure. Smaller particles fill the gaps between bigger ones (cement). It means that the intrusion of harmful ions and aggressive agents becomes more difficult. In my investigations the degree of compaction and the level of resistance were examined (acidic experiments are related to this question).

● How does the application of SCMs influence the mechanism of cement hydration?

These experiments aimed to define the main effects of SCMs on the hydration mechanism of cement. (The durability and the strength of the structure were both affected by the hydration process.) [5, 6].

● Which is the optimal dosage of SCMs?

This aspect is very important from both practical and economical point of view, because SCMs are more expensive than cement, and any excessive use can cause negative effects (formation of aggregates, micro cracks, shrinkage, etc.).

● How do SCMs containing specimens (cement paste, mortar) behave in special (acidic) circumstances? How does the long-term (360 days) treatment affect them?

The cement paste and mortar specimens were stored under one of the four different circumstances: air, water, sulphuric acid (pH=1) and acetic acid (pH=3). The chemical resistance of these specimens were investigated by thermal-, and phase analysis.

Methods

To evaluate the effect of the SCMs one has to combine experimental methods of chemical engineering and materials science. My own experiments were performed on cement paste and mortar specimens, which were made with Portland cement (type: CEM I 42.5 N), metakaolin (MK), silica fume (SF) and water (in the case of mortar specimens the additive was sand of diameter 0/4 mm).

The specimens were stored under standard circumstances (7 days lime water, and subsequently 21 days on air). After 28 days the samples were subjected to defined circumstances (air/air chamber, acetic acid solution/pH=3, lime water, sulphuric acid solution/pH=1) (Fig. 3-4.).

In the case of cement paste specimens the measurements were carried out until 360 day, however in the case of mortar specimens until 180 days. The aim of this testing period was to follow the hydration mechanisms, and consequently to monitor the changes in the strength properties. This method gives an answer regarding the long-term effects of corrosive circumstances.

Fig. 3. Acidic treatment of cement paste specimens (right: acetic acid - pH=3; left: sulphuric acid - pH=1) [own photos]

Fig. 4. Acidic treatment of mortar specimens (right: acetic acid - pH=3; left: sulphuric acid - pH=1) [own photos]

The following measurements were carried out on cement paste specimens.

1. NAD (nitrogen adsorption-desorption). This measurement provides information on the microstructure (pore size, pore size distribution, pore shape, etc.) of cement paste specimens in the 2-100 nm range. This size range has not been extensively researched, although the transformations and processes, which occur in this range, have significant effects on the whole structure.

2. Measurement of density, bulk density, capillary water absorption, total porosity. These are basic tests which inform us about mass-composition properties.

3. Thermal analysis – derivatograph and X-ray powder diffraction.The phase-composition properties were investigated with these methods. They can provide information on the transformation of the hydrate phases and the microstructure (Fig. 5.). These methods were used to analyse the layers of the specimens which are formed by the acidic treatment as well.

Fig. 5 Derivatograph MOM Q-1500 [own photo]

The following measurements were carried out on mortar specimens.

1. Fresh mortar / consistency test (according to standard MSZ EN 1015-3). Consistency is defined as the mobility or fluidity of mortar. SCMs have significant influence on consistency which is also important in practical use, because both the working time and the energy-input are different in a mixture containing SCMs.

2. Strength tests (based on the standard MSZ EN 1015-11). These tests were carried out on hardened specimens. The optimal application circumstances of the mixtures (maximum value of compressive and flexural tensile strength) could be estimated from the results (Fig. 6).

Fig. 6. Compressive and flexural tensile strength tests [own photos]

3. Density and water absorption tests (based on the standard MSZ EN 1015-10). These basic tests describe the structure of the mortar.

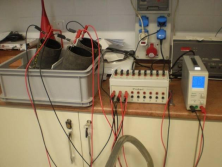

4. Chloride ion migration test (rapid migration method). This method is suitable for the analysis of the permeability of mortar structures. The mortar specimens were immersed in solutions which contained chloride ions. The chloride ions driven by the electric field migrated to and penetrated into the mortar specimens. For compact structures this penetration is moderate. This property is closely related to durability (Fig.7.).

