|

|

BMe Research Grant |

|

Géza Pattantyús-Ábrahám Doctoral School of Mechanical Engineering

BME GPK, Department of Polymer Engineering

Supervisor: Dr. Molnár Kolos

A self-powered, changeable, breathable, and smart mask filter based on triboelectric nanogenerators for respiration monitoring

Introducing the research area

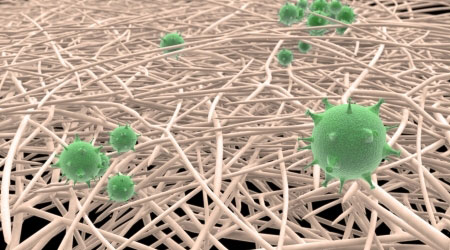

There are various biological aerosol particles in the outdoor air, including viruses, bacterial cells, fungal spores, fragments, and pollen grains, which may cause health issues, especially infectious diseases [1]. These particles, due to their small size can easily penetrate the human respiratory system and cause flu, colds, pneumonia, and others. For example, the diameter of the 2019-novel coronavirus (nCoV) particles varies from about 60 to 140 nm [2]. It has been turned out that surgical masks made of melt-blown microfibers can prevent transmission of human CoVs from symptomatic individuals. However, in comparison with melt-blown fibers commonly used in masks, nanofibers have demonstrated huge prospects in creating high-performance air filters, which is ascribed to their favorable characteristics of reduced diameters, robust mechanical properties, and ease of scalable preparation from various raw materials. Therefore, the electrospun nanofiber web is an alternative candidate as a filtration media because of its small pore size, small diameter, and large specific surface area (Figure 1). The increasing use of masks made it urgent to develop intelligent masks capable of monitoring the condition of the human respiratory system, which is an important indicator of human health, especially in patients infected with the Covid-19 virus. In addition, it is important to develop a self-powered and comfortable-to-wear sensor.

Figure 1 The illustration of how the nanofiber filter (in white) captures the virus (in green) [3]

Brief introduction of the research place

My research work is carried out at the Department of Polymer Engineering of BME. The quality and environmental policy of our department includes the full implementation of the ISO 9001:2015 and ISO 14001:2015 standards. Our Department was awarded the “Greenest Department” title of the University in 2010. Besides, our department issued the journal entitled eXPRESS Polymer Letters with an impact factor of 3.083 (Thomson Reuters) that is the highest value among Hungarian periodicals.

History and context of the research

Electrospinning is a technology to produce nanofibers through the application of electric field force to a polymer solution or melt. The use of electric field force for generating droplets from fluids dates back to the late 1800s [4]. Until the 1990s, electrospinning attracted the interest of many researchers [5] because nanofibers produced by electrospinning have large surface to volume ratio, superior strength, and high porosity. Besides, electrospinning is the only method by which mass production from various polymers can be realized [6].

Triboelectric nanogenerator (TENG) is a newly developed energy-harvesting technology that can convert ubiquitous mechanical energy into precious electricity based on the coupling effect of contact electrification and electrostatic induction [7]. Nanofibers have been used for surface triboelectrification due to their ultra-thin, very large specific surface diameter, excellent flexibility, adjustable porosity, and controllable compositions [8]. Therefore, nanofibers were used as triboelectrification layers to generate voltage signals in my research.

Breathing is an important physiological process in living organisms. Respiratory rate is a vital sign used to monitor the progression of the illness, and an abnormal respiratory rate is an important marker of serious illness. The existing devices for monitoring respiratory rate are usually based on respiratory sounds, respiratory airflow, respiratory-related chest or abdominal movements, respiratory CO2 emission, oximetry probe SpO2, and electrocardiogram (ECG) [9]. Moreover, there are non-contact respiration rate monitoring systems that use radar sensors, optical sensors, and thermal sensors. With the increasing use of masks during the pandemic, it is urgent to combine a respiration rate monitoring system with a mask, which can be a convenient way for detecting the respiratory conditions of the patients infected by Covid-19.