Fig. 7. Test equipment rapid chloride migration test [own photo]

Results

Cement paste specimens

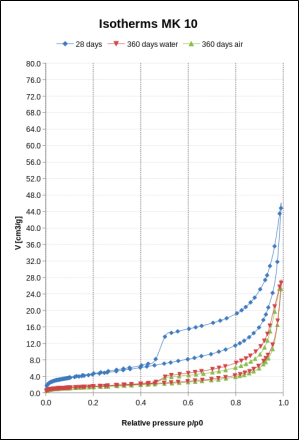

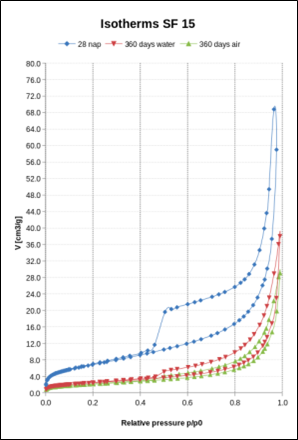

According to the evaluated test results of the NAD measurements it was proven, that the SCMs have significant effects on the microstructure of the cement-based binders in the 2-100 nm size range. Furthermore, it could be stated that the pore structure of the specimens was getting refined with time, because the hysteresis loop was narrower at the age of 360 days, then at the age of 28 days. The total pore volume, the pore size, and the pore shape were also changed by the addition of SCMs.

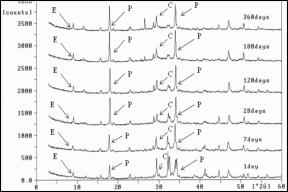

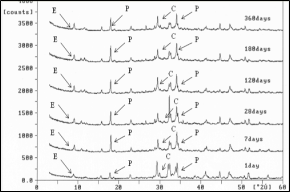

One part of the samples was stored in water and the other on air. The isotherm of the MK10 sample (Fig.8a.) does not suggest a big difference between the two storage conditions. However, in the case of the SF15 samples the difference of the isotherms is more apparent (Fig. 8b.). The reason of these differences is that the SCMs influence the phase transformation during the hydration mechanism. These transformations were followed by thermal analysis and X-ray powder diffraction. Different SCMs cause deviations in phase density, transformation speed, phase distribution, etc. (Fig.9).

Fig. 8. NAD isotherms of SCMs containing cement paste specimens at the age of 28 and 360 days (water, air) (a:MK10; b:SF15)

Fig. 9. Development of the hydration of CEM I 42,5 N cement paste samples without MK (left) and with MK (right) as function of age, X-ray patterns at the age of 1, 7, 28, 120, 180, 360 days (air cured specimens) (Notations: E-ettringite, P-portlandite, C-clinkers)

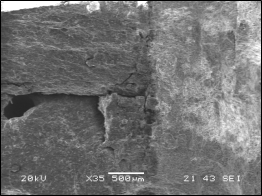

In acidic circumstances the cement paste specimens degraded in layers. The composition of these layers were analysed by thermal analysis and X-ray powder diffraction. During these measurements the degradation processes (which were caused by acids) were followed (Fig.10.). These results were completed with SEM (scanning electron microscope) patterns (Fig.11).

Fig. 10. The degraded specimens after acidic treatment (right: specimens from acetic acid; left: specimens from sulphuric acid)

Fig. 11. SEM pattern of a SCM containing cement paste specimen (MK17, acetic acid, 360 days) [own pattern]

Mortar specimens

The consistency of the SCM containing mortars was different than the references. The surface of the mixture was increased by the SCMs. The differences were caused by the variant particle sizes and particle shapes (the MK has lamellar; the SF has spherical, while the cement has uneven, irregular particle shape).

The flexural tensile strength was increased by the SCMs. The compressive strength was affected by the moisture content of the specimens. The water in the capillary system was pressurized whereas the water cannot be compressed. The reason is that the transverse deformation of the samples increased, and the deterioration occurred yet at lower forces.

Water absorption rates of the dry specimens were higher, because they shrank, and some micro cracks occurred. That is why the porosity and the water absorption value increased and the hydration process was blocked. In the case of specimens stored in water, the hydration was continuous and the permeability decreased.

According to the results of the chloride ion migration tests, it was concluded that the diffusion decreases with the aging of specimens. The diffusion coefficient and the porosity were lower, which indicated that the formation of hydrate products was continuous. Furthermore, the permeability has been decreased by the more compact structure caused by the application of SCMs.

Expected impact, future plans

Further research focuses on the optimization of the practical application of SCMs. This includes the determination of the optimal dosage, and the definition of the most appropriate areas of applicability. It is essential to perform tests under real circumstances (sewage treatment plants, canals, sewage systems, etc.). I also aim to create a numerical model which would allow more accurate design when using SCMs.