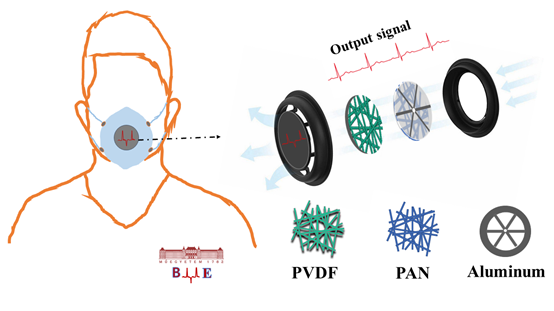

The research goals, open questions

Although nanofibers have already been used to make TENGs, and some of TENGs made from polymers can also be used as a breathing sensor, there has been little research where a TENG can be used as a filter and a respiration monitoring system simultaneously. Therefore, the aim of my research is to develop a smart mask filter, which not only has high filtration efficiency but is also capable of monitoring respiration (Figure 2). My first task was to create a TENG configuration that can generate voltage signals based on different breathing parameters. To obtain stable and obvious voltage signals, the structural parameters of TENG need to be optimized. However, during the recording of the voltage signals, the shape of the signal spectrums was not as periodic as that of the theoretical ones due to the noise from the device. For this reason, I had to optimize the scanning interval time of the device to eliminate the disturbances caused by noise. The long-term stability of voltage output from the TENG is very important for TENG filter applications. Furthermore, in my research, the filtration efficiency of the nanofiber filter will also be examined and compared with the commercially available KN95 masks. Finally, the output voltage signals obtained from the TENG were analyzed based on the different respiratory parameters to detect the respiratory state.

Figure 2 The demonstration of the structure of the smart mask filter

Methods

Preparation of nanofibers via electrospinning

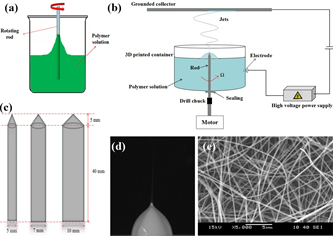

Needle electrospinning is the most common method for making nanofibers. However, the biggest issue is the needle clogging, especially with some highly viscous polymer solutions. To address the problem, I proposed a new electrospinning method utilizing the Weissenberg effect. We named it rod-climbing electrospinning (RC-ES), where a relatively steady and stable meniscus is formed during the electrospinning process [S2]. Nanofibers could be fabricated from the rod tip of a self-designed and constructed setup (Figure 3b). As the rod rotated, the polymer solution climbed up onto the rod tip due to the Weissenberg effect (Figure 3a). Then the solution was charged using high voltage until the voltage reached a threshold value, when a polymer jet was ejected from the tip of liquid meniscus (Figure 3d). It can also produce nanofibers from relatively viscous polymer solutions (viscosity > 13.05 Pa·s), which cannot be electrospun with needle electrospinning. In my research, the nanofiber membranes were produced from Polyvinylidene fluoride (PVDF) and Polyacrylonitrile (PAN) powder dissolved into the solvent of n,n-dimethylformamide (DMF), which were used as the negative and positive contact surface in the TENGs to generate voltage signals.

Figure 3 (a) Schematics of Weissenberg effect, (b) schematic drawing of the rod-climbing electrospinning (RCES), (c) rods used for electrospinning, (d) optical image of the meniscus in electrospinning process, (e) SEM image of nanofibers produced by RCES

Fabrication of TENGs

To develop a convenient and simple way to connect the TENG sensor with a medical ventilator, two funnels were 3D printed from polylactic acid (PLA). The funnels were used as the structural framework for TENG. An aluminum tape was then adhered on the top of the two funnels. A piece of PVDF and PAN nanofiber membrane was then cut into 30 mm diameter circles and glued to one side of the Aluminum tape to construct the TENG. 1 mm thick diameter thick circular rings were also 3D printed from PLA. They were placed between two funnels to adjust the distance between the two nanofiber membranes. Finally, the two funnels and ring spacers were assembled together with screws. When the sensor was subjected to inspiration, the nanofiber membrane on the funnel top with a bigger hole can come into contact with another nanofiber membrane of the other funnel. However, during the exhalation process, the nanofiber membranes were deformed and blown up in the opposite direction of inhalation; they could no longer contact each other due to the different degree deformation of the nanofiber membranes.

Characterization and measurements

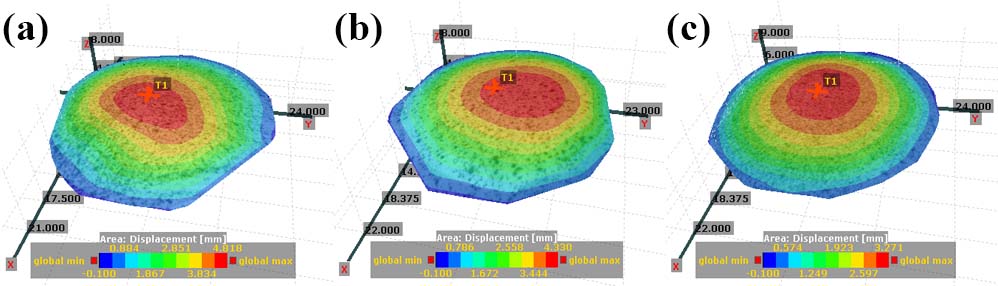

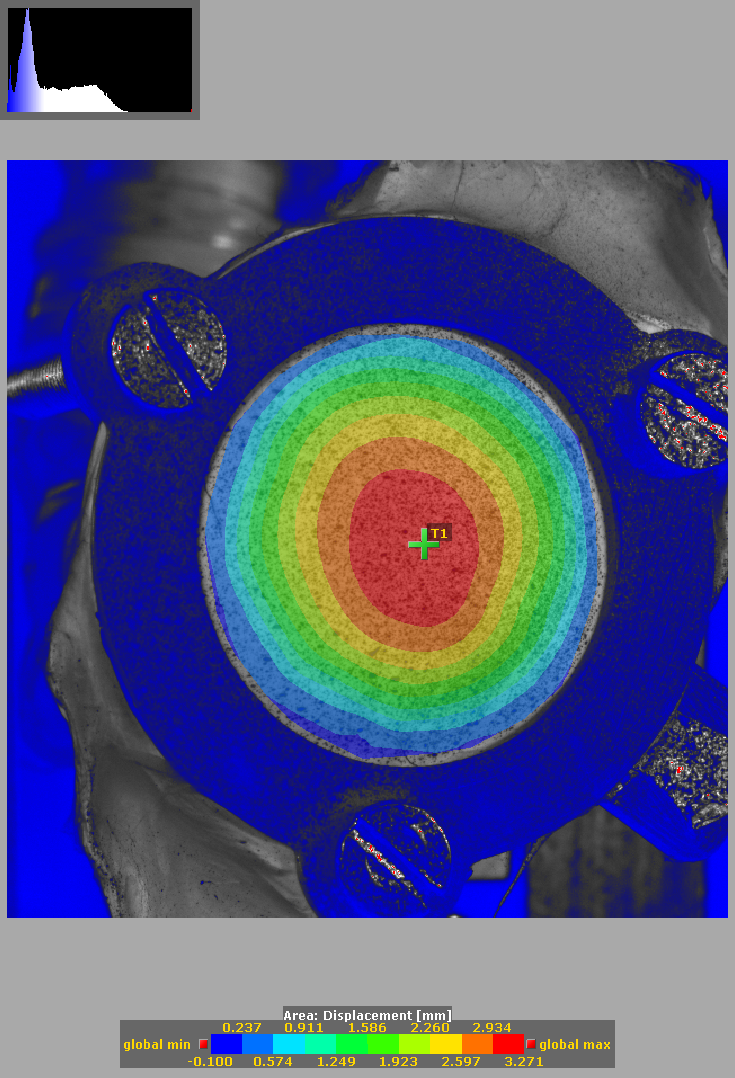

3D digital image correlation (3D-DIC) was used to detect the deformation of nanofiber membranes when they were blown up, as this is a useful method to detect the deformation of small test surfaces. During the deformation process, three-dimensional displacement fields (Figure 4) could be obtained. The morphology of the nanofibers was investigated by scanning electron microscope (JEOL-JSM-6380 LA, Japan). The particle filtering properties of the nanoporous filters were analyzed by an aerosol particle counter (Lasair III 310C, Artisan Technology Group, USA). The electrical signals were acquired with a digital multimeter (Agilent 34870A, America). During the electrical signals recording process, a human breathing process was simulated using a ventilator (developed by BME professors and researchers) with controllable respiratory parameters.