My investigation is an important part of a currently running OTKA research, and it is closely related to an NVKP project. The results are being published in various journals and at conferences both in Hungarian and in English. One of my articles won a “Best Paper Award” in a PhD conference in Cluj-Napoca in 2012.

List of corresponding own publications

● Kopecskó Katalin, Mlinárik Lilla , Lublóy Éva , Salem G Nehme , Balázs L György: A beton kémiai ellenállóképességének fokozása, In: Köllő Gábor (eds.) XXII. Nemzetközi Építéstudományi Konferencia . 236 p., Csíksomlyó , Romania , 31.05.2018 - 03.06.2018 Erdélyi Magyar Műszaki Tudományos Társaság (EMT), pp. 106-112.

● Lilla Mlinárik, Katalin Kopecskó: The influence of combined application of two SCMs on the corrosion and acid attack durability of mortars PERIODICA POLYTECHNICA-CIVIL ENGINEERING 61:(2) pp. 313-321. (2017)

● Kopecskó Katalin, Mlinárik Lilla: Fázisanalitikai módszerek szerepe a cementkő kémiai ellenálló képességének vizsgálatában, In: Köllő Gábor (eds) XX. Nemzetközi Építéstudományi Konferencia: ÉPKO 2016 =20th International conference on civil engineering and architecture, Csíksomlyó , Romania, 01.06.2016 - 05.06.2016. Cluj-Napoca: Erdélyi Magyar Műszaki Tudományos Társaság (EMT), pp. 125-129.

● Lilla Mlinarik, Katalin Kopecskó: Influence of severe acidic circumstances on hydration and microstructure of cementitious materials, In: Koichi Maekawa , Akio Kasuga , Jun Yamazaki (eds) Proceedings of 11th fib International PHD Symposium in Civil Engineering . 927 p. Tokyo, Japan, 29.08.2016 - 31.18.2016. Tokyo: University of Tokyo, 2016. pp. 261-268. (ISBN:978-4-9909148-0-6)

● Mlinárik L, Kopecskó K, Borosnyói A: Properties of cement mortars in fresh and hardened condition influenced by combined application of SCMs, ÉPÍTŐANYAG 68:(2) pp. 62-66. (2016)

● L Mlinárik, K Kopecskó: Effects of long-term acidic treatment on the hydration mechanism of metakaolin (MK) containing cement pastes, In: J Bastien, N. Rouleau, M. Fiset, M. Thomassin (eds.), The 10th fib International PhD Symposium in Civil Engineering 650 p., Québec, Canada, 2014.07.21 -2014.07.23., pp. 79-84. (ISBN:978-2-9806762-1-5)

● L Mlinárik , K Kopecskó: Impact of metakaolin - a new supplementary material - on the hydration mechanism of cements, ACTA TECHNICA NAPOCENSIS - CIVIL ENGINEERING & ARCHITECTURE 56:(2) pp. 100-110. (2013)

● L Mlinárik, K Kopecskó: Influence of metakaolin on chemical resistance of concrete, IOP CONFERENCE SERIES: MATERIALS SCIENCE AND ENGINEERING 47: Paper 012014. 6 p. (2013), (WoS, Scopus)

● A Borosnyói, P Kara, L Mlinárik, K Kase: Performance of waste glass powder (WGP) supplementary cementitious material (SCM) – Workability and compressive strength, ÉPÍTŐANYAG 65:(3) pp. 90-94. (2013)

● Kopecskó K, Mlinárik L: Metakaolin a betonban, BETON XXII.:(3-4.) pp. 18-21. (2014)

● Mlinárik L, Kopecskó K: Influence of supplementary materials on chemical resistance and hydration of concrete, In: Cosmin G Chiorean (eds.), Proceedings of the First international conference for PhD students in Civil Engineering, Cluj-Napoca, Romania, 2012.11.04 -2012.11.07., pp. 456-466. (ISBN:978-973-757-710-8)

● Mlinárik L, Kopecskó K: Cement hydration in the presence of metakaolin, In: Józsa János, Lovas Tamás, Németh Róbert (eds.), Proceedings of the Second Conference of Junior Researchers in Civil Engineering, Budapest, Hungary, 17.06.2013 - 18.06.2013.. Budapesti Műszaki és Gazdaságtudományi Egyetem, paper. 39