Figure 4 The 3D real-time deformation of nanofiber membrane during blow-up (the diameter of the specimen was 30 mm)

Results

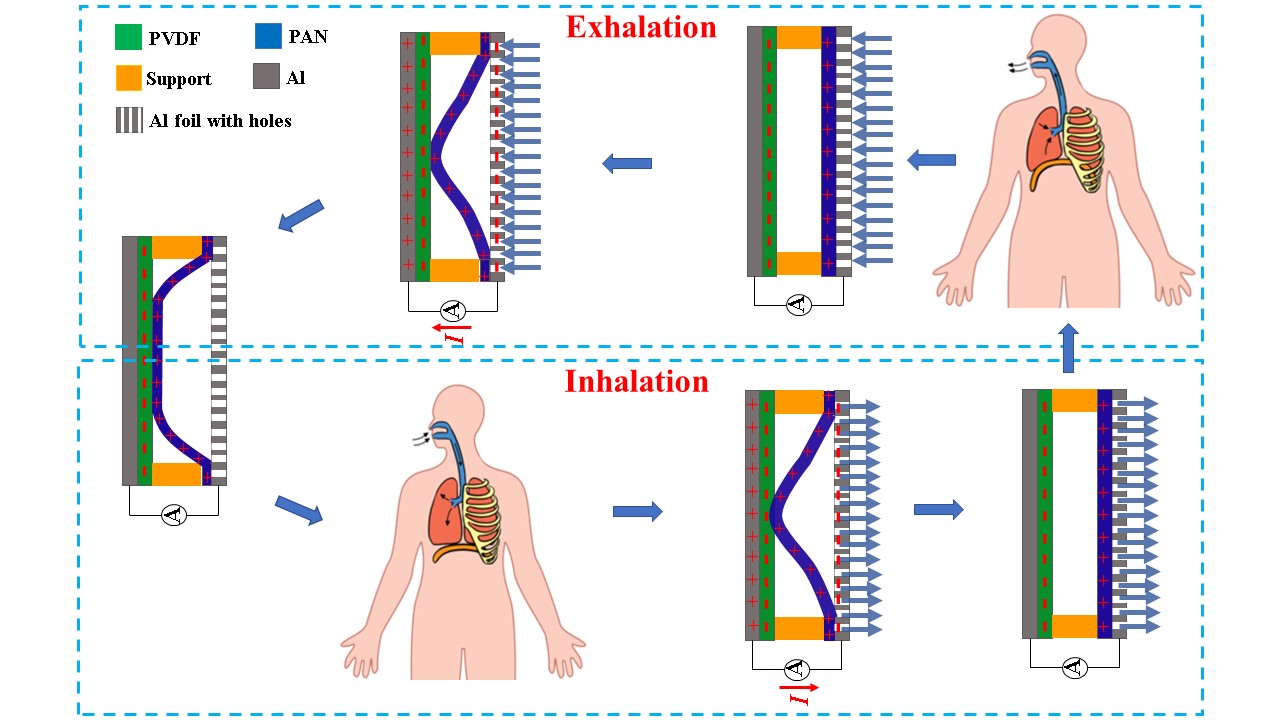

Principle of operation of the TENG

The operating mechanism of the TENG is based on the coupling effect of contact electrification and electrostatic induction (Figure 5). In their original state, there is no charge transport from the two friction layers. During the breath cycles, a voltage output can be generated from the TENG by exhalation and inhalation. When exhalation occurs, the PAN nanofiber layer is blown up to contact the PVDF layer. In this contact process, the PAN nanofiber layer tends to electron loss and becomes positive, while the PVDF layer tends to gain electrons to generate negative charges. At the start of inhalation, the PAN layer returns to its original position and the two layers separate. Due to the electric potential difference between two electrodes, the transported electrons flow back from the PVDF layer to the PAN layer.

Figure 5 Voltage generation mechanism of the TENG

Deformation measurement of the PAN nanofiber membrane

The deformation of the PAN nanofiber membrane at different thicknesses was measured by 3D DIC method. The thickness was controlled by the electrospinning time, which was set to 40 min, 80 min, and 120 min. The center point has the maximum deformation with the highest displacement. It shows that the displacement of the center point increased with decreasing nanofiber membrane thickness (Figure 6). The deformation results served as a reference for setting the distance between the two layers.

Figure 6 3D real-time measured photographs showing the out-of-plane displacement of nanofiber membrane with different thicknesses: (a) 40 min, (b) 80 min, (c) 120 min

Particle filtration properties of nanofiber membrane

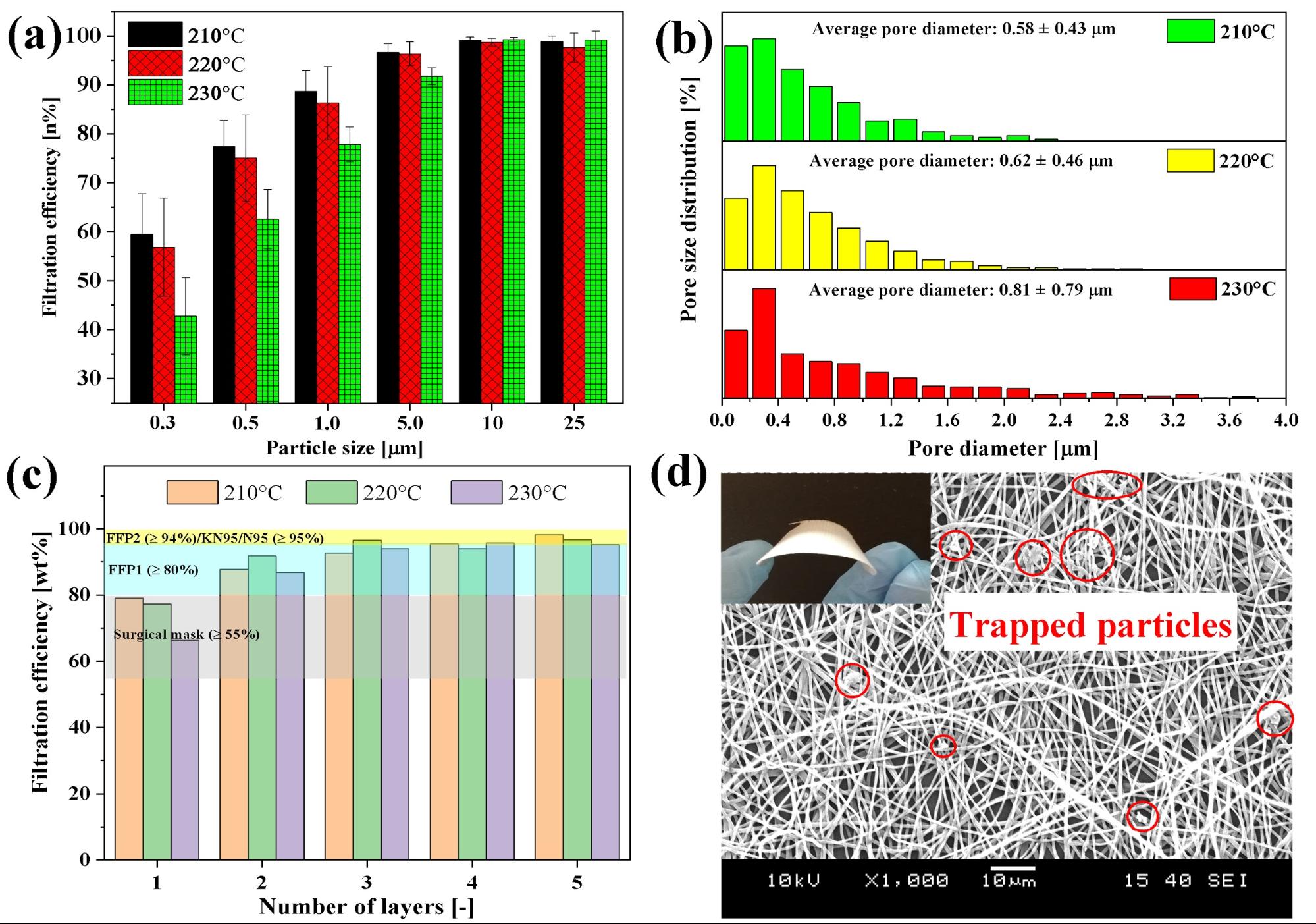

In my previous research, I combined nanofibers with 3D printed mesh as a supportive structure to impart the nanofiber filter with good mechanical properties. During the 3D printing process, the higher nozzle temperature can increase the tensile strength and decrease the breaking strain because of the better fusion between the adjacent layers. A thin, single layer of nanofibers can outperform a classical surgical mask (Figure 7). Furthermore, the multiple layers of nanofibers can have a similar filtration performance as KN95/N95 and FFP2 filters [S3]. The results showed that nanofiber membrane is a good material for mask filters.

Figure 7 (A) Filtration efficiency of nanoporous filters with various particle size, (B) pore size distribution of nanoporous filter printed with different temperatures, (C) the filtration efficiency (wt%) of nanoporous filters with various stacking layers, (D) scanning electron microscope image of the nanoporous filter after filtration. Inset is the bent single-layered filter.