● Mlinárik L, Kopecskó K: Influence of supplementary materials on chemical resistance of concrete, In: Józsa János, Lovas Tamás, Németh Róbert (eds.), Proceedings of the Conference of Junior Researchers in Civil Engineering, Budapest, Hungary, 06.19.2012. -20.06.2012. Budapesti Műszaki és Gazdaságtudományi Egyetem, pp. 126-134. , (ISBN:978-963-313-061-2)

● Mlinárik L, Kopecskó K: Cementek hidratációjának változása metakaolin cement kiegészítő anyag jelenlétében, In: Köllő Gábor (eds), Erdélyi Magyar Műszaki Tudományos Társaság XVII. Nemzetközi Építéstudományi Konferencia, Csíksomlyó , Romania , 13.06.2013 - 16.06.2013. , pp. 259-263.

● Minárik L, Kopecskó K: Metakaolin - egy új cement kiegészítő anyag, In: Török Ákos, Vásárhelyi Balázs (eds), Mérnökgeológia-Kőzetmechanika 2011. 394 p., Budapest, Hungary, 16.01.2012., pp. 357-362., (ISBN:978-615-5086-04-5)

List of own publications

● Németh Gabriella, Mlinárik Lilla, Török Ákos: Adsorption and chemical precipitation of lead and zinc from contaminated solutions in porous rocks: Possible application in environmental protection, JOURNAL OF AFRICAN EARTH SCIENCES 122: pp. 98-106. (2016)

● Trájer Attila János, Hammer Tamás, Mlinárik Lilla, Bede-Fazekas Ákos, Padisák Judit: The neogene-quaternary evolution of the karst landscape of the Veszprém plateau based on the study of Meggyespuszta paleodoline, Hungary, ACTA CARSOLOGICA 44:(2) pp. 177-190. (2015)

● T K Simon, L Mlinárik, V Vargha: Effect of water vapor on the compressive strength of a mineral wool insulation board, JOURNAL OF BUILDING PHYSICS 1: pp. 1-10. (2015), published online doi: 10.1177/1744259115588744

● A Trájer , L Mlinárik , P Juhász , Á Bede-Fazekas: The combined impact of urban heat island, thermal bridge effect of buildings and future climate change on the potential overwintering of Phlebotomus species in a Central European metropolis, APPLIED ECOLOGY AND ENVIRONMENTAL RESEARCH 12:(4) pp. 887-908. (2014)

● G Németh, L Mlinárik, Á Török: Lead (II) and zinc (II) ions removal capacity of coarse limestone and rhyolite tuff from aqueous solutions, ÉPÍTŐANYAG 65:(3) pp. 86-89. (2013)

● Trájer A, Bede-Fazekas Á, Juhász P, Mlinárik L: A klímaváltozás és a városi hősziget-effektus együttes hatása a lepkeszúnyog-fajok által terjesztett emberi megbetegedésekre, ISKOLAKULTÚRA 24:(11-12) pp. 48-68. (2014)

● Németh G, Mlinárik L, Török Á: Riolittufa és durva mészkő oldott állapotú ólom (II) ion megkötési képességének vizsgálata, In: Török Á, Görög P, Vásárhelyi B (eds.) Mérnökgeológia-Kőzetmechanika 2013. 366 p., Budapest, Hungary, 16.11.2013. , pp. 43-48., (ISBN:978-615-5086-06-9)

List of references

[1]INFRASTRUCTURE, COMMUNICATIONS AND ENERGY IN ANCIENT ROMAN, last visit: 2018.06.15.

[2] R Siddique, J Klaus: Influence of metakaolin on the properties of mortar and concrete: A review, Applied Clay Science 43, p.392–400. (2009)

[3]Alister Doyle: Environmentalists divided about burying CO2, Reuters (2008), last visit: 2018.06.16.

[4] B Hillemeier, R Hüttl: Säureresistenter Beton mit einstellbarer Festigkeit für den höchsten Kühlturm der Welt, Ulmer Beton- und Fertigteil-Tage Conference, Proceedings of the conference, Ulm, 1-3. February 2000, p.142-157, (2000)

[5] E Moulin, P Blanco, D Sorrentino: Influence of key cement chemical parameters on the properties of metakaolin blended cement, Cement & Concrete Composites 23, p.463-469(2001)

[6] M Said-Mansour, E Kadri, S Kenai, M Ghrici, R Bennaceur: Influence of calcined kaolin on mortar properties”, Construction and Building Materials vol.25. p.2275-2282, (2011)