Respiratory sensing with TENG

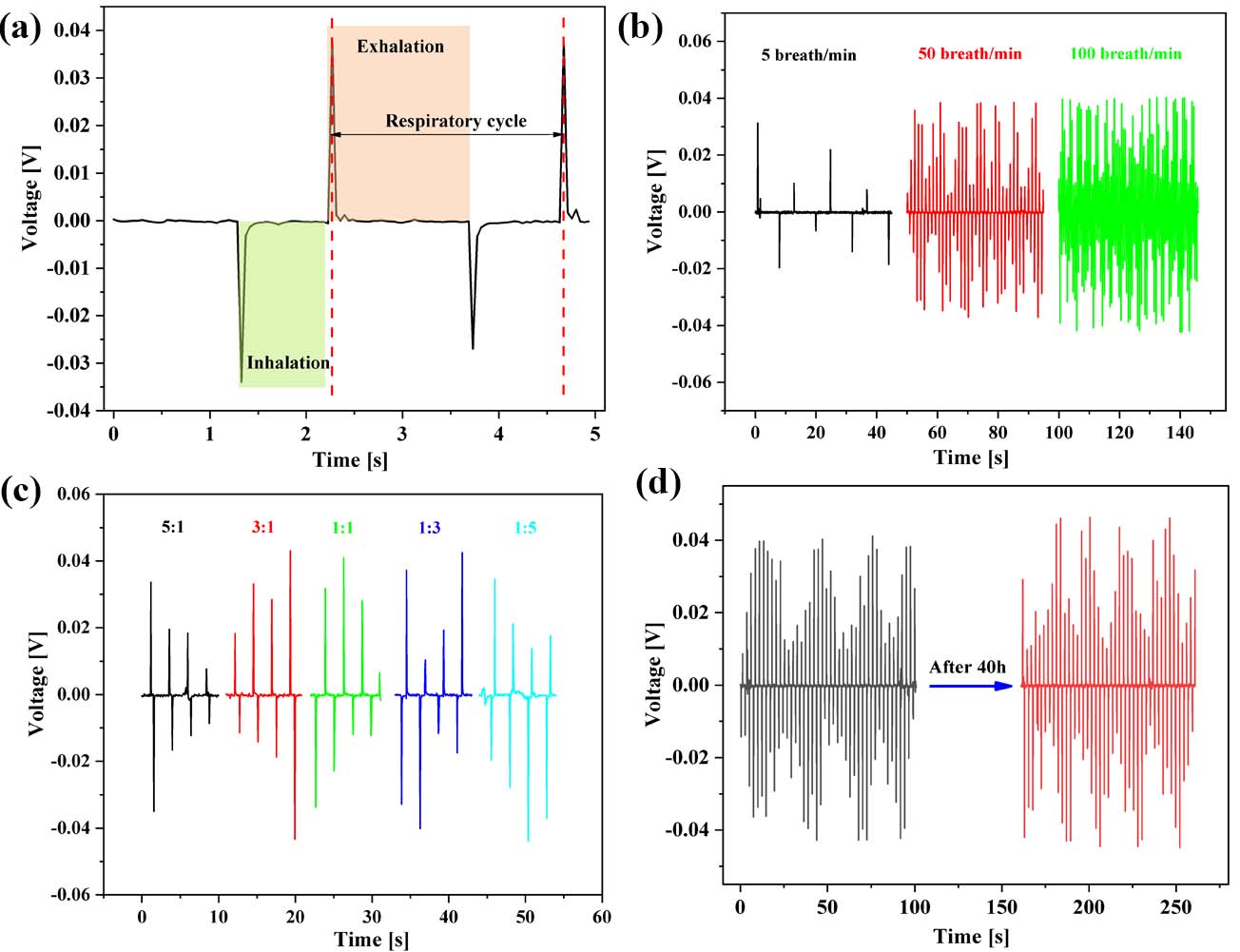

The different respiratory parameters (respiratory frequency and respiratory quotient) were recorded successfully with the TENG sensor. Respiratory frequency can be represented by the time interval between adjacent positive (or negative) peaks. Respiratory quotients can be calculated from exhalation time and inhalation time. By adjusting respiratory parameters on a ventilator, the obtained signals showed consistent respiratory results with the input respiratory parameters of the ventilator. The durability and stability of the TENGs are also crucial and important factors for their practical application. There was no noticeable change in output voltage signals after 40 hours of use, demonstrating that the TENG has excellent durability and reliability (Figure 8).

Figure 8 The output voltage of the TENGs according to different breathing parameters: (a) characterization of one respiratory cycle, (b) different respiratory frequency, (c) different quotients (the ratio of inhalation and exhalation), (d) the durability of the TENG

Expected impact and further research

Nanofibers can be used in the mask industry as high-performance filtration media to filtrate nanosized particles because of their large surface area, high porosity with small pore size. With a very thin nanofiber membrane, they can have the same filtration efficiency as FFP2/ FFP3 masks. In addition, the mask itself can also be used as a sensor to monitor the user’s breathing. In a pandemic time, the development of a smart mask with respiratory sensing is urgent and critical. Especially for the patients infected with Covid-19, who must wear the mask at all time to protect themselves and prevent the transmission of the virus. A smart mask could provide a critical early-warning sign when a patient’s condition worsens, receives anesthetic or opioid pain relief. In addition, being a self-powered sensor that does not require a power supply for its operating state, it is very convenient and comfortable for users.

Publications, references, links

List of corresponding publications

[S1] H. He, Y. Wang, B. Farkas, Z. K. Nagy, K. Molnar. Analysis and prediction of the diameter and orientation of AC electrospun nanofibers by response surface methodology. Materials and Design (IF: 6.289), 108902 (2020).

[S2] H. He, M. Gao, D. Torok, K. Molnar. Self-feeding electrospinning method based on the Weissenberg effect. Polymer (IF: 4.231), 190, 12247 (2020).

[S3] H. He, M. Gao, B. Illés, K. Molnar. Three-dimensional Printed and Electrospun, Transparent, Hierarchical Polylactic-Acid Mask Nanoporous Filter. International Journal of Bioprinting (Q1), 6 (4), 278 (2020).

[S4] Y. Kara, H. He, K. Molnar. Shear-aided high-throughput electrospinning: A needleless method with enhanced jet formation. Journal of Applied Polymer Science (IF: 2.52), 49104 (2020).

[S5] Z. Zhang, H. He, W. Fu, D. Ji, S. Ramakrishna. Electro-Hydrodynamic Direct-Writing Technology toward Patterned Ultra-Thin Fibers: Advances, Materials and Applications. Nano Today (IF: 16.907), 25, 100942 (2020).

[S6] Z.Zhang, D.Ji, H. He, S. Ramakrishna. Electrospun Untrafine Fibers for Advanced Face Masks. Materials Science & Engineering R (IF: 26.625), 143, 100594 (2021).

[S7] H. He, Y. Kara, K. Molnar. In situ viscosity-controlled electrospinning with a low threshold voltage. Macromolecular Materials and Engineering (IF: 3.853), 304 (11), 1900349 (2019).

[S8] H. He, Y. Kara, K. Molnar. Effect of needle characteristic on fibrous PEO produced by electrospinning. Resolution and Discovery, 4 (1), 7-11 (2019).

[S9] H. He, C Liu, K Molnar. A novel needleless electrospinning system using a moving conventional yarn as the spinneret. Fibers and Polymers [IF: 1.079], 19 (7), 1472–1478 (2018).

[S10] C. Liu, H. He, R. Sun, Y. Feng, Q. Wang. Preparation of continuous nanofiber core-spun yarn by a novel covering method, Materials and Design (IF: 6.289), 112, 456–461 (2016).

[S11] C. Liu, Y. Feng, H. He, J. Zhang, R. Sun, M. Chen. Effect of carbonization temperature on the properties of aligned electrospun polyacrylonitrile carbon nanofibers. Materials and Design (IF: 6.289), 85, 483–486 (2015).

[S12] H. He, K. Molnar. Fabrication of 3D printed nanocomposites interleaved with electrospun nanofibers. Additive Manufacturing. Accepted (2021).

[S13] H. He, Jian Guo, Balazs Illes, Attila Geczy, Balazs Istok, Viktor Hlvia, Daniel Torok, Istvan Harmati, Kolos Molnar. Monitoring multiple respiration indices via a smart nanofibrous mask filter based on triboelectric nanogenerator. Advanced Science. Submitted.

[S14] H. He, Jian Guo, Kolos Molnar. Triboelectric respiration monitoring sensor and a face mask comprising such as a triboelectric respiration monitoring sensor. Patent application, Filed, P2100102, Hungary (2021).

List of references

[1] A. Balazy, M. Toivola, A. Adhikari, S.K. Sivasubramani, T. Reponen, S.A. Grinshpun, Do N95 respirators provide 95% protection level against airborne viruses, and how adequate are surgical masks?, Am J Infect Control, 34(2), 51–7 (2006).

[2] N. Zhu, D. Zhang, W. Wang, X. Li, B. Yang, J. Song, X. Zhao, B. Huang, W. Shi, R. Lu, P. Niu, F. Zhan, X. Ma, D. Wang, W. Xu, G. Wu, G.F. Gao, W. Tan, I. China Novel Coronavirus, T. Research, A Novel Coronavirus from Patients with Pneumonia in China, 2019, N Engl J Med, 382(8), 727–733, (2020)

[3] https://www.nanowerk.com/news2/newsid=35013.php.

[4] J. F. Cooley. Apparatus for electrically dispersing fluids. US patent 69263 (1902).

[5] T. Subbiah, G. S., Bhat, R. W., Tock. Electrospinning of nanofibers. Journal of Applied Polymer Science, 96 (2), 557–569 (2005).

[6] Z.M. Huanga, Y.Z. Zhang, M. Kotak, S. Ramakrishnab. A review on polymer nanofibers by electrospinning and their applications in nanocomposites. Composites Science and Technology, 63, 2223–2253 (2003).

[7] X. Peng, K. Dong, C. Ye, Y. Jiang, S. Zhai, R. Cheng, D. Liu, X. Gao, J. Wang, Z.L. Wang. A breathable, biodegradable, antibacterial, and self-powered electronic skin based on all-nanofiber triboelectric nanogenerators, Science Advance, 6, 9624 (2020).

[8] Z. Li, J. Shen, I. Abdalla, J. Yu, B. Ding. Nanofibrous membrane constructed wearable triboelectric nanogenerator for high performance biomechanical energy harvesting, Nano Energy, 36, 341–348 (2017).

[9] F.Q. Al-Khalidi, R. Saatchi, D. Burke, H. Elphick, S. Tan. Respiration rate monitoring methods: a review. Pediatr. Pulmonol., 46(6), 523–529 (2011).

.